APPENDIX

AP-2

2. Cut the main shaft to the necessary length.

• It is recommended to use a machine lathe to shorten the shaft.

• Chamfer the top of the main shaft as shown below. (For chamfering with a file use a fine

file and finish the surface as smooth as possible.)

• When clamping the shaft with a clamp, be careful not to damage the shaft surface.

• When a metal saw is used to shorten the shaft, finish the top of the shaft so that it is level

within 3 mm.

Within 3 mm

C1

R1

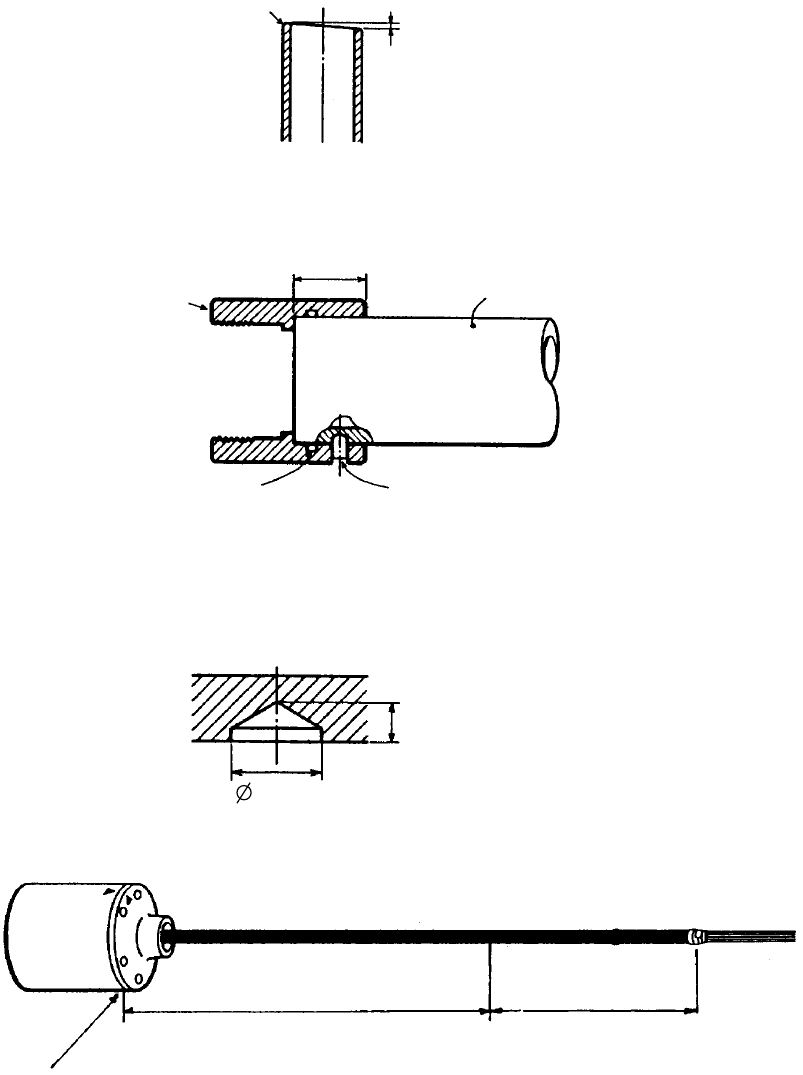

3. Temporarily install the waterproofing attachment on the top of the main shaft and drill

holes for socket-set screws.

Shaft

Waterproofing

attachment

O-ring

M6 socket-set screw

30 mm

Push in fully (O-ring will resist.)

a) Mark drilling point on the shaft surface by tightening M6 socket-set screws (2 pcs.)

b) Remove the waterproofing attachment.

c) Drill holes les than 2 mm in depth. Use a drill with a Ø120 tip°. Do not drill holes through

the shaft. Use a stainless steel, low rpm drill with cutting oil.

Less than 2 mm

5 mm

Cut level.

4. Remove the sheath of the transducer cable and wrap the sheath end with vinyl tape.

Frange bottom

L

Remove sheath.

L = Main shaft length + 120 mm