15

Input Terminals

1

INSTALLATION AND WIRING

1.8 Input Terminals

1.8.1 Run (start) and stop (STF, STR)

To start and stop the motor, first switch on the input power supply of the inverter

(switch on the magnetic contactor, if any, in the input circuit during preparation for

operation), then start the motor with the forward or reverse rotation start signal.

POINT

With "1" factory-set in Pr. 507 "inverter operation lock mode setting", the start

signal is not enabled unless the SQ signal is on.

Set "0" in Pr. 507 when performing inverter operation only.

(Refer to page 138 for Pr. 507.)

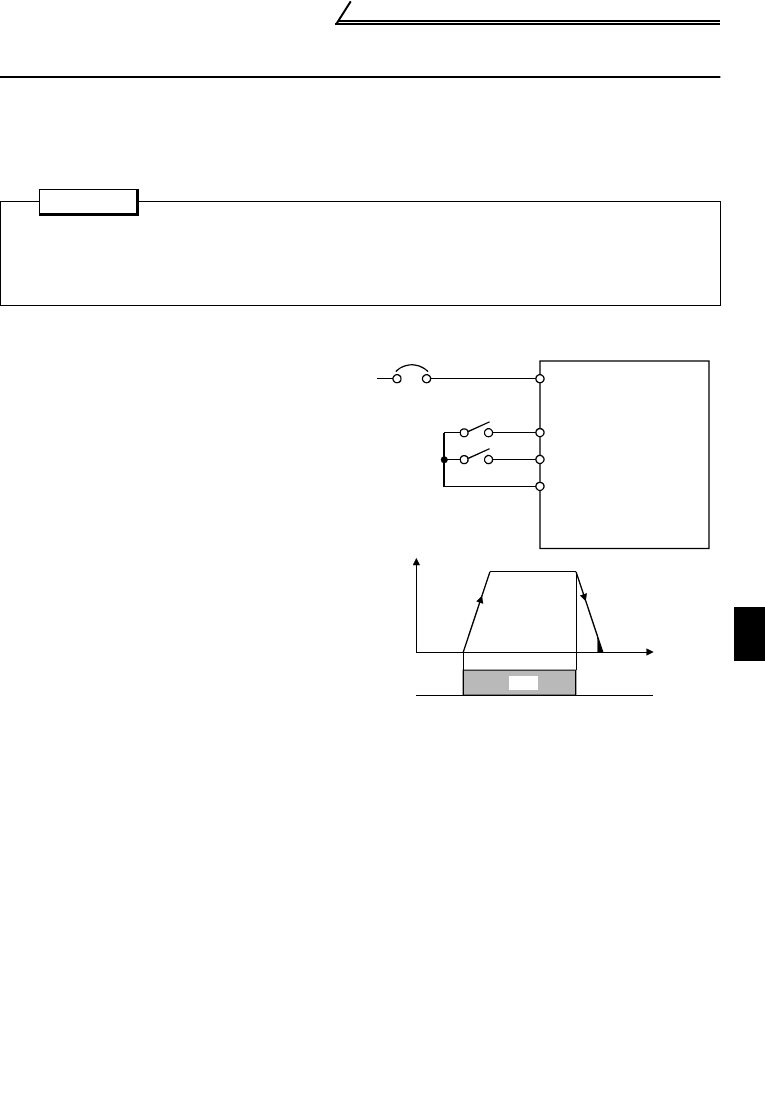

(1) STF, STR

A connection is shown on the right.

1) The forward/reverse rotation signal is

used as both the start and stop signals.

Switch on either of the forward and

reverse rotation signals to start the

motor in the corresponding direction.

Switch on both or switch off the start

signal during operation to decelerate

the inverter to a stop.

2) The frequency setting signal may be

given by setting the required values in

Pr. 4 to Pr. 6 "three-speed setting"

(high, middle, low speeds), by setting

using a sequence ladder, or by setting

from CC-Link. (For three-speed

operation, refer to page 17.)

Connection Example

3) After the start signal has been input, the inverter starts operating when the frequency setting

signal reaches or exceeds the "starting frequency" set in Pr. 13 (factory-set to 0.5Hz).

If the motor load torque is large or the "torque boost" set in Pr. 0 is small, the inverter may be

overloaded due to insufficient torque.

If the "minimum frequency" set in Pr. 2 (factory setting = 0Hz) is 6Hz, for example, merely

entering the start signal causes the running frequency to reach the minimum frequency of 6Hz

according to the "acceleration time" set in Pr. 7.

4) To stop the motor, operate the DC injection brake for the period of "DC injection brake

operation time" set in Pr. 11 (factory setting = 0.5s) at not more than the DC injection brake

operation frequency or at not more than 0.5Hz.

To disable the DC injection brake function, set 0 in either of Pr. 11 "DC injection brake

operation time" and Pr. 12 "DC injection brake voltage".

In this case, the motor is coated to a stop at not more than the frequency set in Pr. 10 "DC

injection brake operation frequency" (0 to 120Hz variable) or at not more than 0.5Hz (when

the DC injection brake is not operated).

5) If the reverse rotation signal is input during forward rotation or the forward rotation signal is

input during reverse rotation, the inverter is decelerated and then switched to the opposite

output polarity without going through the stop mode.

NFB

R,S,T

Inverter

STF (Pr.65="17")

STR (Pr.63="9999")

SD

ON

Power

supply

Forward

rotation start

Reverse

rotation start

Output frequency

Across STF-SD

(STR)

Time