148

Motor noise, EMI measures, mechanical resonance

4.15 Motor noise, EMI measures, mechanical resonance

4.15.1 PWM carrier frequency and Soft-PWM control (Pr. 72, Pr. 240, Pr. 260)

(1) PWM carrier frequency changing (Pr. 72)

You can change the PWM carrier frequency of the inverter.

Changing the PWM carrier frequency produces an effect on avoiding the resonance frequency of a mechanical system or

motor or on EMI measures or on leakage current reduction caused by the PWM switching.

(2) Soft-PWM control (Pr. 240)

Soft-PWM control is a control method that changes the motor noise from a metallic tone into an unoffending complex tone.

(3) PWM carrier frequency automatic reduction function (Pr. 260)

When Pr. 260 = "0" (initial value), the carrier frequency becomes constant (Pr. 72 setting) independently of the load,

making the motor sound uniform.

When continuous operation is performed at 85% or more of the inverter rated current with the carrier frequency of the

inverter set to 3kHz or more (Pr.72 ≥ "3") while Pr.260 = "1", the carrier frequency is automatically reduced to 2kHz to avoid

E.THT (inverter overload shutoff). (Motor noise increases, but it is not a failure.)

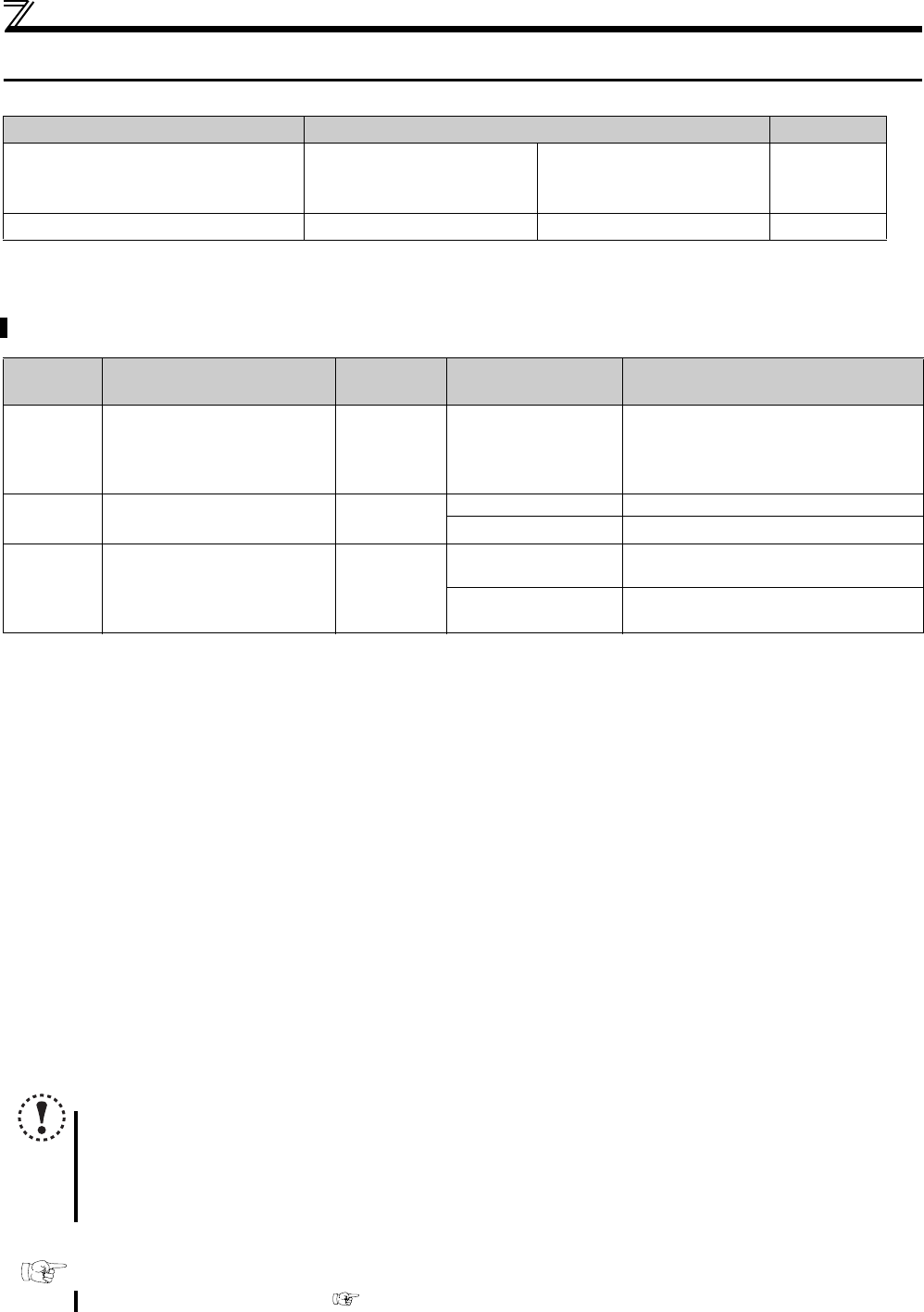

Purpose of Use Parameter that should be Set Refer to Page

Reduction of the motor noise

Measures against EMI and leakage

currents

Carrier frequency and

Soft-PWM selection

Pr. 72, Pr. 240, Pr. 260 148

Reduce mechanical resonance Speed smoothing control Pr. 653 149

You can change the motor sound.

Parameter

Number

Name Initial Value Setting Range Description

72 * PWM frequency selection

1 0 to 15

You can change the PWM carrier frequency.

The setting is in [kHz].

Note that 0 indicates 0.7kHz and 15

indicates 14.5kHz.

240 *

Soft-PWM operation

selection

1

0 Soft-PWM is invalid

1 When Pr. 72 = "0 to 5", Soft-PWM is valid.

260

PWM frequency

automatic switchover

0

0

PWM carrier frequency is constant

independently of load.

1

Decreases PWM carrier frequency

automatically when load increases.

The above parameters can be set when Pr.160 Extended function display selection = "0". (Refer to page 162)

* The parameters in the table allow its setting to be changed during operation even if "0" (initial value) is set in Pr. 77 Parameter write selection.

NOTE

Decreasing the PWM carrier frequency affects on EMI measures and on leakage current reduction, but increases

motor noise.

When PWM carrier frequency is set to 1kHz or less (Pr.72 ≤ 1), fast response current limit may function prior to stall

prevention operation due to increase in ripple currents, resulting in insufficient torque. In such case, set fast-

response current limit operation invalid using Pr. 156 Stall prevention operation selection .

Parameters referred to

Pr. 156 Stall prevention operation selection Refer to page 79