12

Reference Manual

IP2048/RM, Rev AA

Section 3: Installation

February 2015

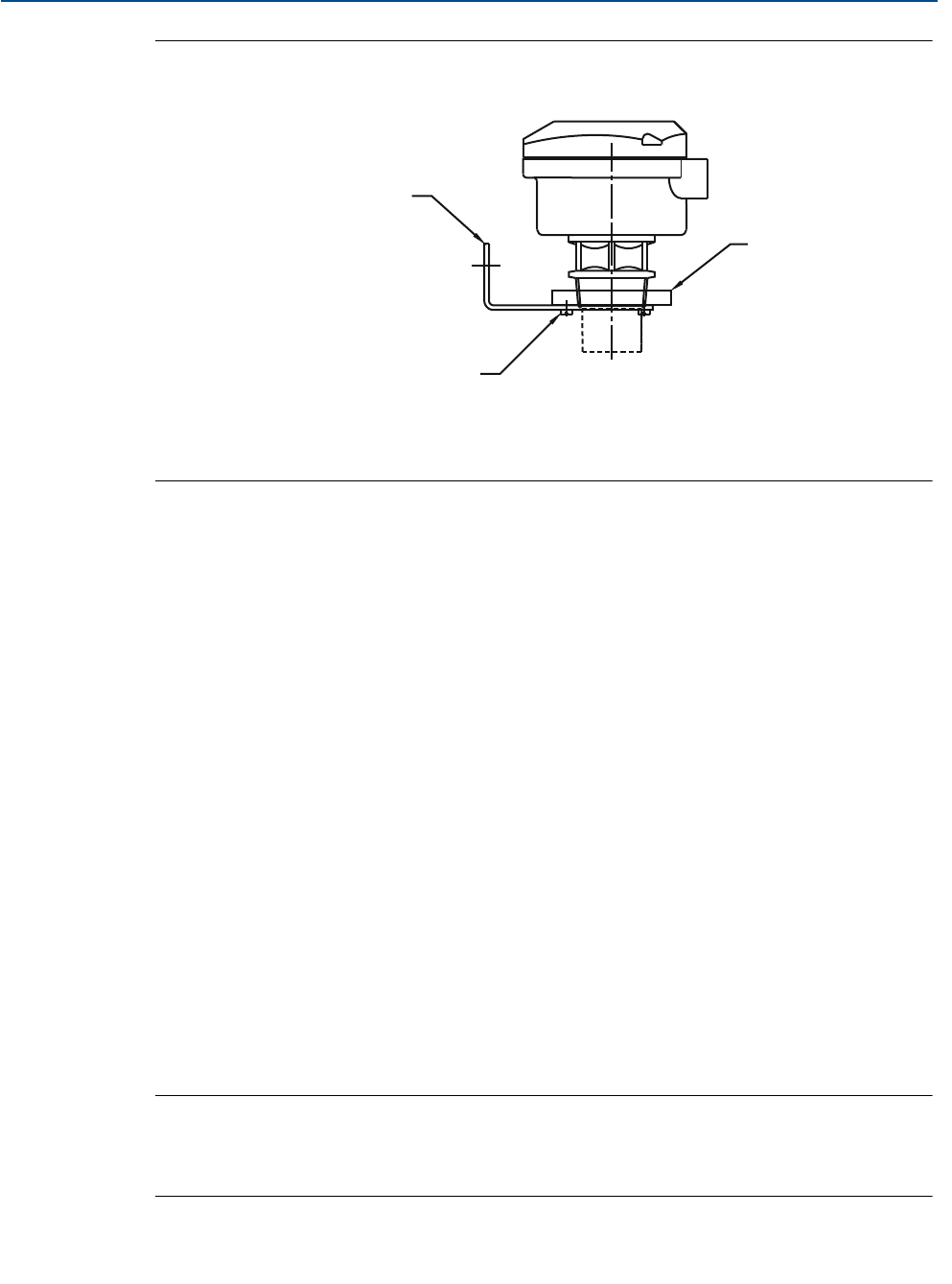

Figure 3-2. Mounting the transmitter using a bracket kit

A. Stainless steel bracket

B. No. 4X 13 long self tap screw (3 positions), carbon steel (zinc plated)

C. PVC disc

Installing in a tank with a nozzle or stand-off

Installation procedure

1. Use PTFE tape on the screw thread of the transmitter (Figure 3-3).

2. If the tank has a flanged nozzle or stand-off:

a. Attach the transmitter to a non-metal instrument flange using the threaded

connection. Tighten to a torque of 1.5 lb-ft (2 N-m) using the transmitter’s hexagon.

b. The instrument (accessory) flanges supplied by Emerson Process Management are

manufactured from PVC and are a full face design. Care must be taken when installing

to a raised face mating flange on the tank or vessel to prevent distortion of the PVC

flange by over-tightening the bolts.

c. Ensure the gasket is sitting correctly on the tank flange.

d. Lower the assembled transmitter and instrument flange onto the tank flange, and

secure with appropriate bolting to a suitable torque for the flanges.

If mating to a raised face flange (RF) on the tank nozzle or stand-off, tighten to a

maximum torque of 10 lb-ft (13.6 N-m).

3. If the tank has a threaded nozzle or stand-off:

a. Attach the transmitter to the nozzle/stand-off using the threaded connection.

b. Tighten to a torque of 1.5 lb-ft (2 N-m) using the transmitter’s hexagon.

Note

If the transmitter face does not protrude into the vessel, note the dimensions in

Table 3-1 on page 3-13 for Figure 3-3, and ensure that the nozzle/vessel weld is smooth

and free from internal weld beads or other projections.

B

C

A

Note: Combined weight of bracket

and disc is 16 oz (0,5 kg).