24 WSHP-PRC001-EN

Distributed Pumping System

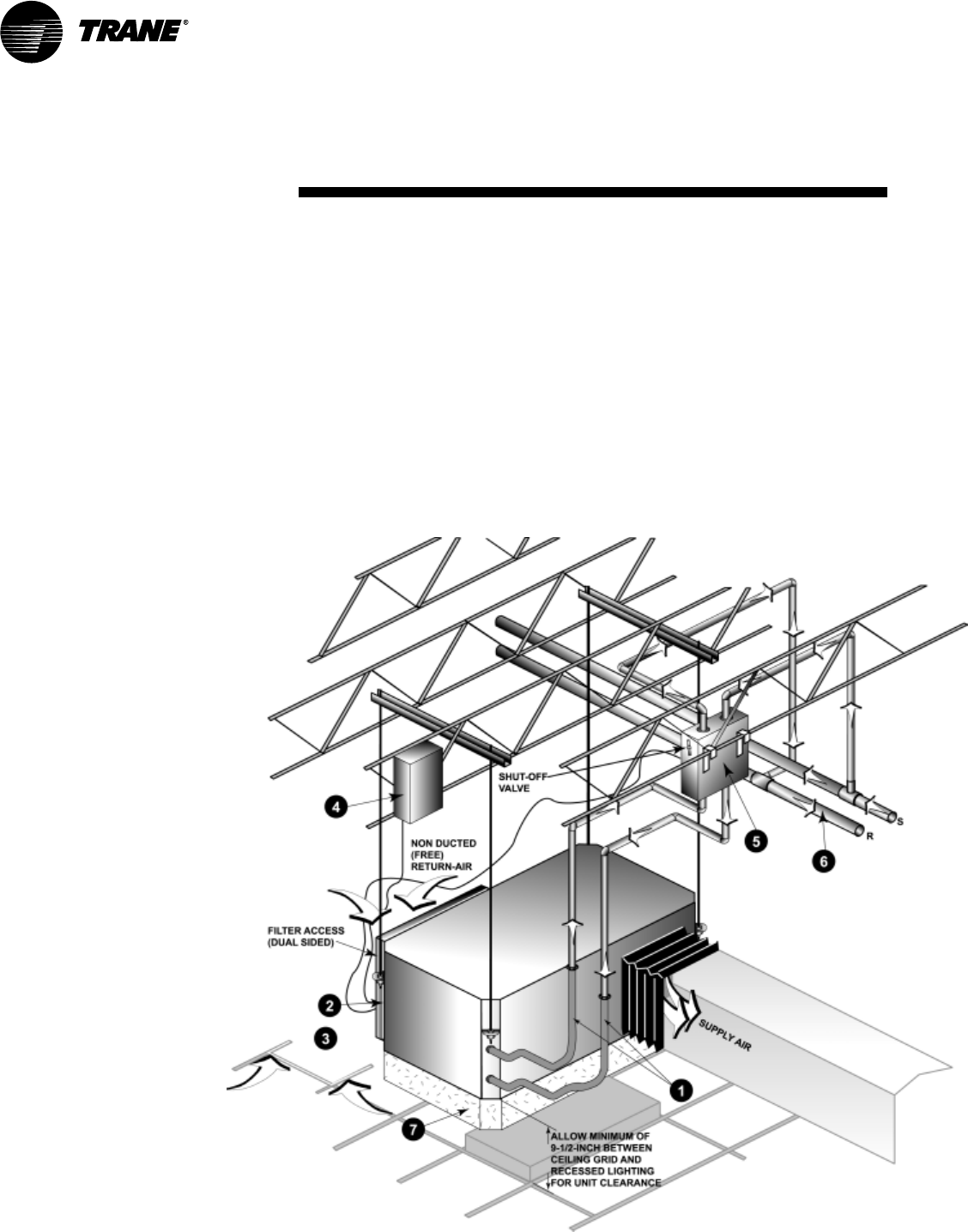

A distributed pumping system con-

tains either a single or dual pump

module, specifically sized for each wa-

ter-source heat pump, then connected

directly to the units supply and return

lines.

The distributed system’s supply and

return lines should be sized to handle

the required flow with a minimum

pressure drop.

Hose kits are used to connect the

water supply and return line to the

water inlets and outlets. Trane of-

fers various hose kit combinations

to better facilitate system flow bal-

ancing. These flexible hoses also

aid in the reduction of vibration be-

tween the unit and the rigid central

piping system.

The unit’s (item 2) 3/4-inch high

voltage and (item 3) 1/2-inch low

voltage connections are located

on the left chamfered corner of

the unit. They are designed to ac-

cept conduit.

A field supplied line voltage dis-

connect should be installed for

branch circuit protection. Check lo-

cal codes for requirements.

Trane’s self-contained pump mod-

ule and hose kit make a com-

plete pumping package for

distributed pumping systems.

The module is designed for circu-

lating commercial loops that re-

quire a maximum flow rate of 20

gpm. Each pump module is ful-

ly assembled for connec-

tion to water and electrical

points. The kit contains all

of the necessary compo-

nents for the installation, operation

and maintenance of a closed loop

application. See WSHPC-IN-5

(72-9006-03) for electrical and di-

mensional requirements

The distributed pumping system

supply and return lines should be

sized to handle the required flow

with a minimum pressure drop.

Note: Pipe will sweat if low tem-

perature water is below the dew

point of the surrounding space.

Trane recommends that these

lines be insulated to prevent dam-

age from condensation when con-

denser loop is designed to be

below 60 F. Equipment installed in

attic/crawl space temperatures be-

low 40°F may require antifreeze in

the water loop.

For acoustically sensitive areas, a

six-inch deep fiberglass insulation

is recommended to be field in-

stalled below the horizontal unit.

This field supplied insulation

should be approximately twice the

footprint size of the unit. It pro-

vides sound damping of the unit

while in operation.

Application

Considerations

1

2

3

4

5

67