WSHP-PRC001-EN 23

Central Pumping System

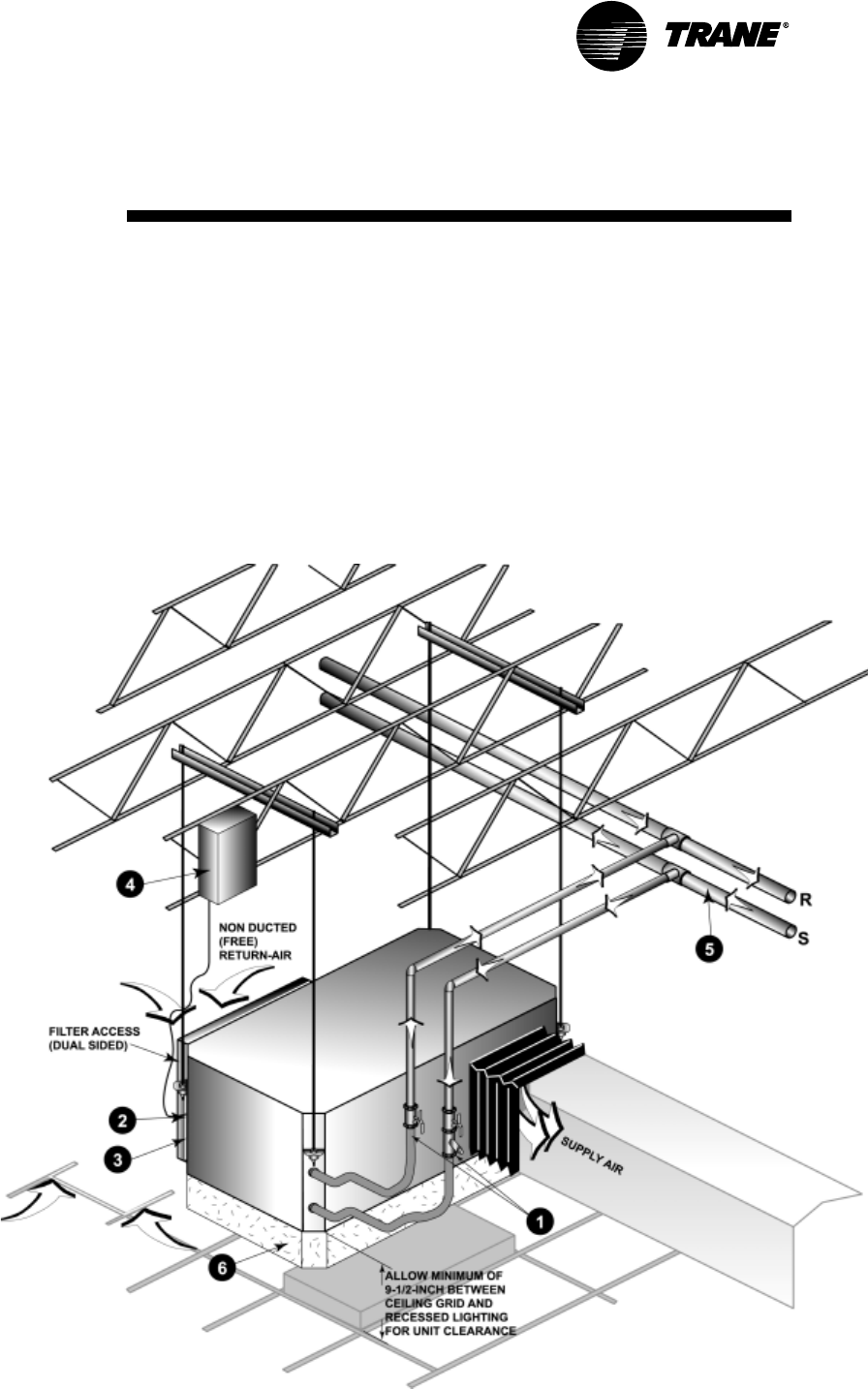

Units that employ a central pumping

system contain single or dual pumps

to fulfill pumping requirements for the

entire building system.

The central system’s supply and re-

turn lines should be sized to handle

the required flow with a minimum

pressure drop.

The water-source heat pump (in this

case a high efficiency GEH) may in-

clude add-on accessories to help aid in

system balancing, acoustics and safe-

ty requirements. Some of these items

may be ordered from the factory, then

field installed. Many are provided by

the contractor.

Hose kits are used to connect the

water supply and return line to the

water inlets and outlets. Trane of-

fers various hose kit combinations

to better facilitate system flow

balancing. These flexible

hoses also aid in the reduc-

tion of vibration between the

unit and the rigid central pip-

ing system.

A two position isolation valve is

often applied to systems which in-

corporate variable frequency

pumping. This valve is capable of

stopping/starting water flow to the

unit, which in-turn reduces the

pumping requirements for

the entire system.

The unit’s (item 2) 3/4-inch

high voltage and (item 3) 1/2-inch

low voltage connections are locat-

ed on the left chamfered corner

of the unit. They are de-

signed to accept con-

duit.

A field supplied line voltage dis-

connect should be installed for

branch circuit protection. Check

local codes for requirements.

The central system supply and re-

turn lines should be sized to han-

dle the required flow with a

minimum pressure drop.

Note: Pipe will sweat if low tem-

perature water is below the dew

point of the surrounding space.

Trane recommends that these

lines be insulated to prevent dam-

age from condensation when con-

denser loop is designed to be

below 60 F. Equipment installed in

attic/crawl space temperatures be-

low 40°F may require antifreeze in

the water loop.

For acoustically sensitive areas, a

six-inch deep fiberglass insulation

is recommended to be field in-

stalled below the horizontal unit.

This field supplied insulation

should be approximately twice the

footprint size of the unit. It pro-

vides sound damping of the unit

while in operation.

Application

Considerations

1

2

3

4

6

5