Conveying System Mechanical Components Chapter 3: Installation 49 of 138

• You can attach a quick-change or standard tube coupler to vinyl flex hose by inserting

a stub of hard tube into the hose and securing it with a hose clamp. Be sure enough

tube extends from the hose to properly install the quick-change or coupler. Make sure

that you put clear silicone caulk around adjoining tube seams for exterior bolted

couplers.

• If you use stainless flexible material hose, the material flow must be in the direction as

indicated by the arrows on the hose. Material direction is not critical with vinyl flex

hose.

• Bring all truck fill lines to a central location, such as a silo, unless otherwise specified.

• All rail car manifold Y-tubes must be installed with a ten-degree (10º) downward slant

from horizontal on the leg section. Make sure that space between rail car manifold

Y-tubes are fifteen feet (15’/4.5 meters) on center to allow proper alignment between

rail car discharge ports and the manifold Y-tubes.

• A plug must be put in the last sequence T valve on the vacuum header to prevent

vacuum loss. If atmospheric valves are used, you must terminate the vacuum line at the

last atmospheric valve.

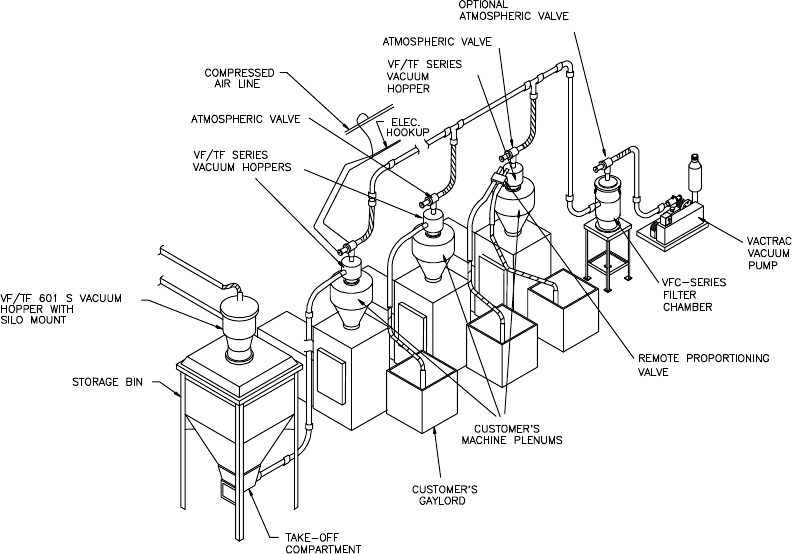

Multiple Line System Piping Considerations

• Multiple line systems have separate material lines for each material to allow different

types of materials to be conveyed.

• Multiple line systems have separate pickup devices for each vacuum hopper.

• Materials are often loaded from beside the processing machine from gaylords, grinder

takeoffs, and storage bin takeoffs.

Figure 22: Typical Multiple Line System Installation