Conveying System Mechanical Components Chapter 3: Installation 54 of 138

Note: Use of a system without an approved filter system

installed on the vacuum air inlet voids the blower warranty!

Installing the Filter Chamber Shroud

The cloth filter shroud is mounted to a ring on the underside of the filter chamber stand. It

reduces housekeeping duties around the filter chamber by preventing dust from becoming

airborne when the dust and fines are discharged from the SFC filter chamber. The dust

container below the shroud is customer-supplied—the standard 24” (61 cm) clearance stand

is designed for use with a 5-gallon (19-liter) pail, and the optional 38” (96 cm) clearance

stand is designed for use with a 55-gallon (208-liter) drum.

1. Insert the filter shroud support wire into the slotted hole in the middle of the cloth

filter shroud. Use supplied hardware to secure.

2. Slip the filter shroud over the retaining ring located on the bottom side of the filter

stand mounting plate. Secure it with the worm clamp provided.

3. Place the dust container you’ve supplied below the filter chamber stand and insert the

filter shroud.

4. On standard 5-gallon (19-liter) pails, the filter shroud should be trimmed and fastened

to the top lip of the can with a band clamp. Don’t trim the filter shroud on 55-gallon

(208-liter) drums. Secure the drawstring on the shroud around the drum, making sure

the open end of the shroud hangs freely inside the drum.

5. Make sure the operation of the counterweighted flapper dump valve is not obstructed

in any way by the filter shroud. See Figure 21 on page 47 for a typical example of a

filter chamber shroud.

Caution! Do not obstruct the filter shroud in any way. Empty the dust container

before the dust level obstructs the end of the filter shroud.

Failure to observe these directives may result in reduced filtering efficiency

and contaminants entering the conveying system.

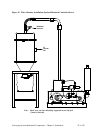

Installing ACA Series Filter Chambers

Powders or granular materials with fines can cling to filters and contaminate operating

components. The ACA Series filter chamber is a self-cleaning filtration unit that enables such

materials to be conveyed.

During material conveying, fines accumulate on the outside of the filter media as the air

passes through a filter bag. These fines must be periodically removed to prevent performance

losses in the conveying system. The ACA Series filter utilizes a plant-based compressed air

supply to clean filter bags with intermittent air pulses.

At preset time intervals, a solenoid valve activates, interrupting continuous compressed air

flow to the unit. This interruption causes an exhaust valve to open, allowing stored

compressed air from an accumulator to be released down inside the filter bag. This

momentary burst of air stops the flow of dust-laden air through the filter bag and flexes the

filter fabric. This, along with the reverse flow of air, causes the accumulated dust to fall off

the bag and back into the hopper for discharge.

This instantaneous cleaning action of air pulses are directed to each individual filter bag in

sequence and at a specified duration. You can adjust the time between air pulses; different

conveying rates and materials require different air pulse times. Air pulses must occur more