75

Adjust the output torque (current) of the motor

PARAMETERS

4

4.3.2 Large starting torque and low speed torque are necessary (General-purpose

magnetic flux vector control (Pr. 71, Pr. 80))

(1) Control mode

V/F control (initial setting) and General-purpose magnetic flux vector control are available with this inverter.

V/F control is for controlling frequency and voltage so that the ratio of frequency (F) to voltage (V) is constant when

changing frequency.

General-purpose magnetic flux vector control divides the inverter output current into an excitation current and a torque

current by vector calculation, and makes voltage compensation to flow a motor current which meets the load torque.

(General-purpose magnetic flux vector control is the same function as the FR-E500 series.)

General-purpose magnetic flux vector control is available.

Large starting torque and low speed torque are available with General-purpose magnetic flux vector control.

What is General-purpose magnetic flux vector control ?

The low speed torque can be improved by providing voltage compensation to flow a motor current which meets the

load torque. With setting slip compensation (Pr. 245 to Pr. 247), output frequency compensation (slip compensation) is

made so that the actual motor speed goes closer to a speed command value. Effective when load fluctuates

drastically, etc.

General-purpose magnetic flux vector control is the same function as the FR-E500 series.

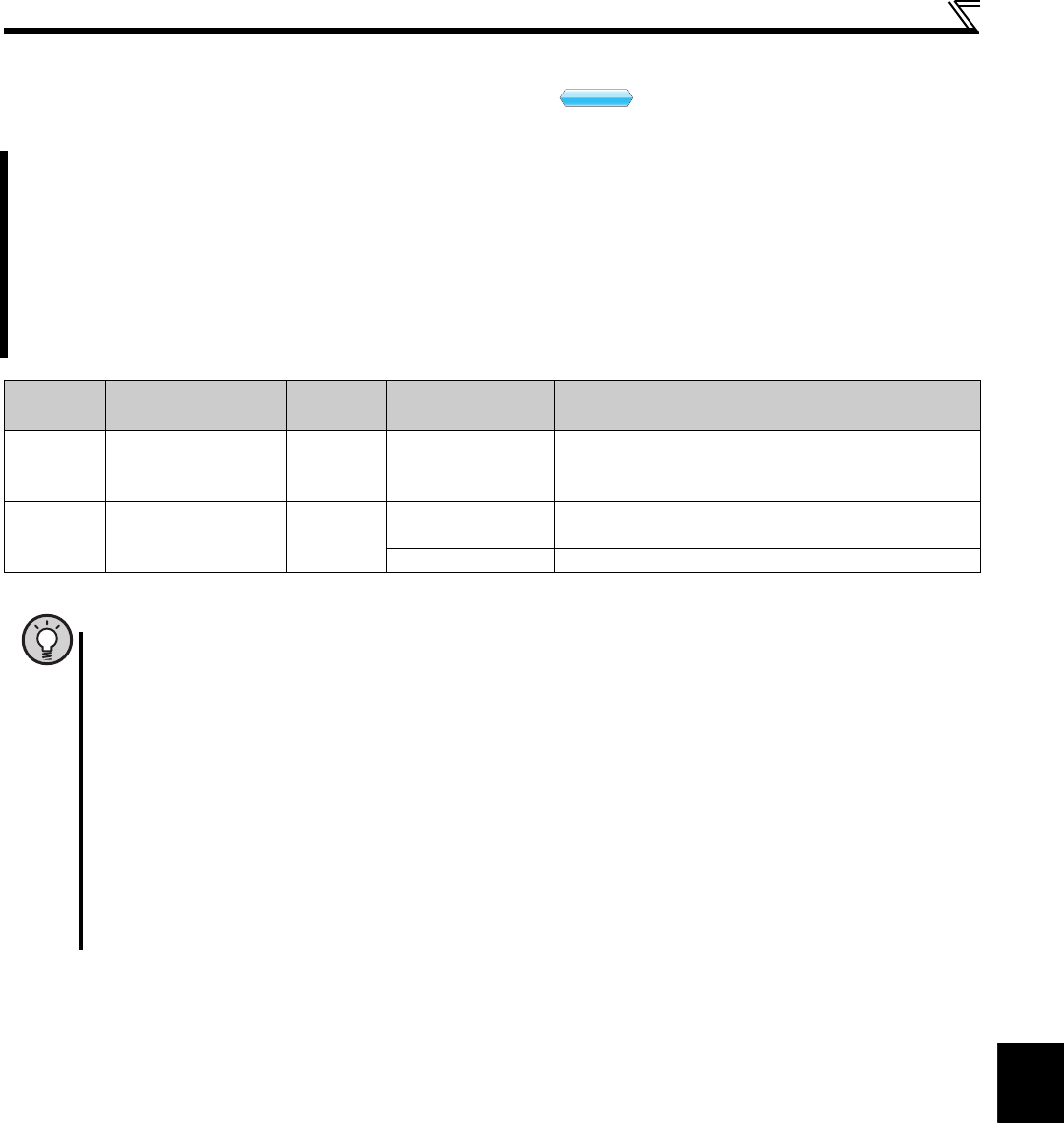

Parameter

Number

Name

Initial

Value

Setting Range Description

71 Applied motor

0

0,1, 3,

13, 23, 40, 43

50, 53

By selecting a standard motor or constant torque motor,

thermal characteristic and motor constants of each motor

are set.

80 Motor capacity

9999

0.1 to 7.5kW

Applied motor capacity. (General-purpose magnetic flux

vector control)

9999 V/F control

The above parameters can be set when Pr. 160 Extended function display selection = "0". (Refer to page 162)

POINT

If the following conditions are not satisfied, select V/F control since malfunction such as insufficient torque and

uneven rotation may occur.

The motor capacity should be equal to or one rank lower than the inverter capacity. (note that the capacity

should be 0.1kW or more)

Motor to be used is any of Mitsubishi standard motor, high efficiency motor (SF-JR, SF-HR 0.2kW or more) or

Mitsubishi constant torque motor (SF-JRCA four-pole, SF-HRCA 0.4kW to 7.5kW). When using a motor other

than the above (other manufacturer's motor), perform offline auto tuning without fail.

Single-motor operation (one motor run by one inverter) should be performed.

The wiring length from inverter to motor should be within 30m (98.42feet). (Perform offline auto tuning in the

state where wiring work is performed when the wiring length exceeds 30m (98.42feet).)

Permissible wiring length between inverter and motor differs according to the inverter capacity and setting value

of Pr. 72 PWM frequency selection (carrier frequency). Refer to page 19 for the permissible wiring length.

GP

MFVC

GP

MFVC

GP

MFVC