13. INSTALLATION

13-5

13.3.2 Transom mount transducer

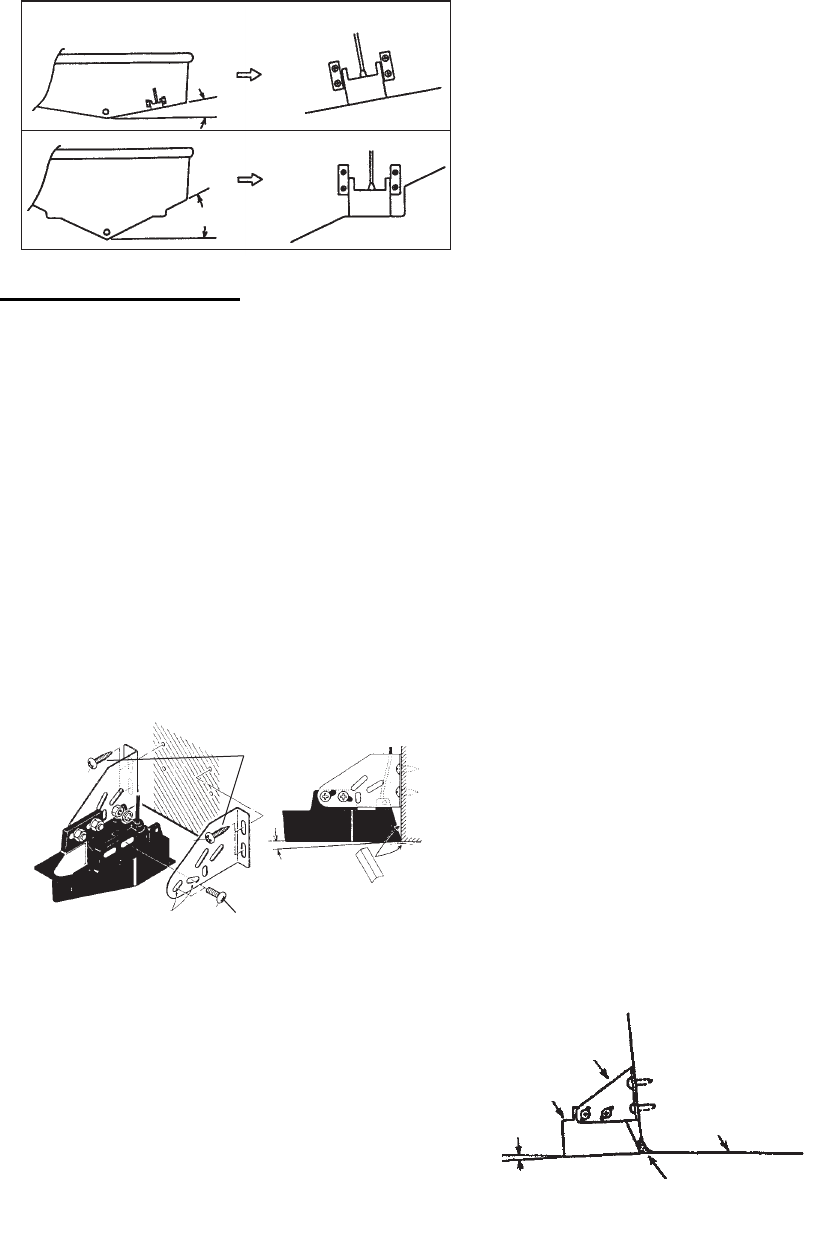

The optional transom mount transducer is very commonly employed, usually on rela-

tively small I/O or outboard boats. Do not use this method on an inboard motor boat

because turbulence is created by the propeller ahead of the transducer.

DO NOT overtighten screws, to prevent damage to the transducer.

Installation procedure

A suitable mounting location is at least 50 cm away from the engine and where the

water flow is smooth.

1. Drill four pilot holes for self-tapping screw (5×20) in the mounting location.

2. Coat the threads of the self-tapping screws (5x14) for the transducer with silicone

sealant for waterproofing. Attach the transducer to the mounting location with the

self-tapping screws.

3. Adjust the transducer position so the transducer faces right to the bottom. If nec-

essary, to improve water flow and minimize air bubbles staying on the transducer

face, incline the transducer about 5° at the rear. This may require a certain amount

of experimentation for fine tuning at high cruising speeds.

4. Tape the location shown in the figure below.

5. Fill the gap between the wedge front of

the transducer and transom with epoxy

material to eliminate any air spaces.

6. After the epoxy hardens, remove the

tape.

Transom

Transom

Stripe

Parallel with hull

Mount at the stripe.

Less than 10°

Over 10°

5x20

M5x14

5°

Taping

Bracket

Transducer

Hull

2 to 5°

Epoxy material