38

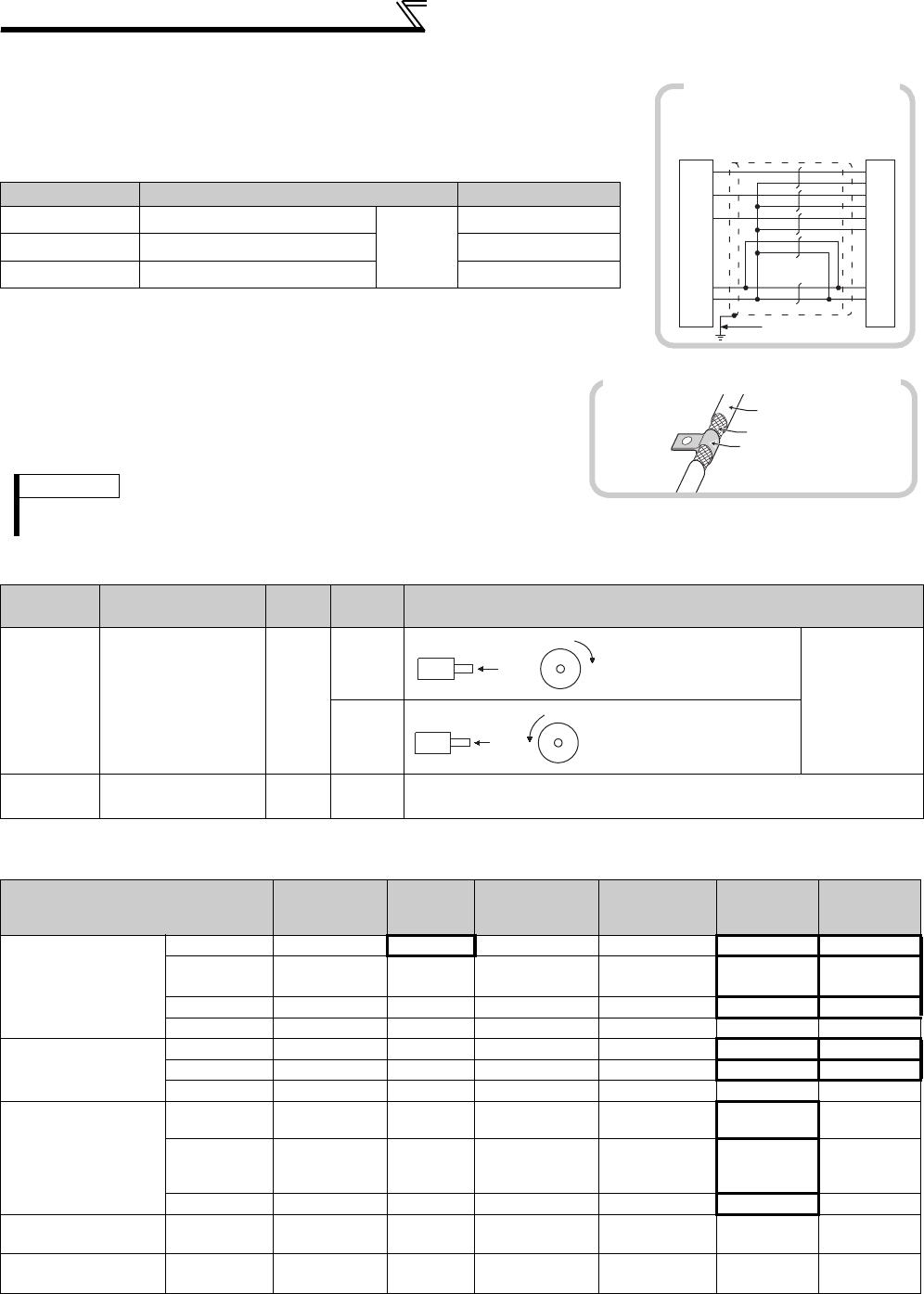

Connection of motor with encoder (vector control)

(6) Instructions for encoder cable wiring

• Use shielded twisted pair cables (0.2mm

2

or larger) to connect the FR-A7AP

and position detector. Cables to terminals PG and SD should be connected in

parallel or be larger in size according to the cable length.

