43

Features

Standard

Specifications

Outline

Dimension

Drawings

Operation

Panel

Protective

Functions

OptionsInstructionsMotorCompatibilityWarrantyInquiry

Peripheral Devices

Why energy

savings?

Terminal Connection

Diagram

Terminal Specification

Explanation

Parameter

List

Explanations

of

Parameters

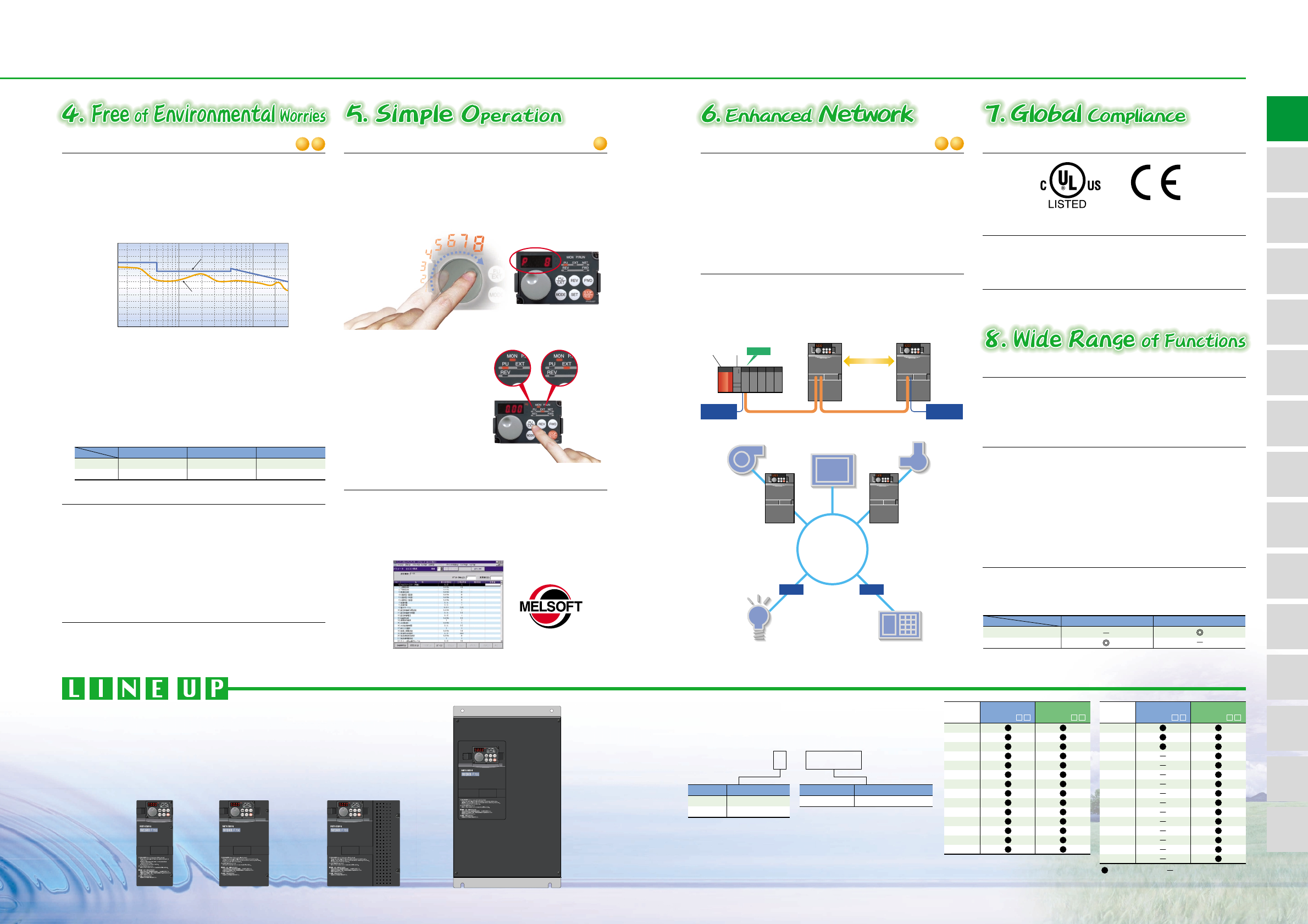

Full of attractive features!

•

I

nverter noises have been reduced with the adoption of new technologies.

¥

Because of the built-in capacitive filter and zero-phase reactor (55K or less),

connecting the optional DC reactor to the inverter will comply with the

electric installation work common specification and machine installation

work common specification (2001) written under the general editorship of

the Japanese Ministry of land, infrastructure and transportation.

¥Because of the built-in EMC filter, the inverter itself can

comply with the EMC Directive (2nd environment*

1

) by

setting the connector to "with filter"(*

2,

*

3

).

(1)

Reduction of electromagnetic noises

•

Because of the built-in inrush current limit circuit, the current

at power on is restricted.

