Reference Manual

00809-0100-4530, Rev BA

July 2009

C-15

Rosemount 5300 Series

DYNAMIC VAPOR

COMPENSATION

Rosemount 5300 Series is based on the Time Domain Reflectometry (TDR)

technology where low power nanosecond microwave pulses are guided down

a probe submerged in the process media. When a radar pulse reaches a

media with a different dielectric constant, part of the energy is reflected to the

transmitter. The time difference between the transmitted pulse and the

reflected pulse is converted into a distance from which the total level or

interface level is calculated.

For radar level gauging, the actual measured quantity is the propagation time

through the empty space between the radar level transmitter and the liquid

surface. For typical radar level transmitter accuracy, the propagation speed of

the radar signal should be close to the velocity of light in vacuum. However, in

some important cases, the deviation is not negligible and must be taken into

account for accuracy. High tank pressure in combination with certain gases is

an example.

High pressure water steam can influence radar level transmitter

measurements. This is due to the high pressure as well as the polar structure

of water molecules. In such cases, the Rosemount 5300 Series Level

transmitter can be configured for compensation for this effect.

Water has high critical temperature and pressure (705 ºF / 374 ºC and

140 bar, respectively). Level measurement may not be possible above these

limits. However, some applications, such as power plants, may use water

near the limits. In a closed vessel containing water liquid and water vapor,

existing databases (referred to as a Mollier diagram) have been used to

calculate pressure and vapor density, and deduce the dielectric constant of

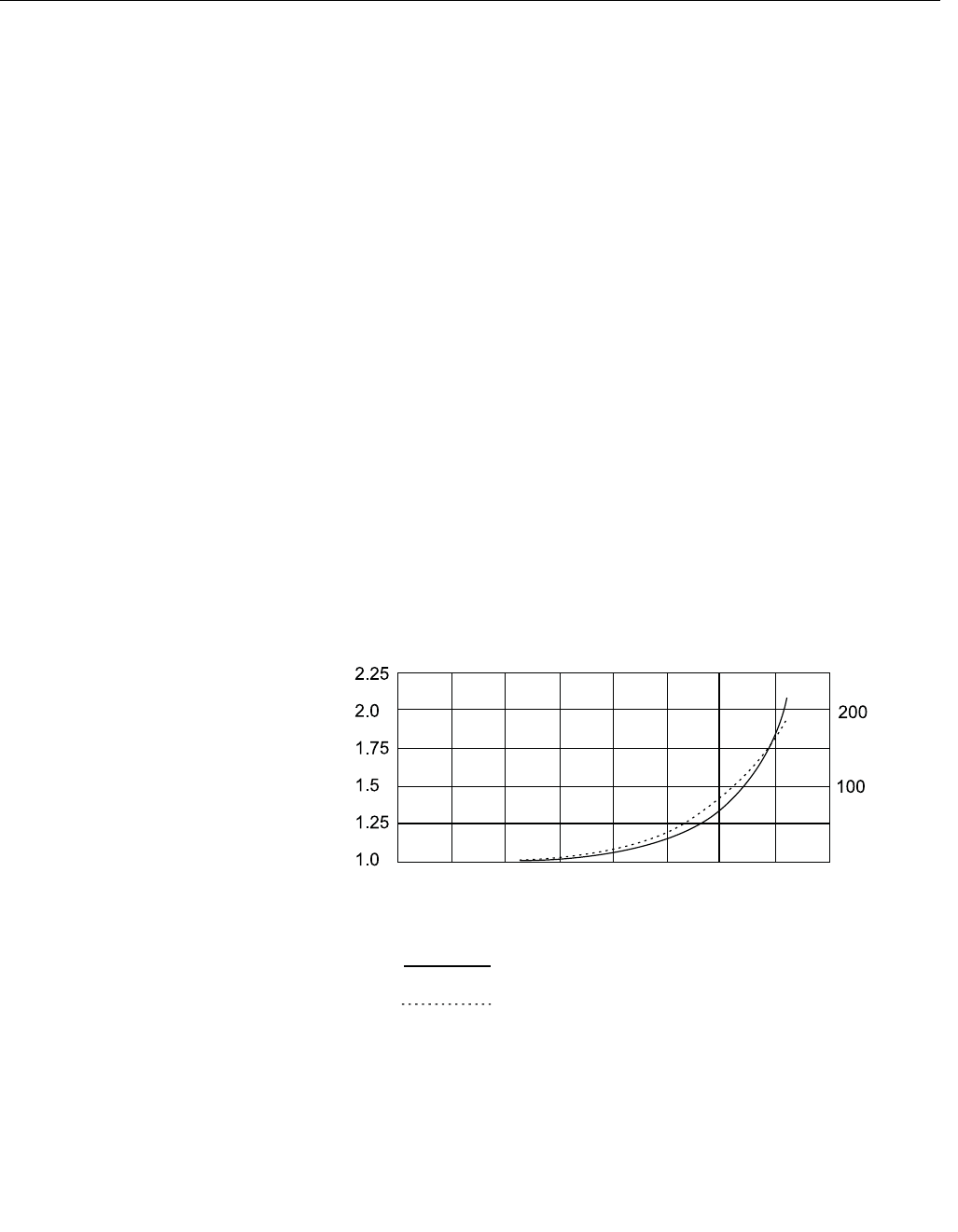

the vapor from this. The dielectric constant changes as given in Figure C-12.

Figure C-12. Dielectric constant

versus temperature for

saturated water vapor.

The standard version of a Rosemount 5300 Series level transmitter can be

configured for static compensation of vapor by manually entering the

dielectric constant of vapor, see “Dielectric Constant Settings” on page C-14.

For applications with a varying pressure and/or temperature, certain models

of the Rosemount 5300 Series have a built-in function (Dynamic Vapor

Compensation) that automatically compensates for varying vapor dielectric

constants.

32 (0) 212 (100)

392 (200)

572 (300) 752 (400)32 (0) 212 (100)

392 (200)

572 (300) 752 (400)32 (0) 212 (100)

392 (200)

572 (300) 752 (400)

Pressure (Bar)

Dielectric constant

32 (0) 212 (100)

392 (200)

572 (300) 752 (400)

Temperature (

o

F/

o

C)

Dielectric constant

Pressure