Features

Standard

Specifications

Outline

Dimension

Drawings

Operation

Panel

Protective

Functions

OptionsInstructionsMotorCompatibilityWarrantyInquiry

Peripheral Devices

Why energy

savings?

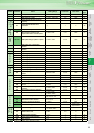

Terminal Connection

Diagram

Terminal Specification

Explanation

Parameter

List

Explanations

of

Parameters

16

CAUTION

⋅

To prevent a malfunction due to noise, keep the signal cables more than 10cm away from the power cables.

⋅ Be sure to use the inverter and motor after grounding (earthing) them.

⋅ This connection diagram assumes that the control circuit is sink logic (initial setting). Refer to the instruction manual for the

connection in the case of source logic.

Three-phase AC

power supply

MCCB

Jumper

R/L1

S/L2

T/L3

R1/L11

S1/L21

PC

10E(+10V)

10(+5V)

2

3

1

1

4

Control input signals (No voltage input allowed)

Jumper

Motor

Relay output 1

(Alarm output)

C1

B1

A1

U

V

W

AM

5

*1

Main circuit terminal

Control circuit terminal

MC

Main circuit

Control circuit

C2

B2

A2

Relay output 2

Relay output

IM

AU

PTC

TXD+

TXD-

RXD+

RXD-

SG

SINK

SOURCE

Terminal functions

vary with the output

terminal assignment

(Pr. 195, Pr. 196)

Terminal functions

vary with the output

terminal assignment

(Pr. 190 to Pr. 194)

Terminal functions

vary with the input

terminal assignment

(Pr. 178 to Pr. 189)

*3

STF

STR

STOP

RH

RM

RL

JOG

RT

MRS

RES

AU

CS

SD

RUN

SU

IPF

OL

FU

SE

Connector for

with/without

EMC filter

ON

OFF

VCC

Frequency setting signal (Analog)

Frequency setting

potentiometer

1/2W1k

Ω

Auxiliary input

(+)

(-)

2

(Analog common)

0 to 5VDC

0 to 10VDC

selected

4 to 20mADC

*

4

5

PU

connector

Terminal 4 input

(Current input)

Terminating

resistor

Connector

for plug-in option

connection

*

5. It is recommended to use

2W1kΩ when the

frequency setting signal is

changed frequently.

(+)

(-)

0 to 5VDC

0 to 10VDC

selected

*

4

GND

RS-485 terminals

Data transmission

Data reception

4 to 20mADC

*

4

selected

0 to ±5VDC

0 to

±

10VDC

(-)

(+)

(0 to 10VDC)

Analog signal output

Frequency detection

Open collector output common

Sink

/source common

Running

Up to frequency

Instantaneous

power failure

Overload

Open collector output

Terminal 4 input selection

(Current input selection)

Selection of automatic restart

after instantaneous

power failure

Output stop

Reset

*3. AU terminal

can be used

as PTC input

terminal.

Middle speed

High speed

Low speed

Jog mode

Second function selection

Multi-speed

selection

Forward

rotation

start

Reverse

rotation

start

Start self-holding selection

PR*7

PX*7

Jumper

*7.

*5

*

4. Terminal input

specifications can be

changed by analog input

specifications switchover

(Pr. 73, Pr. 267).

(Permissible load

current 100mA)

5V

*2. To supply power to the

control circuit separately,

remove the jumper across

R1/L11 and S1/L21.

*2

Do not use PR and PX terminals.

Please do not remove the jumper

connected to terminal PR and PX.

N/-

P/+

Option connector 1

P1

Resistor unit

(Option)

Brake unit

(Option)

CN8

*6

Sink logic

Earth

(Ground)

Earth

(ground)

cable

Earth

(ground)

+-

Indicator

(Frequency meter, etc.)

Moving-coil type

1mA full-scale

Calibration

resistor

*

9

SD

FM

24VDC power supply

(Common for external power supply transistor)

Contact input common

*1. DC reactor (FR-HEL)

Be sure to connect the DC reactor

supplied with the 75K or more.

When a DC reactor is connected

to the 55K or less, remove the

jumper across P1-P/+.

*6. A CN8 connector is

provided with the

75K or more.

*

9. It is not necessary

when calibrating the

indicator from the

operation panel.

*8.

The 200V class 0.75K and 1.5K

are not provided with the ON/OFF

connector of the EMC filter.

*8

Terminal Connection Diagram