(3)

Equipped with inrush current limit circuit

¥

AC reactor and DC reactor options for the control of

harmonics current output has been miniaturized.

(DC reactor is supplied with the 75K or more as standard.)

(2)

Countermeasures for harmonic current output

EF

•Newly developed noise filter (EMC filter)

(1)

Equipped with operation panel with the popular setting dial

•

From start up to maintenance of the inverter is simple.

•

Possible to save and print parameter setting file making

parameter management simple

(Possible to use communications connecting to any of PU connector and RS-485 terminals)

(2) FR Configurator (setup software)

AGH

•Operation is easy with the popular setting dial.

¥Frequency and parameters can be set without frustrations.

¥

Settings can be made quickly or slowly depending on fast

the dial is being turned.

¥

Settings are certain due to the "clicking" sensation and notch on dial.

•RS-485 terminals are available in addition to the PU.

connector. RS-485 communication can be performed using

the operation panel or parameter unit. Since terminals for

input and output are provided separately, multi-drop

connection is easily done.

•Modbus-RTU (Binary) protocol has been added for

communications in addition to computer link.

(1)

RS-485 terminal is standard equipped

(1)

Complies with UL, cUL, EN (LVD) standards

(1) Remote output function

(2)

Possible to switch sink/source with one-touch

•Possible to connect with LONWORKS, CC-Link Ver.1.1 and Ver.2.0,

DeviceNet

TM

and Profibus-DP when used with communication

options

•You can utilize the on/off of the inverter's output signals

instead of the remote output function of the programmable

logic controller.

•

Possible to switch the logic of I/O terminals. Possible to use in

all regions

(3) Wide voltage range

•

Accommodate both 240V power supply (55K or less) and

480V power supply as standard

(2) Enhanced I/O is standard

•12 contact inputs, 3 analog inputs, 5 open collector outputs, 2

relay outputs, analog output and pulse output are all standard.

•Possible to assign variety of functions to contact inputs, open

collector outputs and relay outputs

•

Possible to switch between voltage and current for the analog input.

•Possible to display the ON/OFF status of the I/O terminals on

the operation panel

(2)

Possible to correspond with major networks

•High torque in low speed region is possible with simple

magnetic flux vector control

(120% torque is possible at 3Hz with slip compensation)

(3)

Simple magnetic flux vector control is possible

For torque

For energy savings

V/F + Optimum Excitation

Simple Magnetic Flux Vector

Voltage

200V class

400V class

Symbol

2

4

0.75

1.5

2.2

3.7

5.5

7.5

11

15

18.5

22

30

37

45

55

Inverter Capacity

Indicate capacity (kW)

Symbol

0.75K to 560K

CC-Link

dedicated cable

CC-Link network

Inverter

Inverter

FR-A7NC FR-A7NC

Inverter

Master

CPU

Power

supply

unit

Terminating

resistor

Terminating

resistor

when connections

are inverter only

( )

Up to 42 units can

be connected

LONWORKS

Network

Free

Topology

Network management

computer

Pump

Air-conditioner

FR-A7NL

Inverter

FR-A7NL

Node Node

Security systemLighting

Example of parameter change

•Operation panel is detachable and can be installed on the

front cover. (Cable connector

option is required.)

•PU/EXT (operation mode)

switchover key is available.

•Dial/key operation lock

function is available.

PU/EXT

Example of

operation mode

•Small AC reactor (FR-HAL)/DC reactor (FR-HEL)

¥Connection is possible to high power-factor converter for effective

suppressions of power-supply harmonics (coefficient K5=0).

•

Connection with high power factor converter (FR-HC/MT-HC) is possible

75

90

110

132

160

185

220

250

280

315

355

400

450

500

560

Applied Motor

(kW)

Applied Motor

(kW)

130

120

110

100

90

80

70

60

50

40

30

20

10

0

.15 .2 .3 .5 .7 1 2 3 5 7 10 20 30

[dBuV]

Frequency [MHz]

[FR-F740-37K Conducted noise data]

EN61800-3

second Environment QP level

QP value

L

ON

W

ORKS

®

is a registered trademark of Echelon Corporation and DeviceNet is of ODVA.

:Available models :Not available

Three-phase 200V class

FR-F720-

Three-phase 400V class

FR-F740-

Three-phase 200V class

FR-F720-

Three-phase 400V class

FR-F740-

FR-F7 2 0- 0.75K

*1:

Refer to the EMC instruction manual for compliance conditions.

*2: Leakage current will increase when the EMC filter is selected.

*3: Since the leakage current when using the EMC filter for the 200V class 0.75K and

1.5K is small, the filter is always valid (a setting connector is not provided).

55K or less

75K or more

Capacitive filter

Standard (Built-in)

Standard (Built-in)

Zero-phase reactor

Standard (Built-in)

Option (Sell separately)

DC reactor

Option (Sell separately)

Standard (supplied)