341

Measurement of main circuit voltages,

currents and powers

6

PRECAUTIONS FOR MAINTENANCE AND INSPECTION

Measuring Points and Instruments

*1 Use an FFT to measure the output voltage accurately. A tester or general measuring instrument cannot measure accurately.

*2 When the carrier frequency exceeds 5kHz, do not use this instrument since using it may increase eddy-current losses produced in metal parts

inside the instrument, leading to burnout. If the wiring length between the inverter and motor is long, the instrument and CT may generate

heat due to line-to-line leakage current.

*3 When the setting of Pr. 195 ABC1 terminal function selection is positive logic

*4 A digital power meter (designed for inverter) can also be used to measure.

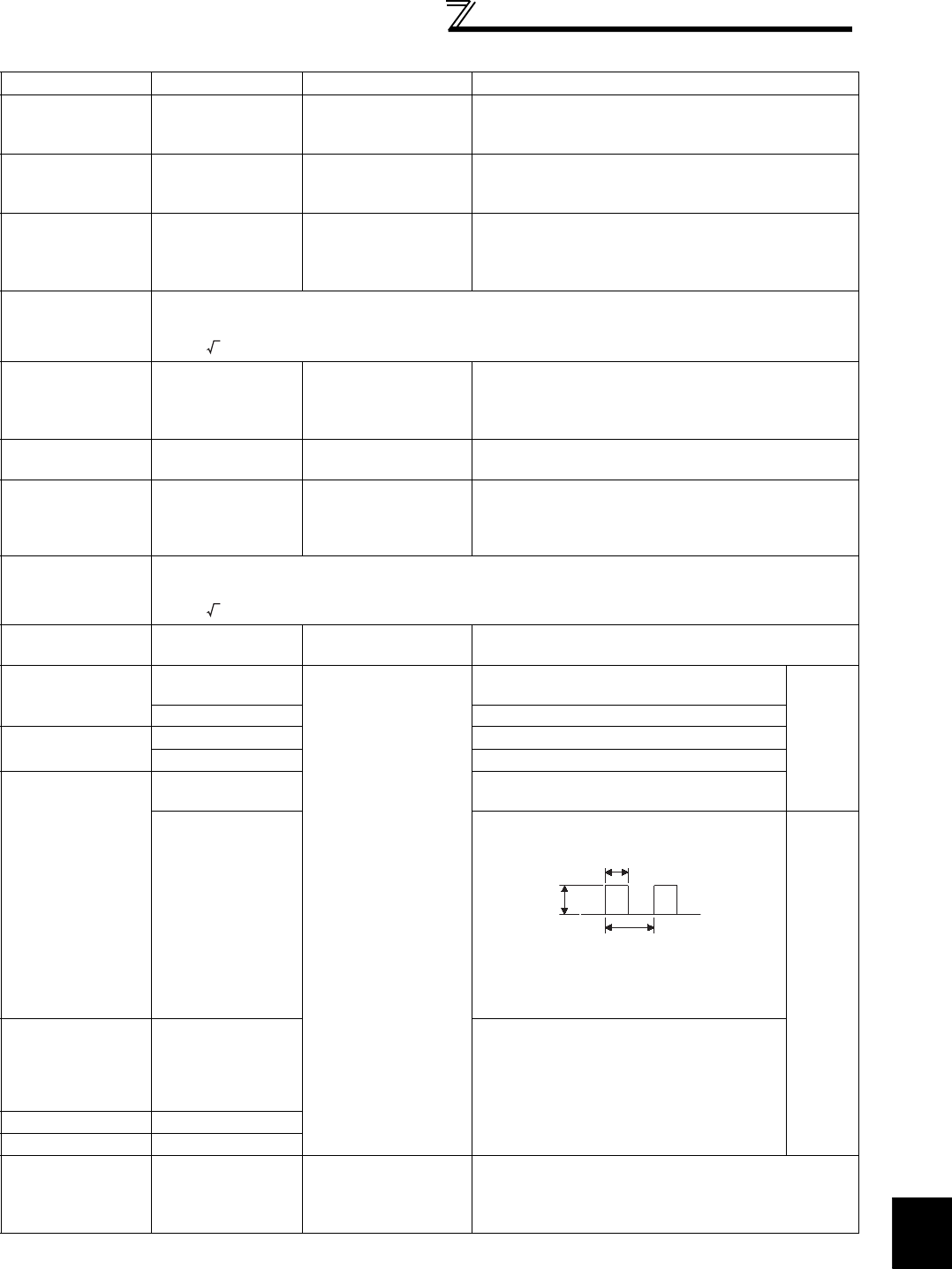

Item Measuring Point Measuring Instrument Remarks (Reference Measured Value)

Power supply voltage

V

1

Across R/L1 and S/L2,

S/L2 and T/L3,

T/L3 and R/L1

Moving-iron type AC

voltmeter

*4

Commercial power supply

Within permissible AC voltage fluctuation

Refer to page 346.

Power supply side

current

I

1

R/L1, S/L2, and T/L3

line currents

Moving-iron type AC

ammeter

*4

Power supply side

power

P1

R/L1, S/L2, T/L3 and

R/L1

and

S/L2,

S/L2

and

T/L3,

T/L3

and

R/L1

Digital power meter

(designed for inverter) or

e

lectrodynamic type

single-phase wattmeter

P1=W11+W12+W13 (3-wattmeter method)

Power supply side

power factor

Pf

1

Calculate after measuring power supply voltage, power supply side current and power supply side power.

Output side voltage

V

2

Across U and V,

V and W

and W and U

Rectifier type AC voltage

meter

*1 *4

(Moving-iron type cannot

measure)

Difference between the phases is within ±1% of the

maximum output voltage.

