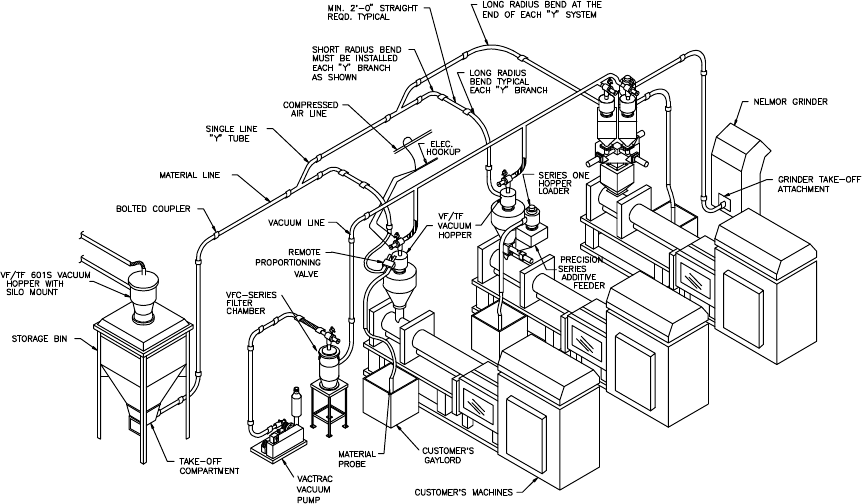

Conveying System Mechanical Components Chapter 3: Installation 52 of 138

Figure 26: Typical Single Line Y-Tube System Installation

Material Check Valves in Single Line Y-Tube Systems

• Check valves are a critical feature on single line Y systems. You must have a check

valve installed on the material inlet inside the receiver on all vacuum hoppers in single

line Y installations.

• Check valves must open when the receiver is being loaded and seal to prevent a

vacuum leak when other hoppers are being loaded.

• Vacuum receivers for these systems have a special factory-installed extended material

inlet tube to hold the check valve.

• The check valve must not be pressed too far onto the inlet stub to prevent proper

sealing.

• The hinge of the check valve should be up to prevent material from being deflected up

into the vacuum hopper filter.

• Do not allow vacuum receivers with check valves to be over-filled to a point above the

bottom of the check valve. Over-filling prevents the check valve from sealing and

creates a vacuum loss. Adjust the conveying time on Time-Fill systems to prevent this

from happening.

• Inspect periodically for erosion or wear. Replace as required.