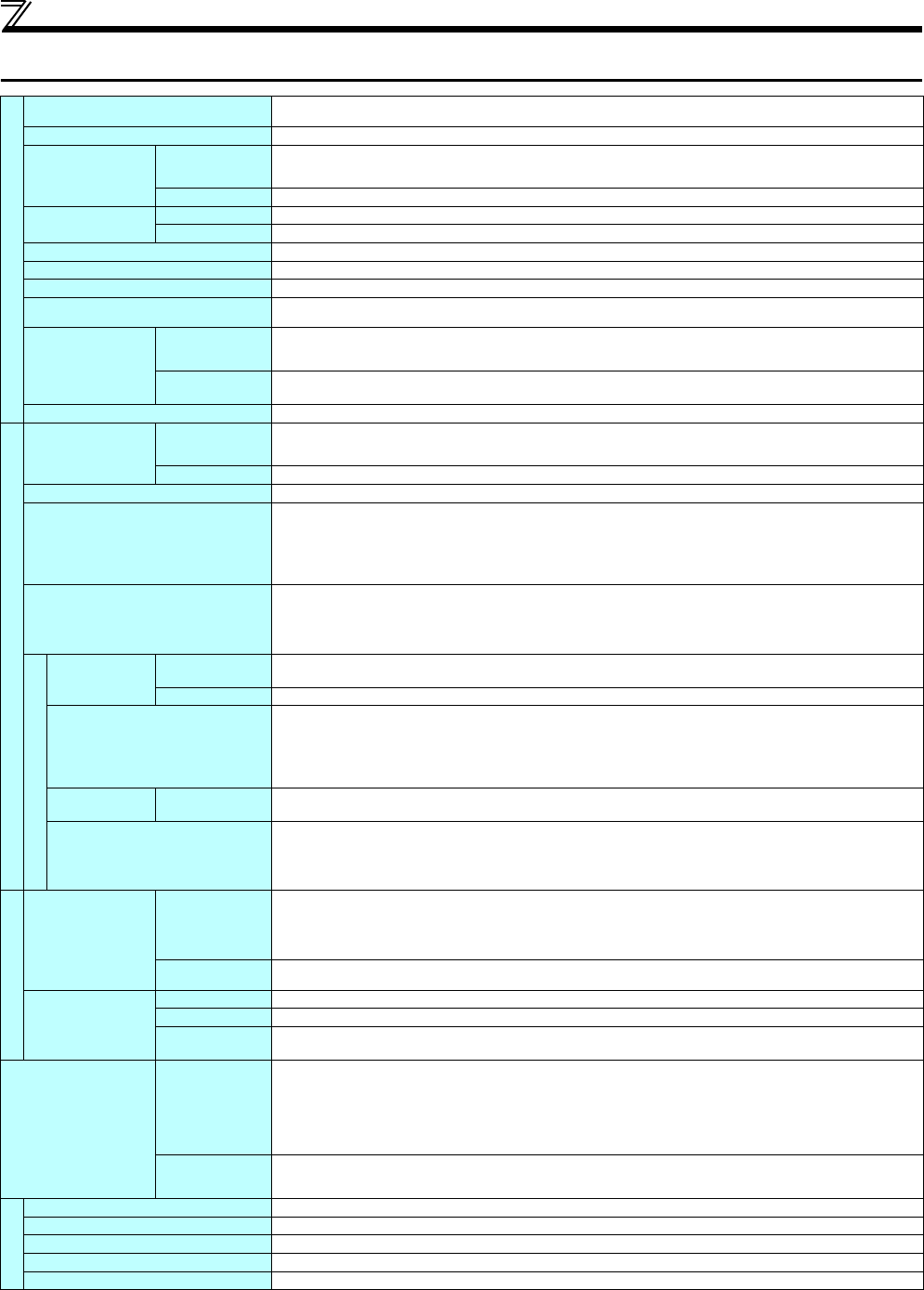

280

Common specifications

7.2 Common specifications

Control specifications

Control method

Soft-PWM control/high carrier frequency PWM control (V/F control, General-purpose magnetic flux vector control,

Optimum excitation control can be selected)

Output frequency range

0.2 to 400Hz

Frequency setting

resolution

Analog input

0.06Hz/60Hz (terminal2, 4: 0 to 10V/10bit)

0.12Hz/60Hz (terminal2, 4: 0 to 5V/9bit)

0.06Hz/60Hz (terminal4: 0 to 20mA/10bit)

Digital input

0.01Hz

Frequency

accuracy

Analog input

Within ±1% of the max. output frequency (25°C ±10°C)

Digital input

Within 0.01% of the set output frequency

Voltage/frequency characteristics

Base frequency can be set from 0 to 400Hz. Constant torque/variable torque pattern can be selected

Starting torque

150% or more (at 1Hz)...when General-purpose magnetic flux vector control and slip compensation is set

Torque boost

Manual torque boost

Acceleration/deceleration time setting

0.1 to 3600s (acceleration and deceleration can be set individually), linear or S-pattern acceleration/deceleration

mode can be selected.