Output side current

I

2

U, V and W line

currents

Moving-iron type AC

ammeter

*2 *4

Difference between the phases is 10% or lower of the

rated inverter current.

Output side power

P

2

U, V, W and

U and V,

V and W

Digital power meter

(designed for inverter) or

e

lectrodynamic type

single-phase wattmeter

P2 = W21 + W22

2-wattmeter method (or 3-wattmeter method)

Output side power

factor

Pf2

Calculate in similar manner to power supply side power factor.

Converter output Across P/+ and N/−

Moving-coil type (such

as tester)

Inverter LED display is lit. 1.35

× V1

Frequency setting

signal

Across 2 and 5

Across 4(+) and 5

Moving-coil type

(Tester and such may be

used)

(Internal resistance:

50kΩ or larger)

0 to 10VDC, 4 to 20mA

"5" is

common

Across 1(+) and 5 0 to ±5VDC, 0 to ±10VDC

Frequency setting

power supply

Across 10 (+) and 5 5.2VDC

Across 10E(+) and 5 10VDC

Frequency meter

signal

Across AM(+) and 5

Approximately 10VDC at maximum frequency

(without frequency meter)

Across FM(+) and SD

Approximately 5VDC at maximum frequency

(without frequency meter)

Pulse width T1:

Adjusted by C0 (Pr. 900)

Pulse cycle T2: Set by Pr. 55

(Valid for frequency monitoring only)

"SD" is

common

Start signal

Select signal

Across SD and the

following:

STF, STR, RH, RM,

RL, JOG, RT, AU,

STOP, CS (+)

When open

20 to 30VDC

ON voltage: 1V or less

Reset

Across RES (+)

and

SD

Output stop

Across MRS (+)

and

SD

Fault signal

Across A1 and C1

Across B1 and C1

Moving-coil type

(such as tester)

Electric continuity check

*3

<Normal> <Fault>

Across A1 and C1 Discontinuity Continuity

Across B1 and C1 Continuity Discontinuity

Pf1 = ————— × 100%

P

1

3 V1 × I1

Pf2 = ————— × 100%

P

2

3 V2 × I2

8VDC

T1

T2