19

THROTTLE CONTROL MAINTENANCE

CAUTION:

• Do not operate the earth auger without a rubber boot assembly in proper condition mounted in posit ion on the throttle control. Without the use

of a proper rubber boot assembly, foreign materials may be gathered and restrict the movement of the internal components, reduce operator

control of the earth auger and result in property damage and/or personal injury.

Interval of Inspection: Daily (every 8 operating hours)

Every 8 hours of actual operation and whenever the throttle cable is replaced, the following maintenance program is to be followed.

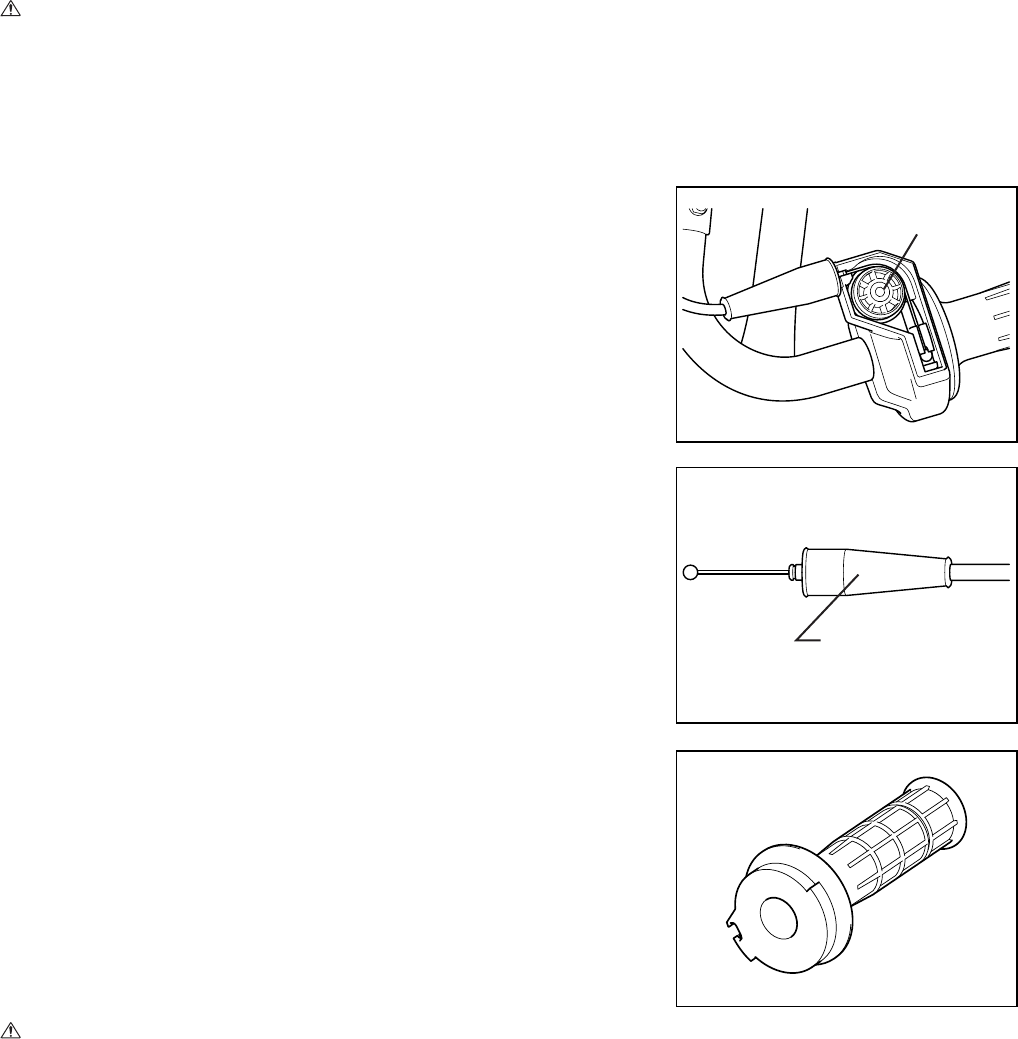

1) Remove the plastic cover to properly inspect the internal components. Any worn or dam-

aged component must be replaced with an approved replacement part only.

2) Normal use produces a wear pattern by the braided inner cable into the idler pulley. Maxi-

mum allowable groove depth wear created by the throttle cable is 1 mm (0.045"). Replace

the idler pulley when it becomes worn more than this limit.

3) Inspect the braided inner cable on a regular basis for excessive wear in the area of direct

contact with the idler pulley. Replace the throttle cable if it is abnormally worn.

4) Inspect the barrel end of the braided inner cable for proper retention on a regular basis. A

properly retained barrel end has no relative movement between the barrel end itself and

the inner cable. If there is any relative movement between them, replace the throttle cable.

5) Inspect the receptacle area of the throttle control which retains the barrel end of the

braided inner cable on a regular basis. A properly fitted barrel fitting must have complete

freedom of movement with no binding restrictions or excessive play due to wear. A barrel

fitting which is binding within the receptacle must be discarded in case of a replacement of

throttle cable.

If receptacle is worn excessively, replace the specific component assembly.

6) The rubber boot assembly protects the internal components of the throttle control from for-

eign material. The service life of the boot assembly may be extended by an appropriate

inspection and maintenance on a regular basis.

7) Inspect the handle grip on a regular basis to check if it is properly secured to the throttle

control.

Replace the throttle control if it fits loose or becomes worn or torn by usage.

AUGER BIT MAINTENANCE

WARNING:

• Do not operate the auger bit which has a bent or damaged axle with a total indicated runout exceeding the maximum allowable limit. Exces-

sive auger wobble may reduce operator control, resulting in property damage and/or personal injury.

• Use safety eye protection and any other appropriate safety apparel. The bit replacement process may create flying steel chips or other debris.

Pay attention to all onlookers to remain clear of flying debris. Improper safety procedures may result in property damage and/or personal

injury.

The service life of the auger bits are affected by soil classification, soil moisture content and general operating procedures. A consistent auger

maintenance program provides maximum digging performance.

The replacement of the auger screw bit or blade requires a level working platform of sufficient size and appropriate height.

Idler pulley

Barrel end