- 17 -

1.3.3 Wiring of the main circuit

• The high power factor converter (FR-HC) is a high-power factor, low-noise inverter option unit designed for

use with the transistorized inverters (FR-HC compatible models) in accordance with the harmonic

suppression guidelines published by Ministry of Economy Trade and Industry (formerly Ministry of

International, Trade and Industry). This high power factor converter is used for the suppression of

harmonics to an input power supply.

• To comply with the harmonic suppression guidelines published by the MITI, the system needs to be

configured as indicated and make sure that terminals P and N are sacurely connected to terminals P and N

of the inverter. An incorrect connection will cause the high power factor converter to display an alarm or to

be faulty or damaged.

• Refer to the inverter instruction manual on how to wire the system to suppress harmonics to the input

power supply. Especially note the wiring distance and cable size.

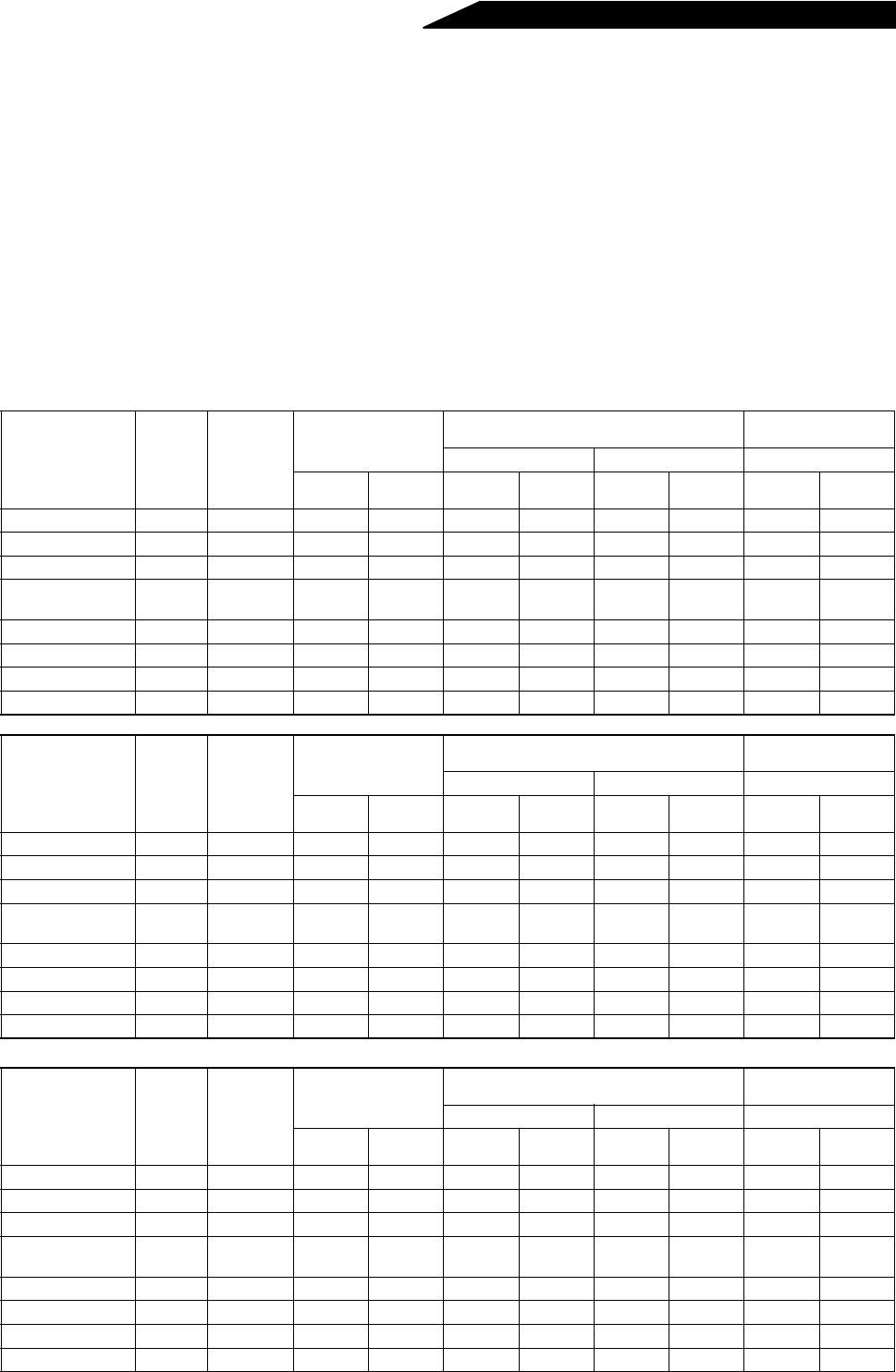

(1) Cable, Crimping terminals etc.

The following table lists the cables and crimping terminals used for each of the devices of the High

power factor converter system and the torques for tightening the screws:

Type

Terminal

screw

size

Tightening

torque

N

·

m *3

Crimping

terminal *2

Cables

PVC insulated

Cables

mm

2

AWG

*

1mm

2 *

4

R4, S4,

T4

P, N

R4, S4,

T4

P, N

R4, S4,

T4

P, N

R4, S4,

T4

P, N

FR-HC-7.5K M4 1 8-4 8-4 8 8 8 8 6 6

FR-HC-15K M6 4 22-6 22-6 22 22 4 4 16 16

