216

Special operation and frequency control

(4) I/O signals and parameter setting

Set "20, 21" in Pr. 128 to perform PID operation.

Set "14" in any of Pr. 178 to Pr. 182 (input terminal function selection) to assign PID control selection signal (X14) to turn the

X14 signal on.

When the X14 signal is not assigned, only the Pr. 128 setting makes PID control valid.

Enter the set point using the inverter terminal 2 or Pr. 133 and enter the measured value to terminal 4.

REMARKS

When Pr. 128 = "0" or X14 signal is off, normal inverter operation is performed without PID action.

Turning ON/OFF of bit of the terminal, to which X14 signal is assigned through network as RS-485 communication, enables

PID control.

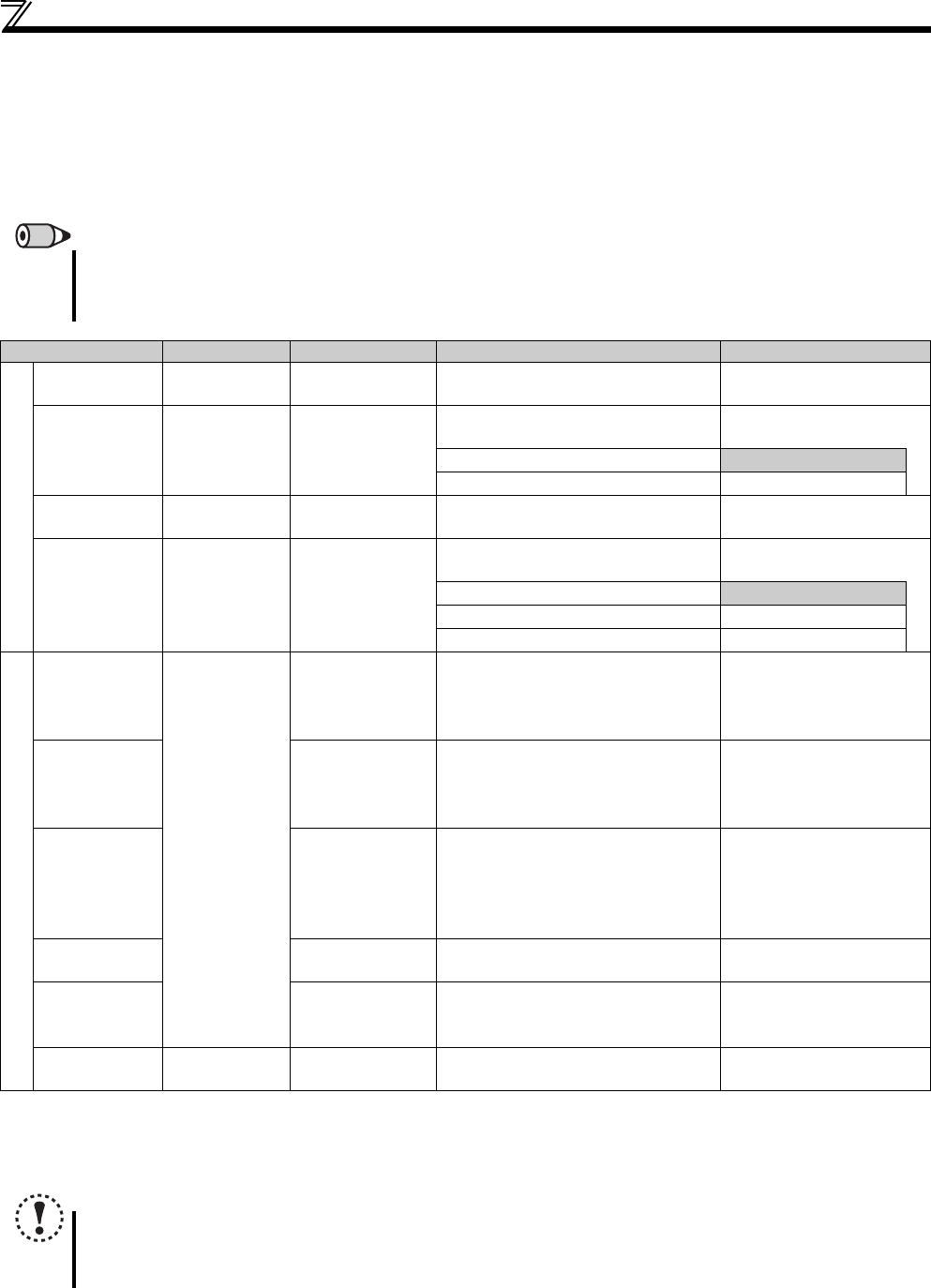

Signal Terminal Used Function Description Parameter Setting

Input

X14

Depending on

Pr. 178 to Pr. 182

PID control

selection

Turn on X14 signal to perform PID

control. ∗1

Set 14 in any of Pr. 178 to Pr.

182.

2 2 Set point input

You can input the set point for PID

control.∗4

Pr. 128 = 20, 21,

Pr. 133 = 9999

0 to 5V..............0 to 100%

Pr. 73 = 1 ∗2, 11

0 to 10V............0 to 100%

Pr. 73 = 0, 10

PU — Set point input

Set the set point (Pr. 133) from the

operation panel.

Pr. 128 = 20, 21

Pr. 133 = 0 to 100%

44

Measured value

input

Input the signal from the detector

(measured value signal).

Pr. 128 = 20, 21

4 to 20mA.........0 to 100%

Pr. 267 = 0 ∗2

0 to 5V..............0 to 100%

Pr. 267 = 1

0 to 10V............0 to 100%

Pr. 267 = 2

Output

FUP

Depending on

Pr. 190, Pr. 192

Upper limit output

Output to indicate that the process value

signal exceeded the maximum value (Pr.

131).

Pr. 128 = 20, 21

Pr. 131 ≠ 9999

Set 15 or 115 in Pr. 190

or Pr. 192 ∗3

FDN Lower limit output

Output when the process value signal

falls below the minimum value (Pr. 132).

Pr. 128 = 20, 21

Pr. 132 ≠ 9999

Set 14 or 114 in Pr. 190

or Pr. 192. ∗3

RL

Forward (reverse)

rotation direction

output

"Hi" is output to indicate that the output

indication of the parameter unit is

forward rotation (FWD) or "Low" to

indicate that it is reverse rotation (REV)

or stop (STOP).

Set 16 or 116 in Pr. 190

or Pr. 192. ∗3

PID

During PID control

activated

Turns ON during PID control.

Set 47 or 147 in Pr. 190

or Pr. 192. ∗3

SLEEP

PID output

interruption

Turns ON when the PID output

interruption function is performed.

Pr. 575 ≠9999

Set 70 or 170 in Pr. 190 or

Pr.192. ∗3

SE SE

Output terminal

common

Common terminal for open collector

output terminal.

∗1 When the X14 signal is not assigned, only the Pr. 128 setting makes PID control valid.

∗2 The shaded area indicates the parameter initial value.

∗3

When 100 or larger value is set in any of

Pr.190, Pr.192 (output terminal function selection)

, the terminal output has negative logic.

(Refer to page 119 for details)

∗4

When

Pr. 561 PTC thermistor protection level

≠

"9999", terminal 2 is not available for set point input.

Use

Pr. 133

for set point input.

NOTE

Changing the terminal function using any of Pr. 178 to Pr. 182 and Pr. 190, Pr. 192 may affect the other functions. Make

setting after confirming the function of each terminal.

When the Pr. 267 setting was changed, check the voltage/current input switch setting. Different setting may cause a

fault, failure or malfunction. (Refer to page 150 for setting)