November 2003 © TOSHIBA TEC 4 - 1 e-STUDIO3511/4511 PREVENTIVE MAINTENANCE

4. PREVENTIVE MAINTENANCE (PM)

4.1 PM Support Mode

4.1.1 General description

The timing for the parts replacement usually depends on the number of output pages / develop counts

after they were replaced before. However, the life span of them changes depending on the general

use of users and the environment in which the equipment is placed. Therefore, it is necessary to

consider not only the number of output pages but also the drive counts when deciding the timing for

the parts replacement in order to utilize the parts and materials effectively.

In addition, the drum rotates 4 times at color modes to transfer the images of 4 colors on the transfer

belt, overlaying one after another. Therefore, the number of output pages is counted as “4” for 1 page

for printing at color mode.

This equipment has the PM support mode, which makes it possible to see the general use of each

part (the number of output pages, develop counts and drive counts) and replacement record and to do

a counter clearing operation more efficiently when replacing.

The replacement record can be printed out in the list printing mode (9S-103).

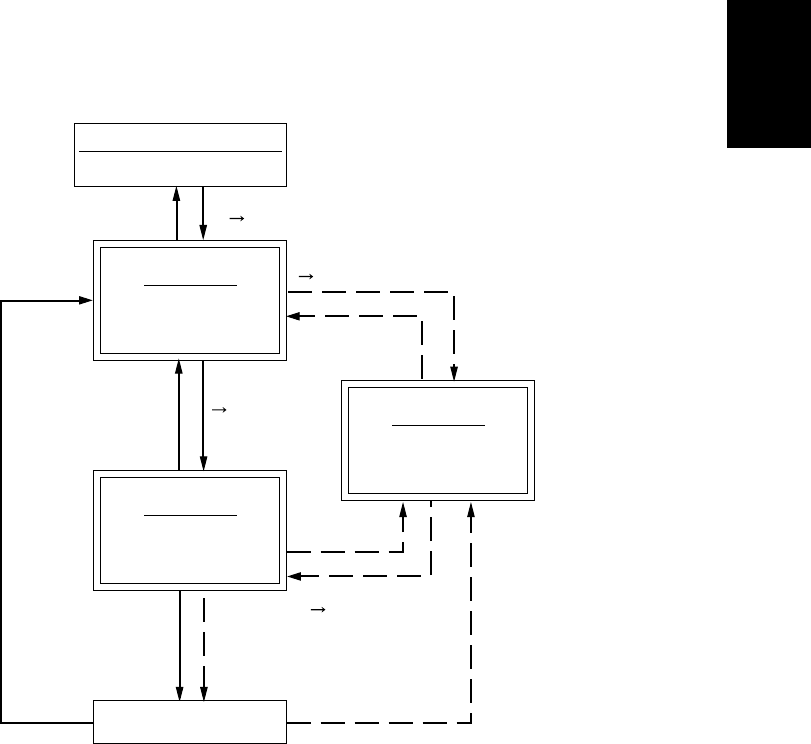

4.1.2 Operational flow and operational screen

(1) Operational flow

* The screen goes back to the main screen when the counter clear is performed or the [CANCEL] button is

pressed after moving from the main screen, while it goes back to the sub screen after moving from the sub

screen.

Fig. 4-101

PM support mode activated

[6]+[START]+[POWER]ON

Main screen

Main unit list displayed

Sub screen

Sub unit list displayed

Clear screen

Counter clear

confirmation displayed

Counter clear performed

[RETURN]

pressed

[CANCEL] pressed

[RETURN] pressed

[CANCEL]

pressed

[INITIALIZE]

pressed

Sub unit chosen

[RESET] pressed

Clear finished

Clear finished

Main unit chosen

[RESET]

Main unit chosen

[SUB UNIT] pressed

[2] [START]