FR-HC-30K M8 7 60-8 60-8 60 60 1/0 1/0 50 50

FR-HC-55K M12 24 150-12 150-12 150 150

MCM

300

MCM

300

––

FR-HC-H7.5K M4 1 3.5-4 3.5-4 3.5 3.5 12 12 4 4

FR-HC-H15K M6 4 8-6 8-6 8 8 8 8 10 10

FR-HC-H30K M6 4 22-6 22-6 22 22 4 4 25 25

FR-HC-H55K M8 7 60-8 60-8 60 60 1/0 1/0 50 50

Type

Terminal

screw

size

Tightening

torque

N

·

m *3

Crimping

terminal *2

Cables

PVC insulated

Cables

mm

2

AWG

*

1mm

2 *

4

R2, S2,

T2

R3, S3,

T3

R2, S2,

T2

R3, S3,

T3

R2, S2,

T2

R3, S3,

T3

R2, S2,

T2

R3, S3,

T3

FR-HCB-7.5K M5 2 8-5 8-5 8 8 8 8 6 6

FR-HCB-15K M5 2 22-5 22-5 22 22 4 4 16 16

FR-HCB-30K M6 4 60-6 60-6 60 60 1/0 1/0 50 50

FR-HCB-55K M8 7 150-8 150-8 150 150

MCM

300

MCM

300

––

FR-HCB-H7.5K M5 2 3.5-5 3.5-5 3.5 3.5 12 12 4 4

FR-HCB-H15K M5 2 8-5 8-5 8 8 8 8 10 10

FR-HCB-H30K M5 2 22-5 22-5 22 22 4 4 25 25

FR-HCB-H55K M8 7 60-8 60-8 60 60 1/0 1/0 50 50

Type

Terminal

screw

size

Tightening

torque

N

·

m *3

Crimping

terminal *2

Cables

PVC insulated

Cables

mm

2

AWG

*

1mm

2 *

4

R, S, T

R2, S2,

T2

R, S, T

R2, S2,

T2

R, S, T

R2, S2,

T2

R, S, T

R2, S2,

T2

FR-HCL01-7.5K M5 2 8-5 8-5 8 8 8 8 6 6

FR-HCL01-15K M6 4 22-6 22-6 22 22 4 4 16 16

FR-HCL01-30K M8 7 60-8 60-8 60 60 1/0 1/0 50 50

FR-HCL01-55K M12 24 150-12 150-12 150 150

MCM

300

MCM

300

––

FR-HCL01-H7.5K M4 1 3.5-4 3.5-4 3.5 3.5 12 12 4 4

FR-HCL01-H15K M5 2 8-5 8-5 8 8 8 8 10 10

FR-HCL01-H30K M6 4 22-6 22-6 22 22 4 4 25 25

FR-HCL01-H55K M8 7 60-8 60-8 60 60 1/0 1/0 50 50