265

Special operation and frequency control

4

PARAMETERS

(4) I/O signals and parameter setting

⋅ Turn ON the X14 signal to perform PID control. When this signal is OFF, PID action is not performed and normal

inverter operation is performed. (However, turning X14 ON is not necessary when Pr.128 = "50, 51, 60, 61, 110,

111, 120, 121".)

⋅ Enter the set point across inverter terminals 2-5 or into Pr. 133 and enter the measured value signal across inverter

terminals 4 and 5. At this time, set any of "20, 21, 120, 121" in Pr. 128.

⋅ When entering the externally calculated deviation signal, enter it across terminals 1 and 5. At this time, set any of

"10, 11, 110, 111" in Pr. 128.

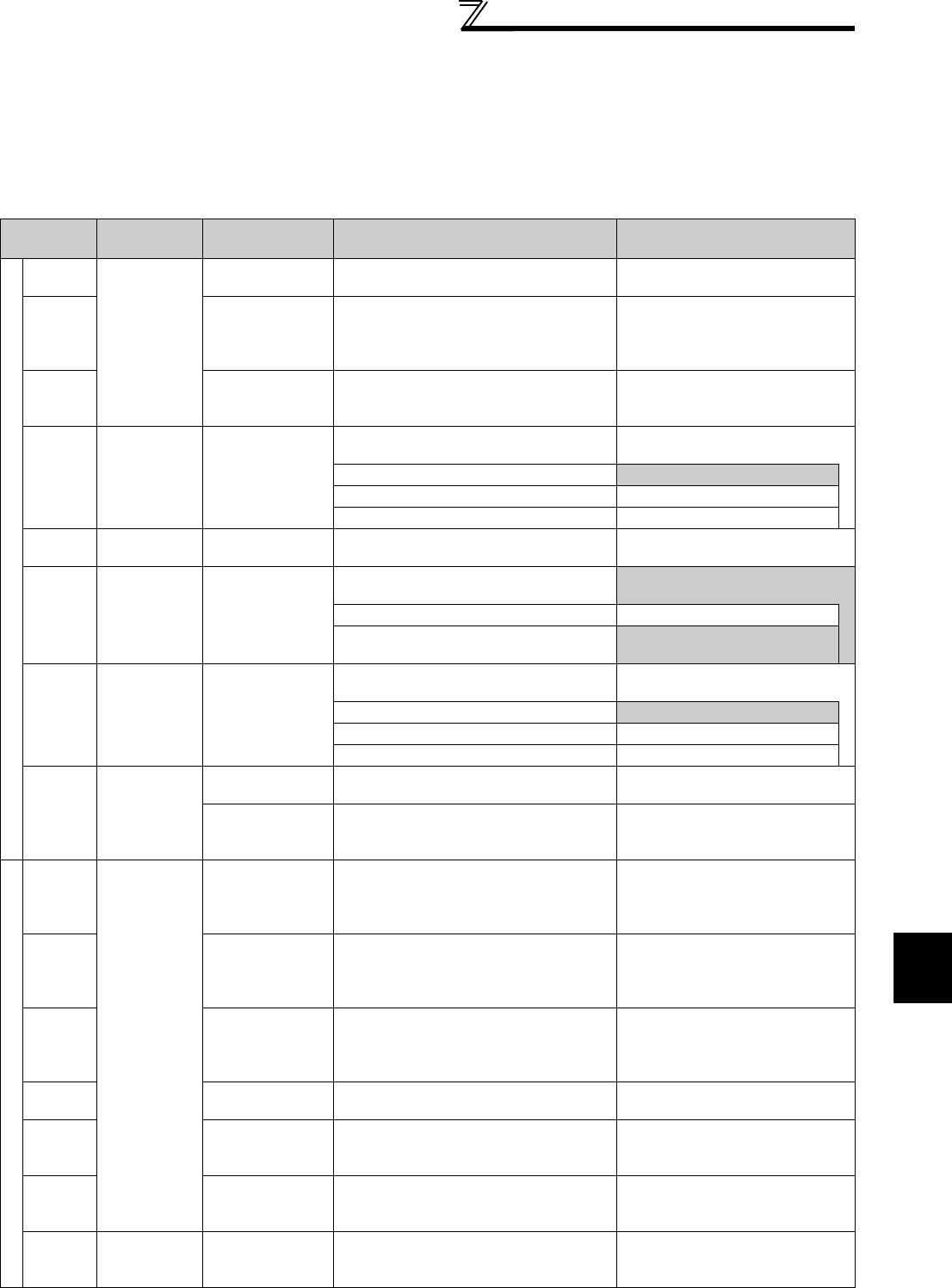

Signal

Terminal

Used

Function Description Parameter Setting

Input

X14

Depending on

Pr. 178 to Pr.

