3

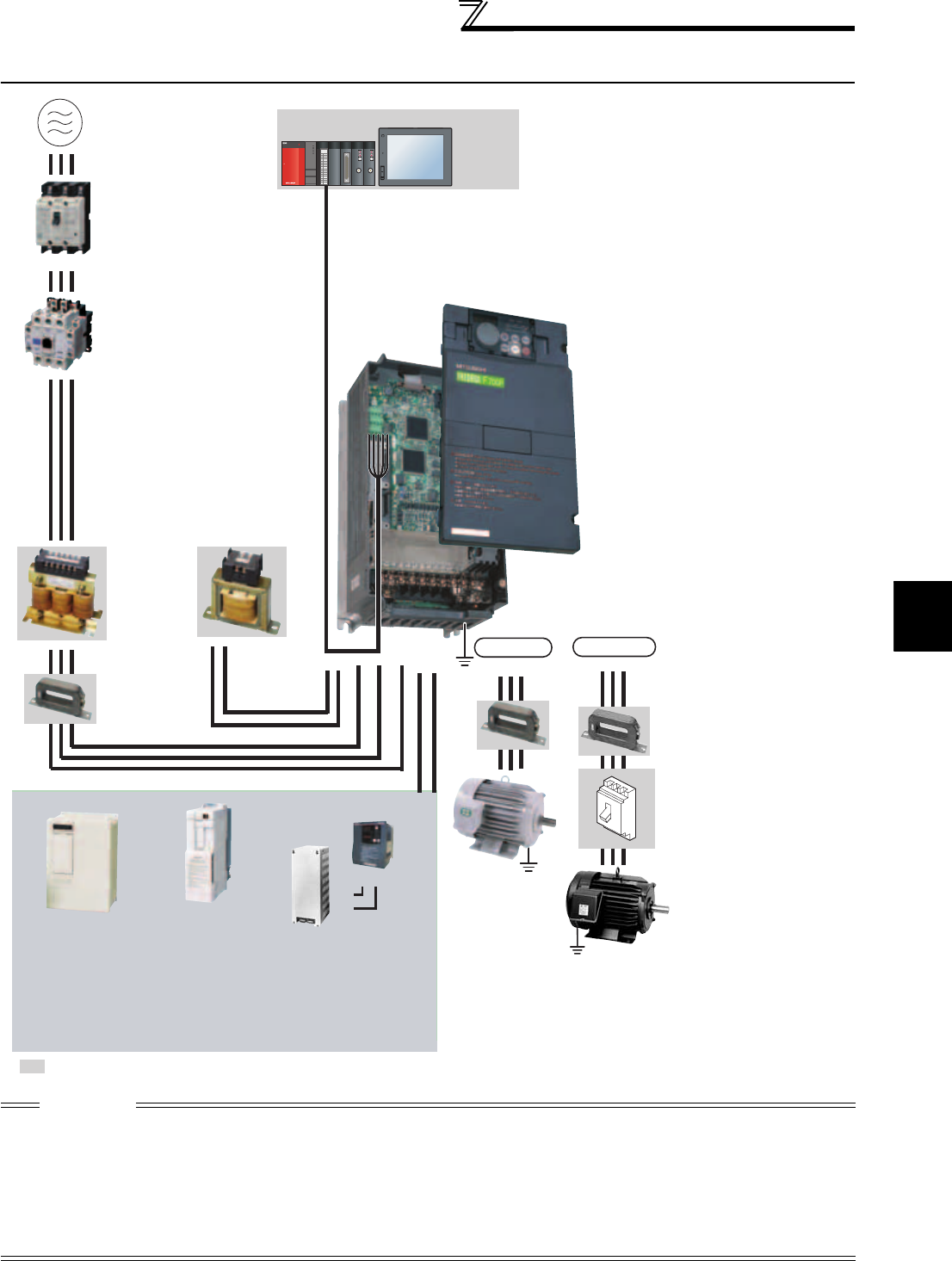

Inverter and peripheral devices

1

OUTLINE

1.2 Inverter and peripheral devices

CAUTION

· Do not install a power factor correction capacitor, surge suppressor or capacitor type filter on the inverter output side. This will

cause the inverter to trip or the capacitor, and surge suppressor to be damaged. If any of the above devices are connected,

immediately remove them.

· Electromagnetic wave interference

The input/output (main circuit) of the inverter includes high frequency components, which may interfere with the communication

devices (such as AM radios) used near the inverter. In this case, set the EMC filter valid to minimize interference.

