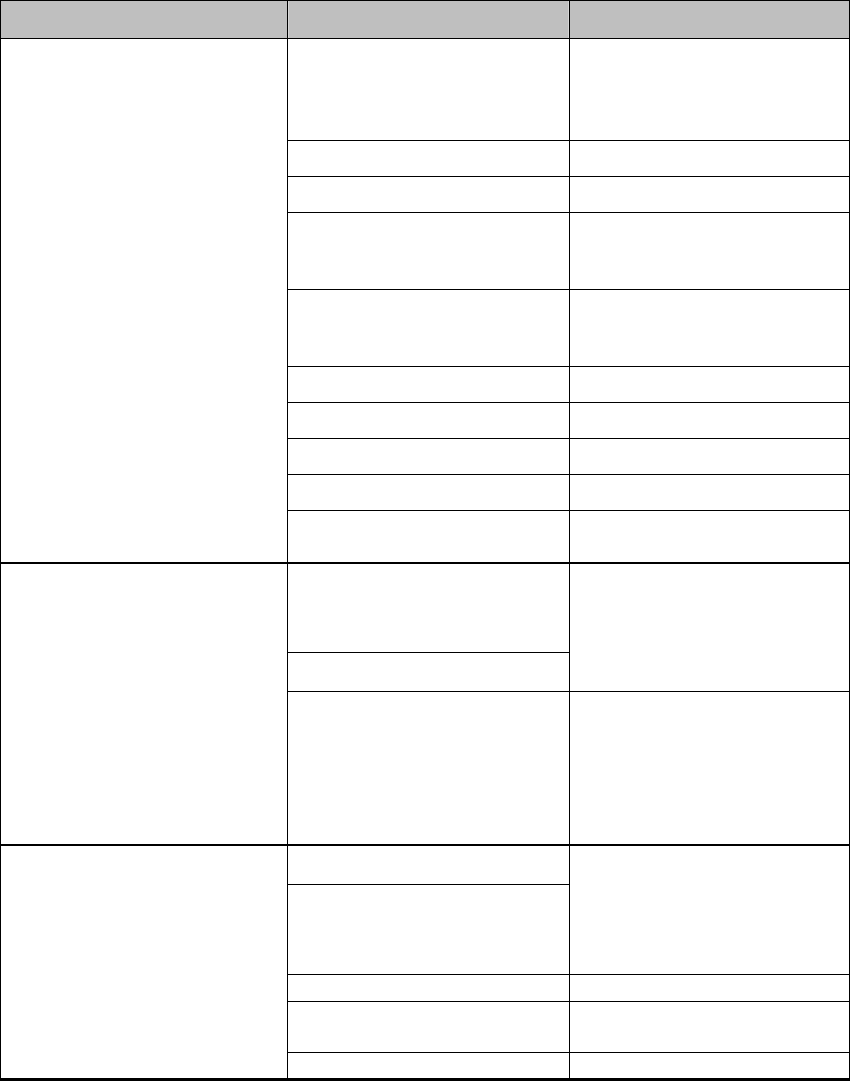

Conveying System Mechanical Components Chapter 6: Troubleshooting 96 of 138

Problem Possible Cause Possible Remedy

Material or vacuum line

plugged.

Find and remove the

obstruction, such as a

coupling gasket and gaylord

bags.

Filter chamber filter dirty. Clean filter.

Vacuum hopper filter dirty. Clean filter.

Bad atmospheric/sequence-T

valve.

Check for signal, sufficient

compressed air, proper

wiring and operation.

Vent valve on pump package

not operating correctly.

Check for signal, sufficient

compressed air, proper

wiring and operation.

Improper piping. Locate and correct.

Convey time set too long. Reduce convey time.

Collapsing hoses. Inspect hoses.

Faulty vacuum switch. Test – ON – replace switch.

High-Vacuum alarm.

Take off compartment

closed.

Adjust take-off box.

Conveying times are too

long (Time Fill only).

Special convey enabled.

Observe and time the

hopper(s) when loading.

Note the time needed to fill a

hopper. Set the conveying

time to a few seconds less.

Vacuum receivers are being

overfilled.

(Refer to enclosed Control

Panel Manual)

Maximum conveying times

are too long (Volume Fill

only) and the Receiver Full

proximity switch(es) are not

being recognized by the

PLC.

Check proximity sensors for

proper operation and proper

wiring to PLC. Repair. Re-

set the conveying times to

reasonable times. Re-adjust

if needed; see Page 76.

Poor take-off adjustment.

Conveying times are too

short (Time Fill only). (See

control panel’s O & I.)

Observe and time the

hopper(s) when loading.

Note the time needed to fill a

hopper. Set the conveying

time to a few seconds more.

Vacuum line leak. Find and repair leak.

No material to convey.

Make sure pickup probe is

buried in material source.

Vacuum receivers are being

under-filled.

Vacuum filter is plugged. Clean and/or replace filter.