Braking torque

Regenerative∗1

FR-D720-008 and 014, FR-D720S-008 and 014 ... 150%, FR-D720-025 and 042, FR-D740-012 and 022, FR-

D720S-025 and 042 ... 100%, FR-D720-070, FR-D740-036, FR-D720S-070 ... 50%, FR-D720-100 or more, FR-

D740-050 or more, FR-D720S-100 ... 20%

DC injection

brake

Operation frequency (0 to 120Hz), operation time (0 to 10s), operation voltage (0 to 30%) variable

Stall prevention operation level

Operation current level can be set (0 to 200% adjustable), whether to use the function or not can be selected

Operation specifications

Frequency setting

signal

Analog input

Two points

Terminal 2: 0 to 10V, 0 to 5V can be selected

Terminal 4: 0 to 10V, 0 to 5V, 4 to 20mA can be selected

Digital input

Entered from operation panel and parameter unit. Frequency setting increments is selectable

Start signal

Forward and reverse rotation or start signal automatic self-holding input (3-wire input) can be selected.

Input signal

Five points

You can select from among multi-speed selection, remote setting, second function selection, terminal 4 input

selection, JOG operation selection, PID control valid terminal, external thermal input, PU-external operation

switchover, V/F switchover, output stop, start self-holding selection, forward rotation, reverse rotation command,

inverter reset, PU-NET operation switchover, external-NET operation switchover, command source switchover,

inverter operation enable signal, and PU operation external interlock

Operational functions

Maximum/minimum frequency setting, frequency jump operation, external thermal relay input selection, automatic

restart after instantaneous power failure operation, forward/reverse rotation prevention, remote setting, second

function, multi-speed operation, regeneration avoidance, slip compensation, operation mode selection, offline

auto tuning function, PID control, computer link operation (RS-485), Optimum excitation control, power failure

stop, speed smoothing control, Modbus-RTU

Output signal

Output signal

points

Open collector

output

One point

Relay output

One point

Operating status

You can select from among inverter operation, up-to-frequency, overload alarm, output frequency detection,

regenerative brake prealarm, electronic thermal relay function prealarm, inverter operation ready, output current

detection, zero current detection, PID lower limit, PID upper limit, PID forward/reverse rotation output, fan

alarm∗3, heatsink overheat pre-alarm, deceleration at an instantaneous power failure, PID control activated, PID

output interruption, during retry, life alarm, current average value monitor, remote output, alarm output, fault

output, fault output 3, and maintenance timer alarm

For meter

Output points

Analog output

0 to 10VDC: one point

For meter

You can select from among output frequency, output current (steady), output voltage, frequency setting, converter

output voltage, regenerative brake duty, electronic thermal relay function load factor, output current peak value,

converter output voltage peak value, reference voltage output, motor load factor, PID set point, PID measured

value, output power, PID deviation, motor thermal load factor, inverter thermal load factor

0 to 10VDC

Indication

Operation panel

Parameter unit

(FR-PU07)

Operating status

You can select from among output frequency, output current (steady), output voltage, frequency setting,

cumulative energization time, actual operation time, converter output voltage, regenerative brake duty, electronic

thermal relay function load factor, output current peak value, converter output voltage peak value, motor load

factor, PID set point, PID measured value, PID deviation, inverter I/O terminal monitor, output power, cumulative

power, motor thermal load factor, inverter thermal load factor, PTC thermistor resistance.

Fault definition

Fault definition is displayed when the fault occurs and the past 8 fault definitions (output voltage/current/

frequency/cumulative energization time right before the fault occurs) are stored

Additional display

by the parameter

unit (FR-PU04/FR-

PU07) only

Operating status

Not used

Fault definition

Output voltage/current/frequency/cumulative energization time immediately before the fault occurs

Interactive

guidance

Function (help) for operation guide

Protective/warning

function

Protective

functions

Overcurrent during acceleration, overcurrent during constant speed, overcurrent during deceleration, overvoltage

during acceleration, overvoltage during constant speed, overvoltage during deceleration, inverter protection

thermal operation, motor protection thermal operation, heatsink overheat, input phase loss∗5 ∗6, output side earth

(ground) fault overcurrent at start∗5, output phase loss, external thermal relay operation ∗5, PTC thermistor

operation∗5, parameter error, PU disconnection, retry count excess ∗5, CPU fault, brake transistor alarm, inrush

resistance overheat, analog input error, stall prevention operation, output current detection value exceeded ∗5,

safety circuit fault

Warning

functions

Fan alarm∗3, overcurrent stall prevention, overvoltage stall prevention, PU stop, parameter write error,

regenerative brake prealarm ∗5, electronic thermal relay function prealarm, maintenance output ∗5, undervoltage,

operation panel lock, password locked, inverter reset, safety stop

Environment

Surrounding air temperature

-10°C to +50°C (14°F to 122°F) (non-freezing) ∗4

Ambient humidity

90%RH maximum (non-condensing)

Storage temperature∗2

-20°C to +65°C (-4°F to 149°F)

Atmosphere

Indoors (without corrosive gas, flammable gas, oil mist, dust and dirt etc.)

Altitude/vibration

Maximum 1000m (3280.80 feet) above sea level, 5.9m/s

2

or less

∗1 The braking torque indicated is a short-duration average torque (which varies with motor loss) when the motor alone is decelerated from 60Hz in the

shortest time and is not a continuous regenerative torque. When the motor is decelerated from the frequency higher than the base frequency, the average

deceleration torque will reduce. Since the inverter does not contain a brake resistor, use the optional brake resistor when regenerative energy is large. A

brake unit (FR-BU2) may also be used.

∗2 Temperatures applicable for a short time, e.g. in transit.

∗3 As the FR-D720-042 or less, FR-D740-022 or less, FR-D720S-042 or less is not provided with the cooling fan, this alarm does not function.

∗4 When using the inverters at the surrounding air temperature of 40°C (104°F) or less, the inverters can be installed closely attached (0cm clearance).

∗5 This protective function does not function in the initial status.

∗6 This protective function is available with the three-phase power input specification model only.