(Refer to page 15.)

· Refer to the instruction manual of each option and peripheral devices for details of peripheral devices.

· An IPM motor cannot be driven by the commercial power supply.

U VW

: Install these options as required.

Power regeneration

common converter

(FR-CV

*1

)

Power regeneration

converter (MT-RC

*2

)

Resistor unit

(FR-BR

*1

, MT-BR5

*2

)

Brake unit

(FR-BU2, FR-BU

*1

, MT-BU5

*2

)

High power factor

converter

(FR-HC

*1

, MT-HC

*2

)

P/+

P/+

PR

PR

PULL

USB

MODE

RUN

ERR

USER

BAT

BOOT

PULL

POWER

RUN

T.PASS

SD

ERR

MNG

D.LINK

RD

ERR

RUN

T.PASS

SD

ERR

MNG

D.LINK

RD

ERR

Programmable

controller

Three-phase AC power supply

AC reactor

(FR-HAL)

DC reactor

(FR-HEL)

R/L1 S/L2 T/L3

P/+

N/-P/+

P1

UVW

Moulded case circuit

breaker (MCCB)

or earth leakage circuit

breaker (ELB), fuse

Magnetic contactor(MC)

RS-485 terminal block

EMC filter

(ferrite core)

(FR-BSF01, FR-BLF)

Devices connected

to the output

Use within the permissible power supply

specifications of the inverter.

The regeneration braking

capability of the inverter can be

exhibited fully.

Install this as required.

Install the magnetic contactor to ensure safety.

Do not use this magnetic contactor to start and stop

the inverter.

Doing so will cause the inverter life to be shortened.

The inverter can be connected with a

computer such as a programmable

controller and with GOT (human

machine interface).

They support Mitsubishi inverter

protocol and Modbus-RTU (binary)

protocol.

Do not install a power

factor correction capacitor,

surge suppressor or EMC filter (capacitor) on the

output side of the inverter.

When installing a moulded case circuit breaker on

the output side of the inverter, contact each

manufacturer for selection of the moulded case

circuit breaker.

Power supply harmonics

can be greatly suppressed.

Install this as required.

Greater braking capability

is obtained.

Install this as required.

The breaker must be selected carefully since

an in-rush current flows in the inverter at

power on.

Install an EMC filter (ferrite

core) to reduce the

electromagnetic noise

generated from the inverter.

Effective in the range from

about 0.5MHz to 5MHz.

A wire should be wound four

turns at a maximum.

General-

purpose

motor

Human machine interface

IM connection

IPM connection

Contactor

Example) No-fuse

switch (DSN type)

Install a contactor in an

application where the IPM

motor is driven by the load

even at power-OFF of the

inverter. Do not open or

close the contactor while

the inverter is running

(outputting).

Dedicated IPM motor

(MM-EFS, MM-EF)

Use the specified motor.

IPM motors cannot be driven

by the commercial power

supply.

Earth

(Ground)

Earth

(Ground)

Earth

(Ground)

Earth (Ground)

To prevent an electric shock, always earth

(ground) the motor and inverter.

Reactor (FR-HAL, FR-HEL)

Install reactors to suppress harmonics and to

improve the power factor. An AC reactor (FR-HAL)

(option) is required when installing the inverter near

a large power supply system (1000kVA or more).

The inverter may be damaged if you do not use

reactors.

Select the reactor according to the model.

For the 55K or lower, remove the jumpers across

terminals P/+ and P1 to connect to the DC reactor.

For the 75K or higher, a

DC reactor is supplied.

Always install the reactor.

*1 Compatible with the 55K or lower.

*2 Compatible with the 75K or higher.

EMC filter

(ferrite core)

(FR-BLF)

The 55K or lower has a built-in

common mode choke.

(Refer to page 346)

(Refer to page 4)

(Refer to page 4)

(Refer to page 4.)

Inverter (FR-F700P)

The life of the inverter is influenced by surrounding

air temperature. The surrounding air temperature

should be as low as possible within the permissible

range. Especially when mounting the inverter

inside an enclosure, take cautions of the

surrounding air temperature. (Refer to page 10)

Wrong wiring might lead to damage of the inverter.

The control signal lines must be kept fully away

from the main circuit to protect them from noise.

(Refer to page 14)

Refer to page 15 for the built-in EMC filter.

(Refer to page 359 and 360)

(Refer to page 52.)

(Refer to page 46.)

(Refer to page 38) (Refer to page 40 and 41)

(Refer to page 34)

(Refer to page 42)