Chapter 4 Explanation of Functions

4 - 65

4.2.64 Over-torque signal (OTQ)

The inverter outputs the over-torque signal when it detects

that the estimated motor output torque exceeds the

specified level.

To enable this function, assign function "07" (OTQ:

over-torque signal) to an intelligent output terminal.

This function is effective only when the V/F characteristic curve selection selected with function "A044" or

"A244" is the sensorless vector control, 0Hz-range sensorless vector control, or vector control with sensor.

With any other V/F characteristic curve selection, the output of the OTQ signal is unpredictable.

When using the inverter for a lift, use the OTQ signal as the trigger to stop braking. Use the

frequency-arrival signal as the trigger to start braking.

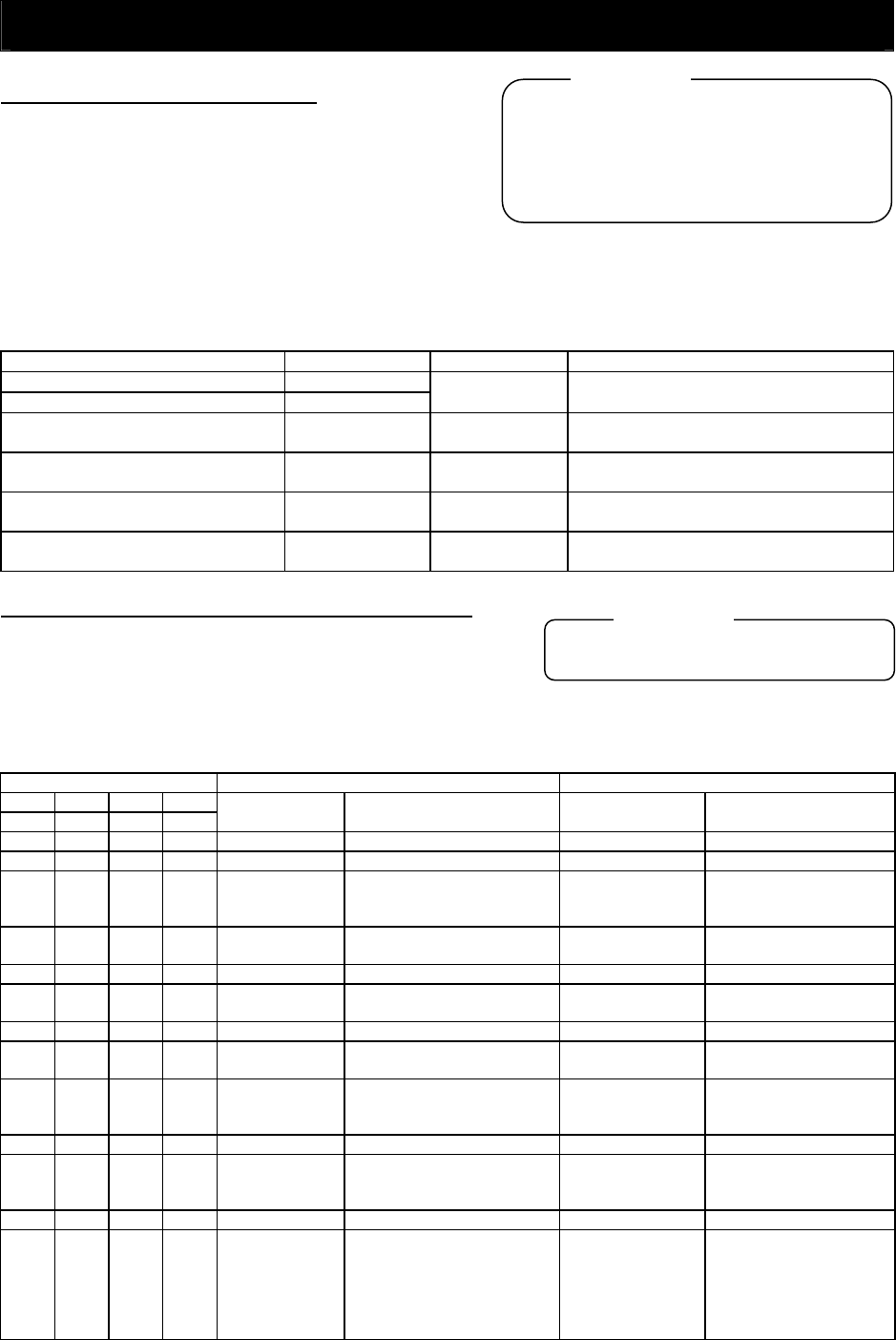

Item Function code Set value Description

Terminal function C021 to C025

Alarm relay terminal function C026

07 OTQ: Over-torque signal

Over-torque (forward-driving) level

setting

C055 0. to 200. (%)

Threshold level to output the OTQ signal

during forward powering operation

Over-torque (reverse

regenerating) level setting

C056 0. to 200. (%)

Threshold level to output the OTQ signal

during reverse regeneration operation

Over-torque (reverse driving) level

setting

C057 0. to 200. (%)

Threshold level to output the OTQ signal

during reverse powering operation

Over-torque (forward

regenerating) level setting

C058 0. to 200. (%)

Threshold level to output the OTQ signal

during forward regeneration operation

4.2.65 Alarm code output function (AC0 to AC3)

The alarm code output function allows you to make the inverter

output a 3- or 4-bit code signal as the trip factor when it has

tripped.

Specifying "01" (3 bits) or "02" (4 bits) for the alarm code output (C062) forcibly assigns the alarm code

output function to intelligent output terminals [11] to [13] or [11] to [14], respectively.

The following table lists the alarm codes that can be output:

Intelligent output terminals When "4 bits" is selected When "3 bits" is selected

14 13 12 11

AC3 AC2 AC1 AC0

Factor code Cause of tripping Factor code Cause of tripping

0 0 0 0 Normal Normal operation Normal Normal

0 0 0 1 E01 to E03,E04 Overcurrent protection E01 to E03, E04 Overcurrent protection

0 0 1 0 E05, E38

Overload protection

Low-speed overload

protection

E05

Overload protection

Low-speed overload

protection

0 0 1 1 E07, E15

Overvoltage/input

overvoltage protection

E07, E15

Overvoltage/input

overvoltage protection

0 1 0 0 E09 Undervoltage protection E09 Undervoltage protection

0 1 0 1 E16

Instantaneous power failure

protection

E16

Instantaneous power

failure protection

0 1 1 0 E30 IGBT error E30 IGBT error

0 1 1 1 E06

Braking resistor overload

protection

- Other error

1 0 0 0

E08, E11, E23

E25

EEPROM, CPU, GA

communication, or main

circuit error

- -

1 0 0 1 E10 CT error - -

1 0 1 0

E12, E13, E35,

E36

External trip, USP error,

thermistor error, or braking

error

- -

1 0 1 1 E14 Ground-fault protection - -

1 1 0 0 E43, E44, E45

Invalid instruction in easy

sequence

Nesting error in easy

sequence

Easy sequence execution

command error

- -

A044/A244/A344: V/F characteristic curve selection,

1st/2nd/3rd motors

C021 to C025: Terminal [11] to [15] functions

C055: Over-torque (forward-driving) level setting

C056: Over-torque (reverse regenerating) level setting

C057: Over-torque (reverse driving) level setting

C058: Over-torque (forward regenerating) level setting

Related code

C021 to C025: Terminal [11] to [15] functions

C062: Alarm code output

Related code