222

Special operation and frequency control

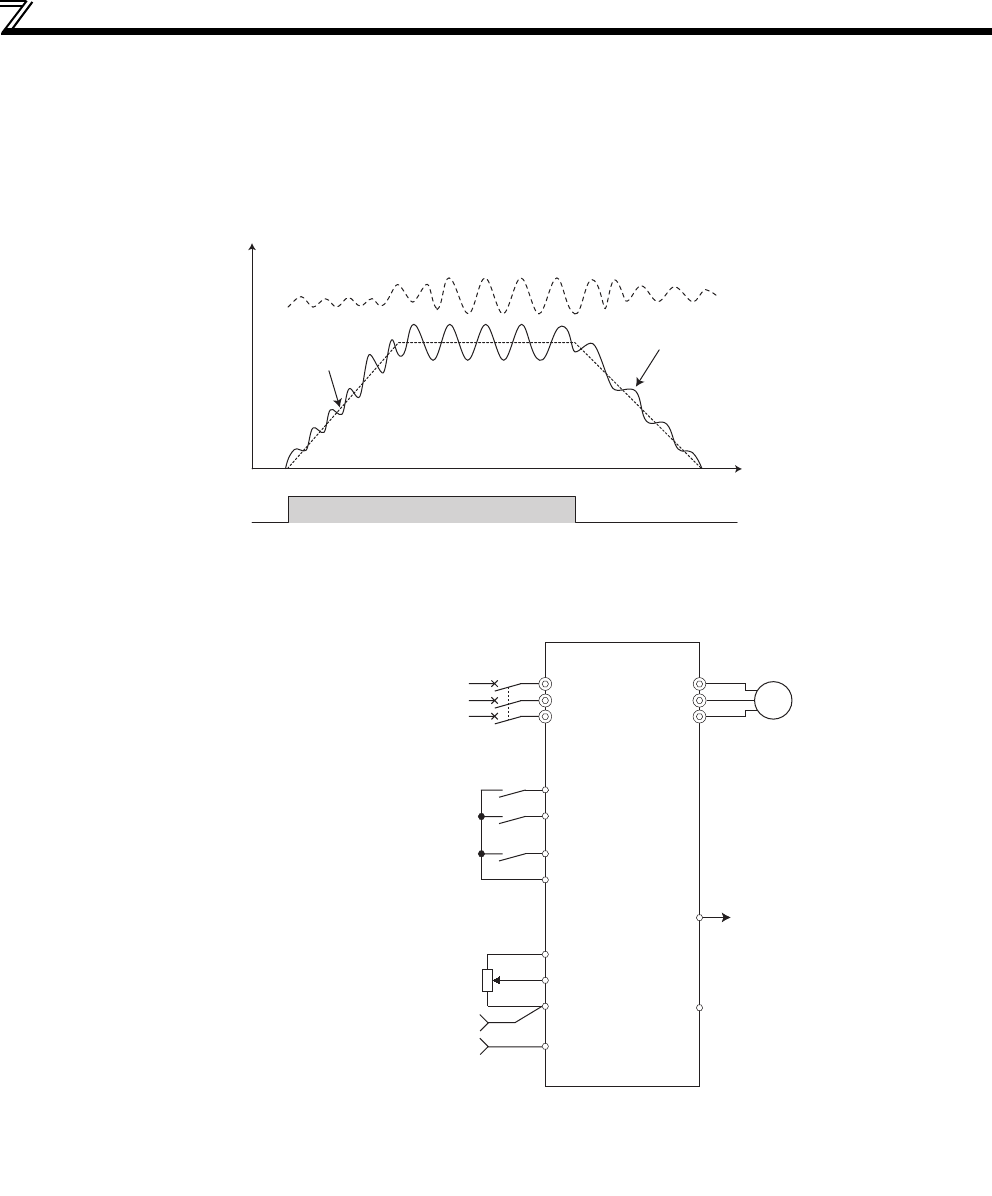

(2) Dancer control overview

Performs dancer control by setting 40 to 43 in Pr. 128 PID action selection.The main speed command is the speed command of

each operation mode (external, PU, communication). Performs PID control by the position detection signal of the dancer

roller, then the result is added to the main speed command. For acceleration/deceleration of the main speed, set the

acceleration time in Pr. 44 Second acceleration/deceleration time/Pr. 45 Second deceleration time.

* Set 0s normally to Pr. 7 Acceleration time and Pr.8 Deceleration time. When the Pr. 7 and Pr. 8 setting is large, response of dancer control during acceleration/

deceleration is slow.

(3) Connection diagram

Sink logic

Pr. 128 = 41

Pr. 182 = 14

Pr. 190 = 15

Pr. 192 = 16

∗1 The main speed command differs according to each operation mode (external, PU, communication)

∗2 The used output signal terminal changes depending on the Pr. 190, Pr. 192 (output terminal selection) setting.

∗3 The used input signal terminal changes depending on the Pr. 178 to Pr. 182(input terminal selection) setting.

∗4 The AU signal need not be input.

STF

PID adding value

Main speed

ON

Output frequency

Time

Output frequency

Power supply

MCCB

Inverter

Forward rotation

Reverse rotation

PID control selection

Main speed commnad

setting potentiometer

*1

R/L1

S/L2

T/L3

STF

STR

RH(X14)

*3

SD

10

2

5

4

*4

U

V

W

*2 (FUP)RUN

SE

Motor

IM

Upper limit

Output signal common

Feedback value of

dancer roll position