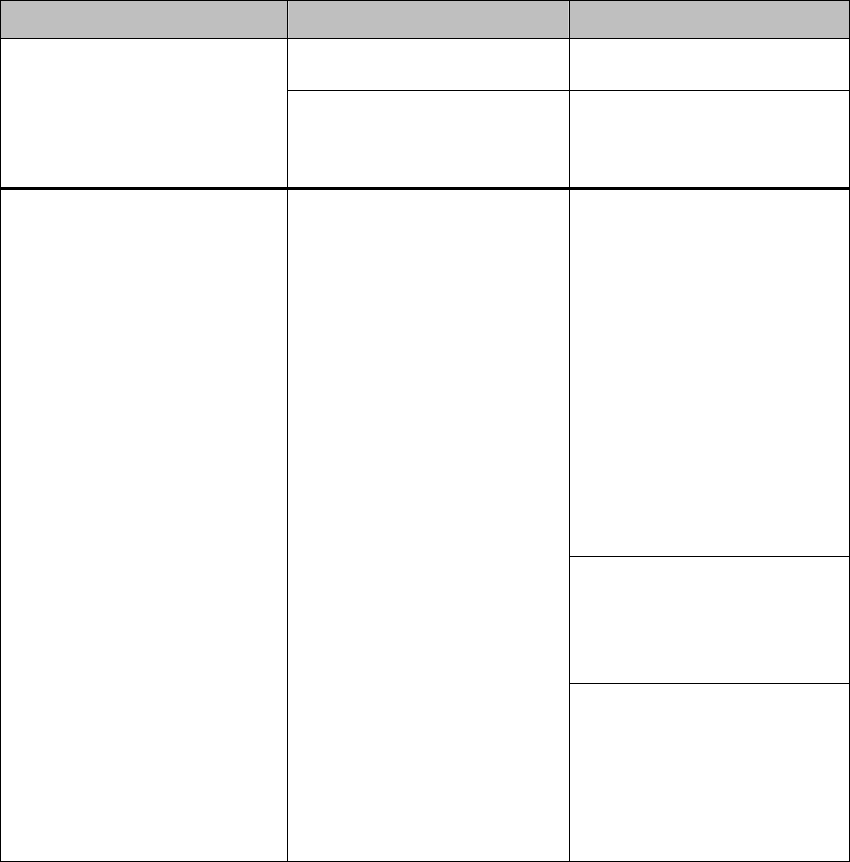

Conveying System Mechanical Components Chapter 6: Troubleshooting 98 of 138

Problem Possible Cause Possible Remedy

The alarm package is wired

incorrectly.

Correct wiring. Consult

wiring diagram.

Optional audible alarm is not

functioning.

(Refer to enclosed Control

Panel Manual for specific

instructions.)

Alarm package component

failure.

Troubleshoot and

repair/replace problem.

• Blower is dead-headed.

Check for obstruction.

• Vent valve is not

operating. Check for

proper signal, voltage, and

80 to 90 psi (552 to 621

kPa) compressed air.

• Worn seals in blower.

Rebuild/replace blower.

• Worn bearings in blower.

Rebuild or replace.

• Loose drive belt(s).

Tighten or replace if worn.

Follow the vacuum path

from the blower through the

filter, piping, valves and

material receivers to isolate

where the loss occurs.

Vacuum conveying rate is

declining due to a vacuum

loss in the system.

Pump package blower

problem. Use a cfm/cfh

monitoring device to ensure

that blower cfm/cfh is to the

manufacturer’s

specifications.

Consult Service Engineer if

problem persists.

Filter chamber problem. The

vacuum at the filter chamber

should be the same as the

blower generates. If the

vacuum at the filter chamber

is adequate, the problem is

down line.