To protect the cables from noise, run them away from any source of noise (e.g.

the main circuit and power supply voltage).

* When differential line driver is set and a wiring length is 30m or more

The wiring length can be extended to 100m by slightly increasing the power by 5V (approx. 5.5V)

using six or more cables with gauge size of 0.2mm

2

in parallel or a cable with gauge size of 1.25mm

2

or more. Note that the voltage applied should be within power supply specifications of encoder.

• To reduce noise of the encoder cable, earth (ground) the encoder

shielded cable to the enclosure (as close as possible to the inverter)

with a P-clip or U-clip made of metal.

(7) Parameter for encoder (Pr. 359, Pr. 369)

(8) Motor for vector control and parameter setting

Wiring Length Parallel Connection Larger-Size Cable

Within 10m At least two cables in parallel

Cable

gauge

0.2mm

2

0.4mm

2

or larger

Within 20m At least four cables in parallel

0.75mm

2

or larger

Within 100m * At least six cables in parallel

1.25mm

2

or larger

REMARKS

· For details of the optional encoder dedicated cable (FR-JCBL/FR-V7CBL), refer to page 35.

· The FR-V7CBL is provided with a P clip for earthing (grounding) shielded cable.

Parameter

Number

Name

Initial

Value

Setting

Range

Description

359

Encoder rotation

direction

1

0 Set the rotation

direction

according to

the motor

specification.

1

369

Number of

encoder pulses

1024

0 to

4096

Set the number of encoder pulses output.

Set the number of pulses before it is multiplied by 4.

The above parameters can be set when the FR-A7AP/FR-A7AL (option) is mounted.

Motor Name

Pr. 9

Electronic thermal

O/L relay

Pr. 71

Applied motor

Pr. 80

Motor capacity

Pr. 81

Number of motor

poles

Pr. 359

Encoder rotation

direction

Pr. 369

Number of

encoder pulses

Mitsubishi standard

motor

SF-JR

Motor rated current

0 Motor capacity

Number of motor poles

1 1024

SF-JR 4P 1.5kW

or lower

Motor rated current

20 Motor capacity 4 1 1024

SF-HR

Motor rated current

40 Motor capacity

Number of motor poles

1 1024

Others

Motor rated current

3 *1 Motor capacity

Number of motor poles

*2 *2

Mitsubishi constant-

torque motor

SF-JRCA 4P

Motor rated current

1 Motor capacity 4 1 1024

SF-HRCA

Motor rated current

50 Motor capacity

Number of motor poles

1 1024

Others

Motor rated current

13 *1 Motor capacity

Number of motor poles

*2 *2

Mitsubishi vector

control dedicated

motor

SF-V5RU

(1500r/min series)

0 *3 30 Motor capacity 4 1 2048

SF-V5RU

(except for 1500r/

min series)

0 *3 13 *1 Motor capacity 4 1 2048

SF-THY 0

*3 33 *1 Motor capacity 4 1 2048

Other manufacturer's

standard motor

—

Motor rated current

3 *1 Motor capacity

Number of motor poles

*2 *2

Other manufacturer's

constant-torque motor

—

Motor rated current

13 *1 Motor capacity

Number of motor poles

*2 *2

Values in the bolded frame are initial values.

*1 Offline auto tuning is necessary. (Refer to page 189)

*2 Set this parameter according to the motor (encoder) used.

*3 Use thermal protector input provided with the motor.

PZ2

PZ1

PA1

PA2

FB1

FB2

SD

PG

G

F

D

C

B

A

R

S

PLG

2mm

2

FR-A700

(FR-A7AP)

Example of parallel connection

with two cables

(with complementary encoder output)

Encoder cable

Shield

P-clip

Earthing (grounding) example using a P-clip

Forward rotation is clockwise

rotation when viewed from A.

A

Encoder

CW

A

Encoder

CCW

Forward rotation is counterclockwis

e

rotation when viewed from A.