8

Installation of the inverter and enclosure design

1.4 Installation of the inverter and enclosure design

When an inverter panel is to be designed and manufactured, heat generated by contained equipment, etc., the environment of

an operating place, and others must be fully considered to determine the panel structure, size and equipment layout. The

inverter unit uses many semiconductor devices. To ensure higher reliability and long period of operation, operate the inverter

in the ambient environment that completely satisfies the equipment specifications.

1.4.1 Inverter installation environment

As the inverter installation environment should satisfy the standard specifications indicated in the following table, operation in

any place that does not meet these conditions not only deteriorates the performance and life of the inverter, but also causes a

failure. Refer to the following points and take adequate measures.

(1) Temperature

The permissible surrounding air temperature of the inverter is between -10 and +50

°

C

(14

°

F to 122

°

F). Always operate the

inverter within this temperature range. Operation outside this range will considerably shorten the service lives of the

semiconductors, parts, capacitors and others. Take the following measures so that the surrounding air temperature of the

inverter falls within the specified range.

1) Measures against high temperature

Use a forced ventilation system or similar cooling system. (Refer to page 10)

Install the panel in an air-conditioned electrical chamber.

Block direct sunlight.

Provide a shield or similar plate to avoid direct exposure to the radiated heat and wind of a heat source.

Ventilate the area around the panel well.

2) Measures against low temperature

Provide a space heater in the enclosure.

Do not power off the inverter. (Keep the start signal of the inverter off.)

3) Sudden temperature changes

Select an installation place where temperature does not change suddenly.

Avoid installing the inverter near the air outlet of an air conditioner.

If temperature changes are caused by opening/closing of a door, install the inverter away from the door.

(2) Humidity

Normally operate the inverter within the 45 to 90% range of the ambient humidity. Too high humidity will pose problems of

reduced insulation and metal corrosion. On the other hand, too low humidity may produce a spatial electrical breakdown. The

insulation distance specified in JEM1103 "Control Equipment Insulator" is defined as humidity 45 to 85%.

1) Measures against high humidity

Make the panel enclosed, and provide it with a hygroscopic agent.

Take dry air into the enclosure from outside.

Provide a space heater in the enclosure.

2) Measures against low humidity

What is important in fitting or inspection of the unit in this status is to discharge your body (static electricity)

beforehand and keep your body from contact with the parts and patterns, besides blowing air of proper humidity into

the enclosure from outside.

3) Measures against condensation

Condensation may occur if frequent operation stops change the in-enclosure temperature suddenly or if the outside-

air temperature changes suddenly.

Condensation causes such faults as reduced insulation and corrosion.

Take the measures against high humidity in 1).

Do not power off the inverter. (Keep the start signal of the inverter off.)

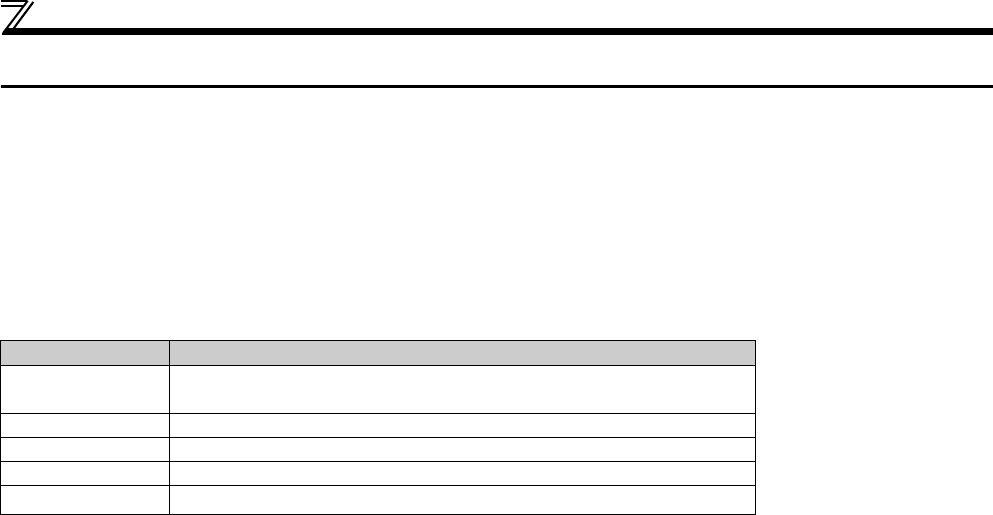

Environmental standard specifications of inverter

Item Description

Surrounding air

temperature

-10 to +50

°

C

(14

°

F to 122

°

F)(non-freezing)

Ambient humidity 90%RH maximum (non-condensing)

Atmosphere Free from corrosive and explosive gases, free from dust and dirt

Maximum altitude 1,000m (3280.80 feet) or less

Vibration

5.9m/s

2

or less