Conveying System Mechanical Components Chapter 3: Installation 48 of 138

Installing the Control Panel

Select a flat, vertical area for mounting the panel. It should be in an area that gives your

operator access to the control. Consider how you are running wiring to the vacuum hoppers,

the filter chamber, and pump motor starter(s), vacuum switch(s), and vent valve(s). The panel

requires a low voltage grounded power drop as listed on the serial tag.

Note: Avoid mounting control panel near material lines.

Installing Material/Vacuum Tubing

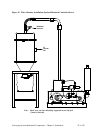

Well-designed material/vacuum piping systems provide the best conveying rates.

Vacuum/material piping may be a single material line Y system or a multiple material line or

a combination of the two systems, depending on the processing floor layout. All systems

utilize a common vacuum header line for all stations connected to a pump package; material

flow is controlled by sequence T or atmospheric valves operated by the control panel. When

installing material/vacuum tubing, take the following into consideration:

• Vacuum leaks anywhere in the system reduce system capacity.

• Keep the number of material tube bends, elbows, Y-tubes, and vacuum T-tubes to a

minimum for maximum system capacity.

• Use long radius tube bends on material lines.

• Keep the total length of material conveying flex hose to a minimum. Long flex hose

material runs reduce system capacity.

• Vertical material tubing runs should be straight up. Inclined runs can reduce capacity.

• Support tubing about every ten feet with straps, pipe hangers, or brackets.

• Tube joints must be rigid to prevent vacuum or material leaks.

• Cut tube ends square and chamfer edges smooth. Use a fixed band saw or power miter

saw when making cuts. You can use a tubing cutter on aluminum tubing, but you need

to use a saw with a carbide or diamond-impregnated saw blade when cutting stainless

steel. Chamfer outer and inner edge cuts with a die grinder or a hardened rasp file.

• Clean all tubing after cutting and before assembly. Dampen a rag in a non-volatile

cleaning solvent, and run it through all tubing and couplers to remove sediment from

shipping or cutting. Run a quantity of low-grade material through new lines to remove

any remaining sediment, and then discard the material immediately.

• Tube ends must butt together inside couplers.

• Tighten tube coupler nuts from the center outward to ensure a tight seal and allow

proper contact of the internal grounding strip.

• Each material tubing run must maintain an electrical continuity through the tubing and

couplers, from pickup point to vacuum hopper. Grounded flexible hose is

recommended.

• If you must cut bends, cut the straight section, leaving enough straight length for

complete insertion into a coupler.