Overview

3A2098H 13

Overview

System Overview

The PCF fluid metering system combines closed-loop

pressure control with the ability to change bead profiles

quickly. When used with an optional flow meter, the sys-

tem automatically adjusts for fluctuations in the operat-

ing environment, such as material viscosity,

temperature and tip wear, in order to maintain the

desired dispense rate. The module responds to automa-

tion signals to provide an accurate and consistent output

flow based on a comparison of actual to desired flow

rates.

Typical Applications

• Bead dispensing

• Gasketing

• Seam sealing

• Hem flange

• Sound deadening

• Anti-flutter

• Body panel reinforcement

• Profile wrapping

• Cable filling

System Components

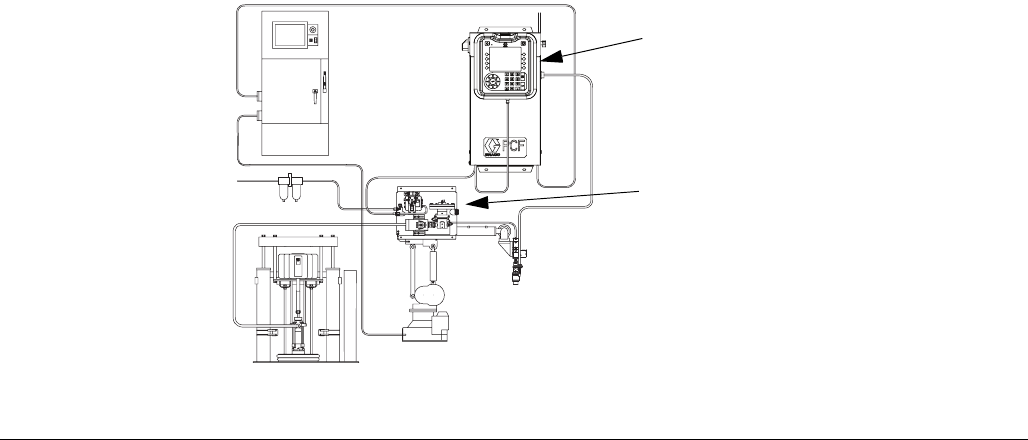

The diagram in F

IG

. 4 shows an example of the PCF

module and cables.

Control Center (User Interface)

The control center communicates with the PCF fluid

plate assembly to control fluid pressure and dispense

valve operation.

The control center receives input from the automation

controller, and uses these inputs to determine communi-

cation to the fluid plate assembly.

Fluid Plate Assembly

The fluid plate assembly contains components that con-

trol and monitor fluid dispensing. A PCF fluid metering

system can have up to four fluid plates. Each fluid plate

can control up to four dispense valves. The system sup-

ports up to 16 dispense valves and can simultaneously

dispense from up to 10 dispense valves.

PrecisionSwirl Orbital Dispenser

(Swirl Dispenser), Sold Separately

The swirl dispenser dispenses material in a circular pat-

tern at speeds from 6600 to 24000 rpm. A PCF fluid

metering system can have up to four swirl dispensers.

See manual 309403 for detailed information.

F

IG

. 4: PCF System Components

System shown with one fluid plate and one swirl dispenser

Control Center

(User Interface)

Fluid Plate Assembly