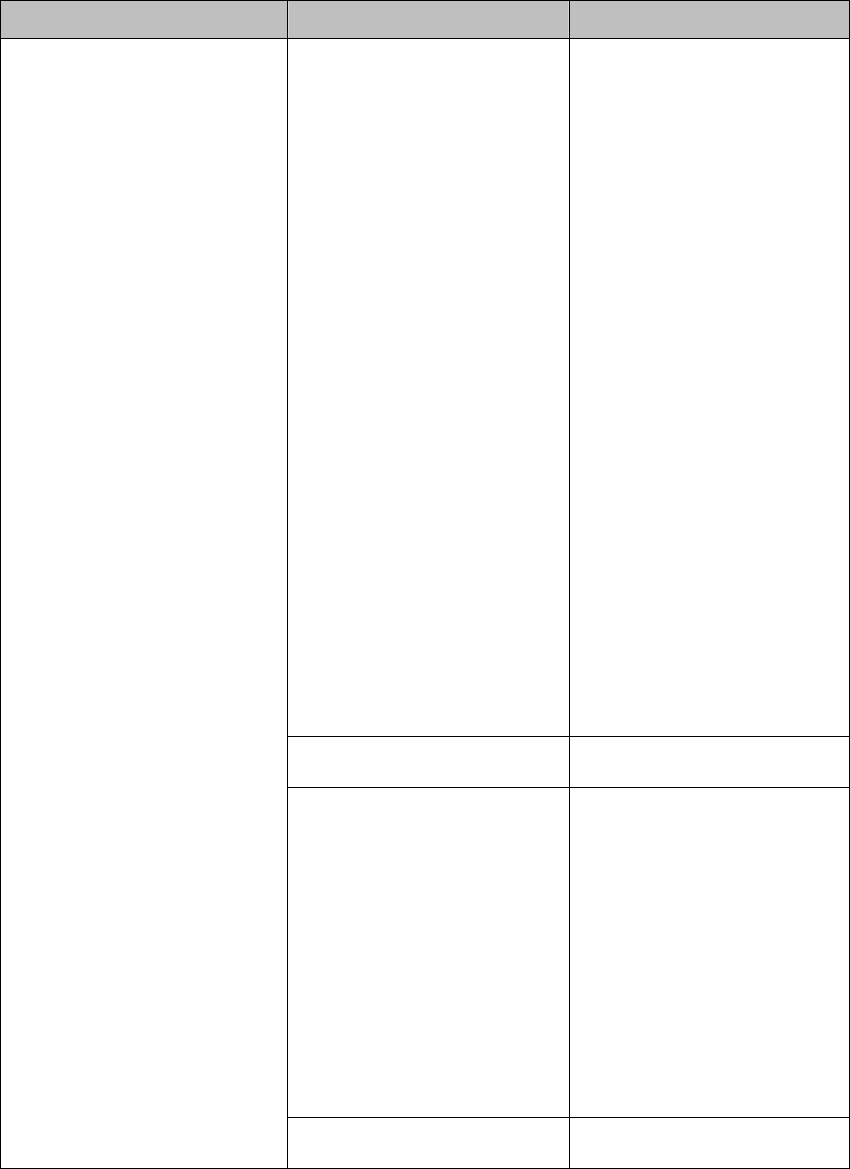

Conveying System Mechanical Components Chapter 6: Troubleshooting 100 of 138

Problem Possible Cause Possible Remedy

Vacuum leak(s) in vacuum

hoppers.

• Replace or re-install worn

or misaligned gaskets.

• Hopper discharge flapper

not sealing under vacuum.

1) Replace worn or

missing gasket.

2) Clean fouled flapper.

3) Check counterweight

for proper operation.

Repair or adjust as

needed.

• Internal check valves

missing or damaged. On

single line Y systems,

internal check valves must

be installed in the vacuum

hoppers to seal all hoppers

not being conveyed to. If

the check valves are

present and undamaged,

they may be pushed too

far onto the tube stub to

permit a proper seal. Also,

if the hopper is over-filled,

the check valve may not

seal properly.

Vacuum leaks in material

lines.

Check for leaks as described

in previous steps.

Material take-offs not

properly adjusted.

Too much air and not

enough material or too much

material and not enough air.

Close takeoff compartment

material inlet, slowly open

until you hear material

surging and slugging. Close

material inlet until surging

disappears. On most

systems, a proper adjustment

generates a 6” to 10” Hg

(203 to 339 millibars)

vacuum.

Vacuum conveying rate is

declining due to a vacuum

loss in the system.

(Cont’d.)

The blower is dead-headed.

Check the blower inlet for

obstruction.