18 WSHP-PRC001-EN

Tracer ZN510 & ZN524 Controls

The Tracer ZN510 and ZN524 are di-

rect digital control (DDC) systems spe-

cifically designed for single and dual

circuited water-source equipment to

provide control of the entire unit, as

well as outputs for unit status and fault

detection. Each de-

vice is factory in-

stalled,

commissioned,

and tested to en-

sure the highest

level of quality in

unit design.

Each of the con-

troller’s features

and options were

selected to coordi-

nate with the unit

hardware to pro-

vide greater ener-

gy efficiency and

equipment safety

to prolong the

equipment life.

In addition to be-

ing factory config-

ured for control of

the unit fan, compressor and reversing

valve, the ZN510 and ZN524 control-

lers are designed to coordinate the wa-

terside of the water-source system

through the Tracer Loop Controller

(TLC). If applied in a peer-to-peer com-

munication environment, data be-

tween similar controllers may be

exchanged without requiring a build-

ing automation system.

By teaming the ZN510 and ZN524 with

the TLC, a low first-cost for the me-

chanical equipment, water loop, and

water pump optimization is provided

to the owner.

For owners who require a full building

integrated "open protocol" system,

The ZN510/ZN524/TLC application is

upgradable to support complete build-

ing control through Tracer Summit.

Because the ZN510 and ZN524 is Lon-

Talk certified, it is capable of working

with, and talking to other LonTalk cer-

tified controllers providing the build-

ing owner more choices, and the

design engineers more flexibility to

meet the challenges of building auto-

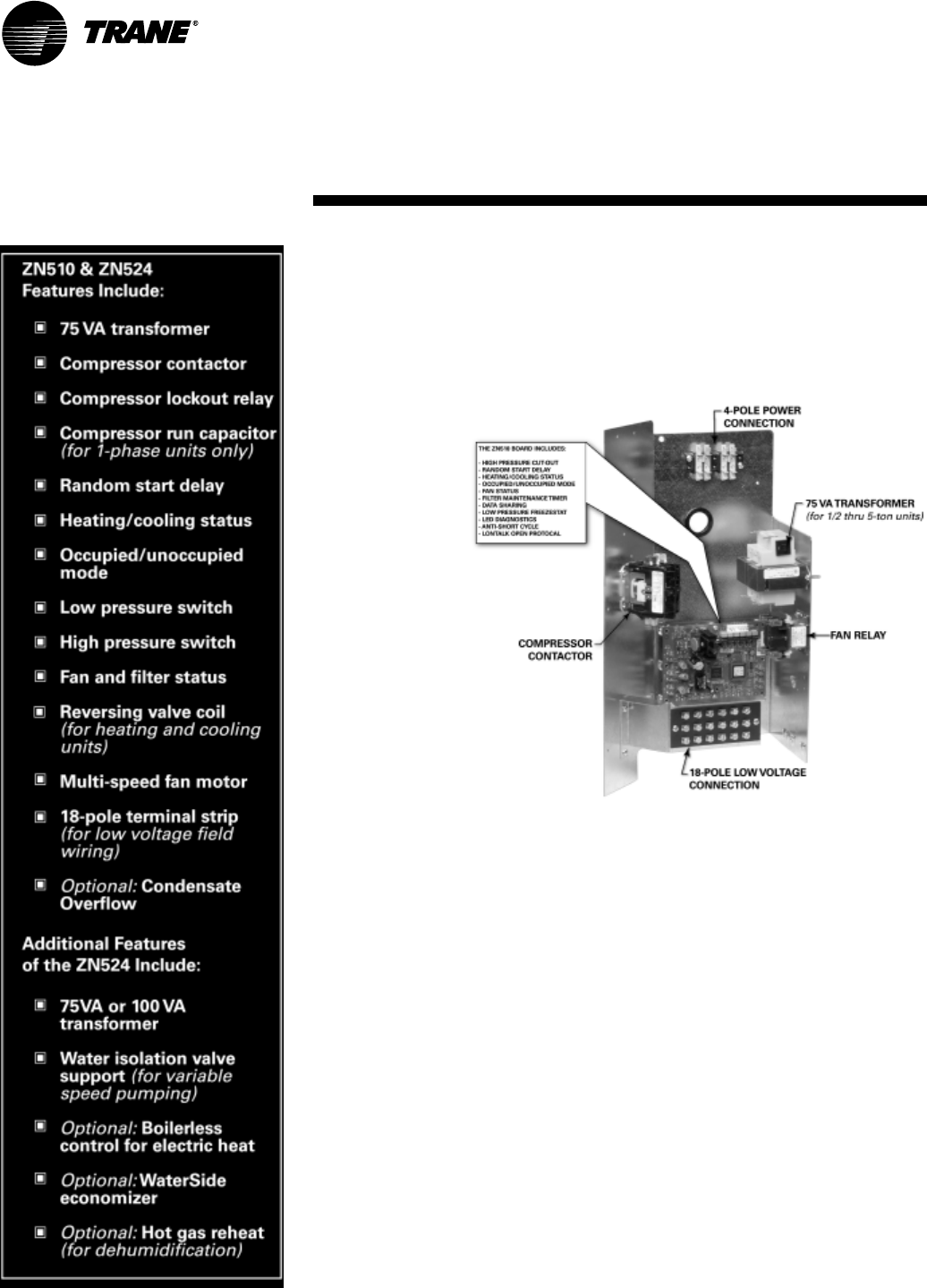

mation. See Figure 28 for ZN510 con-

trol box.

Features and Benefits

ZN510 & ZN524 Controls

Figure 28: ZN510 control box