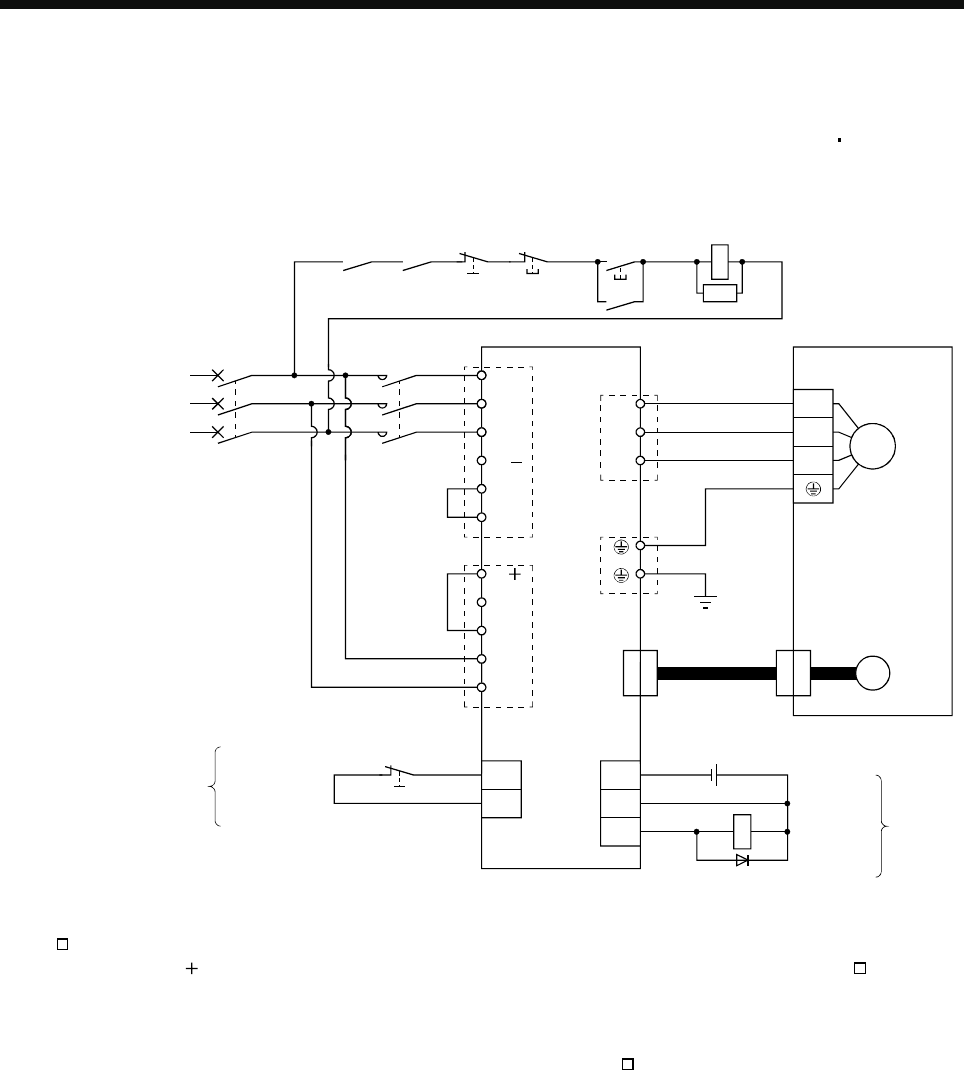

3. SIGNALS AND WIRING

3 - 4

3.2.2 Connection example

(1) For 3-phase 200 to 230VAC power supply to MR-J3-20B-RJ080W to MR-J3-100B-RJ080W

MR-J3-350B-RJ080W

(Note 4)

EM1

ALM

DICOM

DOCOM

24VDC

Malfunction

(Note 3)

DOCOM

Forced stop

(Note 6)

CN3CN3

(Note 4)

MC (Note 8)

MCCB

L

1

L

2

L3

3-phase

200 to

230VAC

Servo amplifier

P

1

P

2

P( )

L

11

L21

N( )

D

C

U

V

W

(Note 1)

(Note 2)

CNP1

CNP3

PE

CNP2

Direct drive motor

U

V

W

M

Motor

Encoder

CN2

Encoder cable

(Note 5)

(Note 3)

Malfunct

ion

RA1

Controller

forced stop

RA1

(Note 7)

OFF

MC

ON

MC

SK

(Note 6)

Forced stop

RA2

Note 1. Always connect P1 and P2. (Factory-wired.) When using the power factor improving DC reactor, refer to chapter 11 of the MR-J3-

B Servo Amplifier Instruction Manual. Use either the power factor improving DC reactor or the power factor improving AC reactor.

2. Always connect P(

) and D. (Factory-wired.) When using the regenerative option, refer to chapter 11 of the MR-J3- B Servo

Amplifier Instruction Manual.

3. If deactivating output of malfunction (ALM) with parameter change, configure up the power supply circuit which switches off the

magnetic contactor after detection of alarm occurrence on the controller side.

4. For sink I/O interface. For source I/O interface, refer to section 3.7.3 of the MR-J3-

B Servo Amplifier Instruction Manual.

5. For details of connection of the servo amplifier and direct drive motor, refer to section 2.5.5.

6. Configure the circuit to shut down the main circuit power supply simultaneously with the turn off of forced stop (EM1) using the

external sequence.

7. This connector detects speed, position and temperature of the direct drive motor. (Refer to chapter 9.)

8. Be sure to use a magnetic contactor with an operation delay time of 80ms or less. The operation delay time is the time interval

between current being applied to the magnetic coil until closure of contacts.