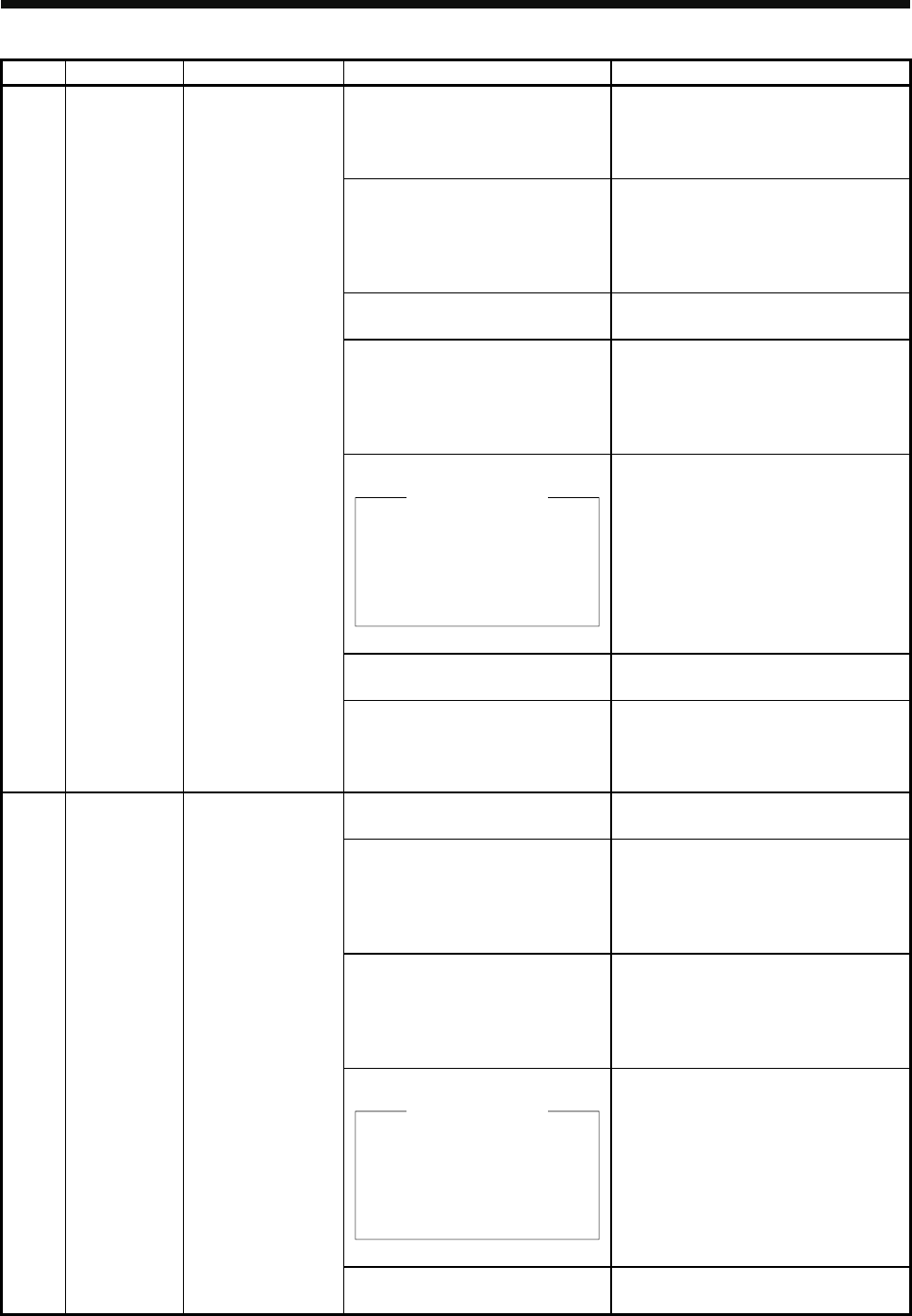

6. TROUBLESHOOTING

6 - 5

Display Name Definition Cause Action

50 Overload1 1. Servo amplifier is used in excess of

its continuous output current.

1. Reduce load.

2. Check operation pattern.

3. Replace direct drive motor that provides

larger output.

Load exceeded

overload protection

characteristic of servo

amplifier.

2. Servo system is instable and

hunting.

1. Repeat acceleration/

deceleration to execute auto tuning.

2. Change auto tuning response setting.

3. Set auto tuning to off and make gain

adjustment manually.

3. Machine struck something. 1. Check operation pattern.

2. Install limit switches.

4. Wrong connection of direct drive

motor. Servo amplifier's power

supply output (U, V, and W) do not

match direct drive motor's power

supply input (U, V, and W).

Connect correctly.

5. Encoder faulty.

Checking method

When the direct drive motor rotor

is rotated with the servo-off, the

cumulative feedback pulses do

not vary in proportional to the

turning angle in the rotor, and the

indication skips or returns

midway.

Replace the direct drive motor.

6. Initial magnetic pole detection has

not been performed.

Perform initial magnetic pole detection.

7. After Overload 2 (51) occurred, turn

off/on the power supply to clear the

alarm. Then the overload operation

is repeated.

1. Reduce load.

2. Check operation pattern.

3. Replace direct drive motor that provides

larger output.

51 Overload2 1. Machine struck something. 1. Check operation pattern.

2. Install limit switches.

2. Wrong connection of direct drive

motor. Servo amplifier's power

supply output (U, V, and W) do not

match direct drive motor's power

supply input (U, V, and W).

Connect correctly.

Machine collision or

the like caused max.

output current to flow

successively for

several seconds.

For the time of the

alarm occurrence,

refer to the section

8.1.

3. Servo system is instable and

hunting.

1. Repeat acceleration/deceleration to

execute auto tuning.

2. Change auto tuning response setting.

3. Set auto tuning to off and make gain

adjustment manually.

4. Encoder faulty.

Checking method

When the direct drive motor rotor

is rotated with the servo-off, the

cumulative feedback pulses do

not vary in proportional to the

turning angle in the rotor, and the

indication skips or returns

midway.

Replace the direct drive motor.

5. Initial magnetic pole detection has

not been performed.

Perform initial magnetic pole detection.