189

PID control

selection

Turn ON X14 to perform PID control. Set 14 in any of Pr. 178 to Pr. 189.

X64

PID forward/

reverse action

switchover

By turning ON X64, forward action can be

selected for PID reverse action (

Pr. 128

=

10, 20, 110, 120), and reverse action for

forward action (

Pr. 128

= 11, 21, 111, 121).

Set 64 in any of Pr. 178 to Pr. 189.

X72

PID integral value

reset

ON: Integral and differential values are

reset

OFF: Normal processing

Set 72 in any of Pr. 178 to Pr. 189.

22

*4 Set point input

Enter the set point for PID control.

Pr. 128 = 20, 21, 120, 121

Pr. 133 =9999

0 to 5V................0 to 100%

Pr. 73 = 1 *1, 3, 5, 11, 13, 15

0 to 10V..............0 to 100%

Pr. 73 = 0, 2, 4, 10, 12, 14

0 to 20mA...........0 to 100%

Pr. 73 = 6, 7, 16, 17

PU ⎯ Set point input

Set the set value (Pr. 133) from the

operation panel or parameter unit.

Pr. 128 = 20, 21, 120, 121

Pr. 133 = 0 to 100%

11

Deviation signal

input

Input the deviation signal calculated

externally.

Pr. 128 = 10 *1, 11, 110, 111

-5V to +5V..........-100% to +100%

Pr. 73 = 2, 3, 5, 7, 12, 13, 15, 17

-10V to +10V......-100% to +100%

Pr. 73 = 0, 1 *1, 4, 6, 10, 11, 14,

16

44

*4

Measured value

input

Input the signal from the detector

(measured value signal).

Pr. 128 = 20, 21, 120, 121

4 to 20mA...........0 to 100%

Pr. 267 = 0 *1

1 to 5V................0 to 100%

Pr. 267 = 1

2 to 10V..............0 to 100%

Pr. 267 = 2

Communi-

cation

*2

⎯

Deviation value

input

Input the deviation value from L

ON

W

ORKS

,

CC-Link communication.

Pr. 128 = 50, 51

Set value,

measured value

input

Input the set value and measured value

from L

ONWORKS , CC-Link

communication.

Pr. 128 = 60, 61

Output

FUP

Depending on

Pr. 190 to Pr.

196

Upper limit output

Output to indicate that the measured

value signal exceeded the upper limit

value (Pr. 131).

Pr. 128 =20, 21, 60, 61, 120, 121

Pr. 131 ≠ 9999

Set 15 or 115 in any of Pr. 190 to Pr.

196.

*3

FDN Lower limit output

Output when the measured value signal

falls below the lower limit (Pr. 132).

Pr. 128 =20, 21, 60, 61, 120, 121

Pr. 132 ≠ 9999

Set 14 or 114 in any of Pr. 190 to Pr.

196.

*3

RL

Forward (reverse)

rotation direction

output

"Hi" is output to indicate that the output

indication of the parameter unit is forward

rotation (FWD), and "Low" to indicate that

it is reverse rotation (REV) or stop (STOP).

Set 16 or 116 in any of Pr. 190 to Pr.

196.

*3

PID

During PID

control activated

Turns ON during PID control.

Set 47 or 147 in any of Pr. 190 to Pr.

196.

*3

SLEEP

PID output

interruption

Turns ON when the PID output

interruption function is performed.

Pr. 575 ≠ 9999

Set 70 or 170 in any of Pr. 190 to Pr.

196.

*3

Y48 PID deviation limit

Output when the absolute value of

deviation exceeds the limit value.

Pr. 553 ≠ 9999

Set 48 or 148 in any of Pr. 190 to Pr.

196.

*3

SE SE

Output terminal

common

Common terminal for terminals assigned

to FUP signal, FDN signal, RL signal, PID

signal, SLEEP signal, and Y48 signal