Conveying System Mechanical Components Chapter 3: Installation 64 of 138

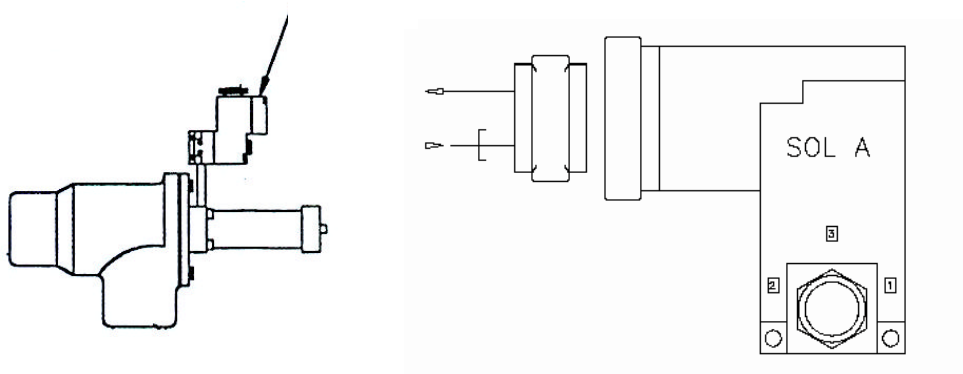

Figure 31: Solenoid Valve Location on Atmospheric Valve & Compressed Air Connections

(1) Normally Closed Port = Connect to Air Supply

(2) Common = Connect to Valve

(3) Normally Open = Exhaust Port

Your

3

/8” (9 mm) branch supply line should include:

1. A shutoff valve for ON/OFF control.

2. An air filter/pressure regulator with a gauge for pressure control.

3. Mini-lubricators located at each vacuum receiver.

Install a quick-disconnect fitting or a shutoff valve in the compressed air piping leading to the

vacuum receiver atmospheric valve to speed receiver cover removal for cleanout or service.

Connecting Vacuum Receivers with Sequence-T Valve Compressed Air Lines

See Figure 32 on the following page for an illustration of a typical sequence-T valve. Critical

dried resin systems sometimes require sequence-T valves to prevent drawing humid atmo-

spheric air into the material supply. Sequence-T valves are usually installed in the vacuum

header above the vacuum hoppers.

Note: The sequencing valve is located in the cover on SR Series vacuum receivers if

you selected the internal sequencing valve option.

If mounted in the vacuum line, connect the sequence-T valve to a 60 psi to 80 psi (414 kPa to

552 kPa) source of clean, dry, lubricated compressed air.

Run a

3

/8” (9 mm) branch line off the plant air main to the sequence T valves in your system.

Install a

3

/8” (9 mm) x

1

/8” (3 mm) tee in the up position near each receiver.

Connect compressed air to the normally open port on top of the sequence-T valve solenoid

valve with a

1

/8” (approx. 3 mm) pipe nipple. Connect the common port to the sequence-T

valve using

1

/4” (6 mm) poly tube and connectors. See the following for more information.

Solenoid Valve