Airport Systems

SG-60 High Intensity Strobe System 2-15 Manual EPM-00000019 Rev A

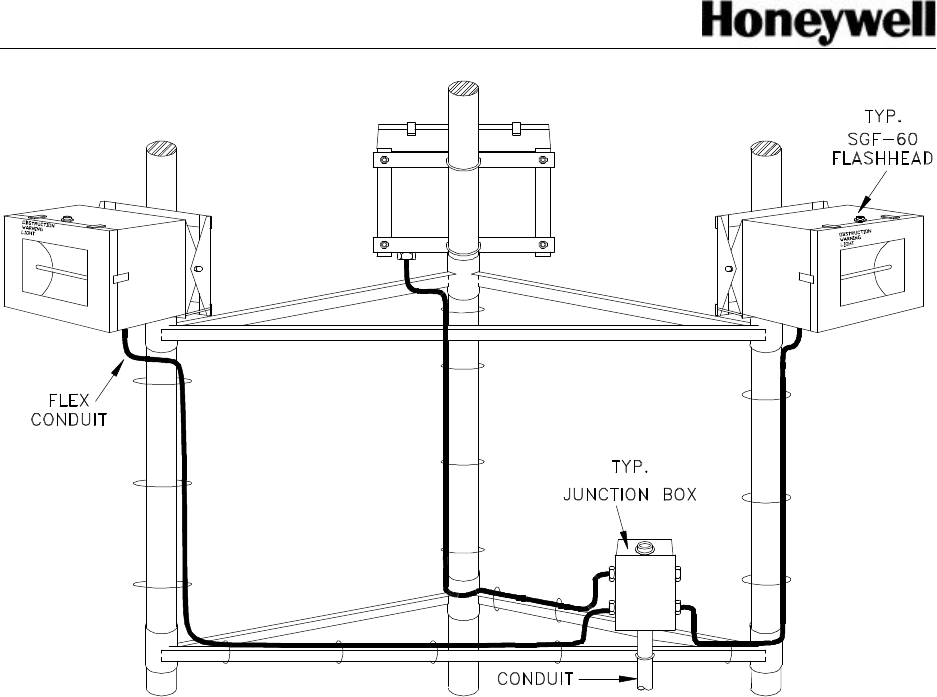

Figure 2-5: Flex Conduit Typical Installation Layout

2.4.6.1 Procedures for installation of conduit and tower wiring

1. All conduit, junction boxes, mounting hardware, fixtures, etc. provided for

installation of the electrical system (i.e. lighting or equipment power distribution)

should be inventoried and checked against the appropriate bills of materials.

(a) Conduit and junction box components provided for electrical

systems should be checked against appropriate bills of materials to

ensure all are present and of proper size.

(b) Numbers of wires to be carried by each conduit run should be

checked against National Electrical Code. Honeywell sizes the

conduit run for a 40% fill of the conduit by the NEC.

2. Use pipe compound or equivalent for all threaded connections in the conduit

run. This will prevent water from entering the conduit system and make an

electrical connection between the conduit and ground.

3. All custom cut pieces of conduit must be de-burred after they are threaded to

remove sharp edges that may cut wiring insulation. Honeywell supplies conduit

in 10-foot lengths, therefore cutting and threading of the conduit may be

necessary.

4. Insure that “chase nipples” or bushings are properly installed in all junction box

ports to protect the wiring insulation from pipe threads and other sharp edges in