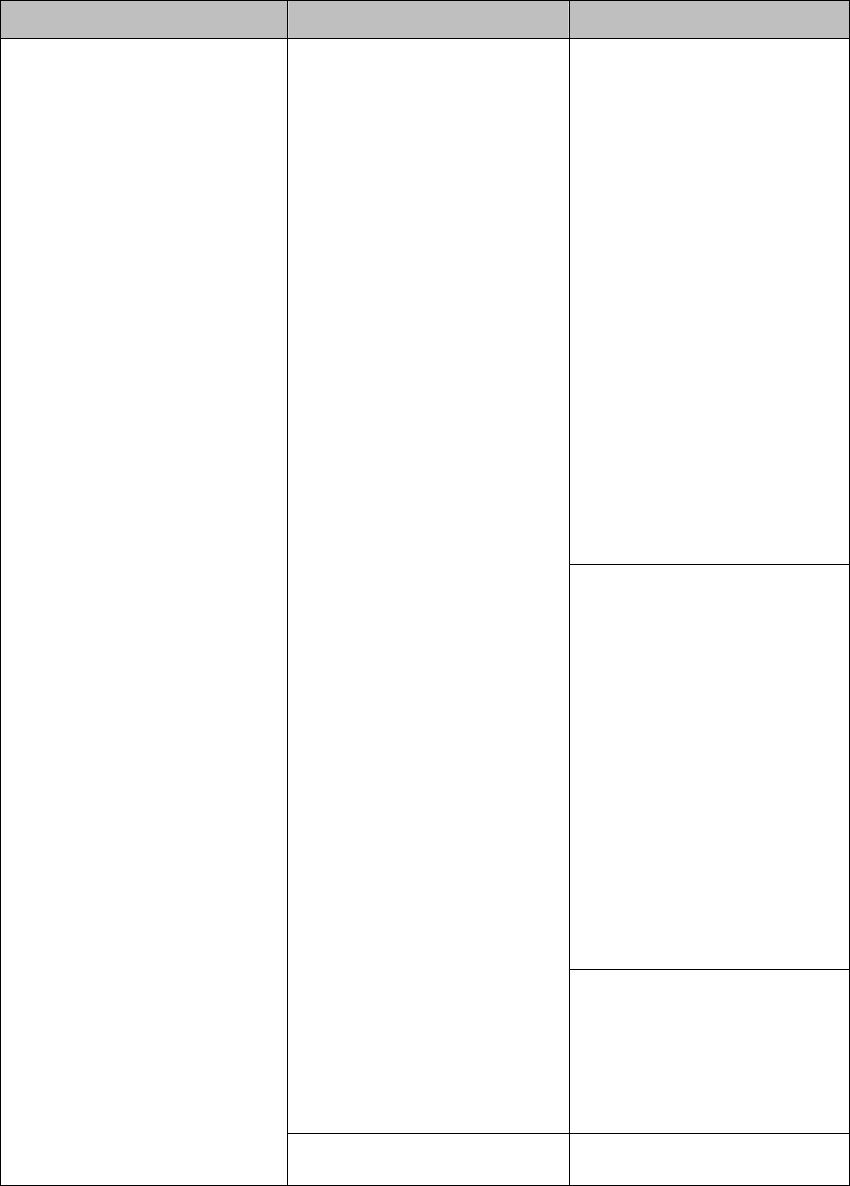

Conveying System Mechanical Components Chapter 6: Troubleshooting 99 of 138

Problem Possible Cause Possible Remedy

Dirty filter. Clean or replace

filter.

• Loose clamps, gaskets or

couplers. Tighten or

replace.

• Filter chamber discharge

flapper not sealing under

vacuum. Check for proper

operation; clean or repair

as needed.

• Check for faulty

compressed air blowback

solenoid. Check for

voltage signal during

cleaning cycle, proper

solenoid operation,

incorrect wiring, proper

compressed air

connection, and for worn

plunger in valve.

Vacuum line problem.

Disconnect the vacuum line

at the first vacuum hopper

and block it off. The vacuum

here should equal the

vacuum at the blower. Allow

a few seconds for vacuum to

build. If the vacuum here is

low, disconnect the piping

halfway to the first vacuum

hopper and check the

vacuum there. If proper

vacuum exists, the problem

is upstream. If not, work

backward to isolate the

vacuum loss.

Pump package blower

problem. Use a cfm/cfh

monitoring device to ensure

that blower cfm/cfh is to the

manufacturer’s

specifications. (Cont’d.)

Consult Service Engineer if

problem persists.

• Tighten loose pipe

couplers; replace worn

gaskets as needed.

• Replace any damaged

piping found.

Vacuum conveying rate is

declining due to a vacuum

loss in the system.

(Cont’d.)

Leaks in vacuum lines

between valves.

Check for leaks as described

in previous steps.