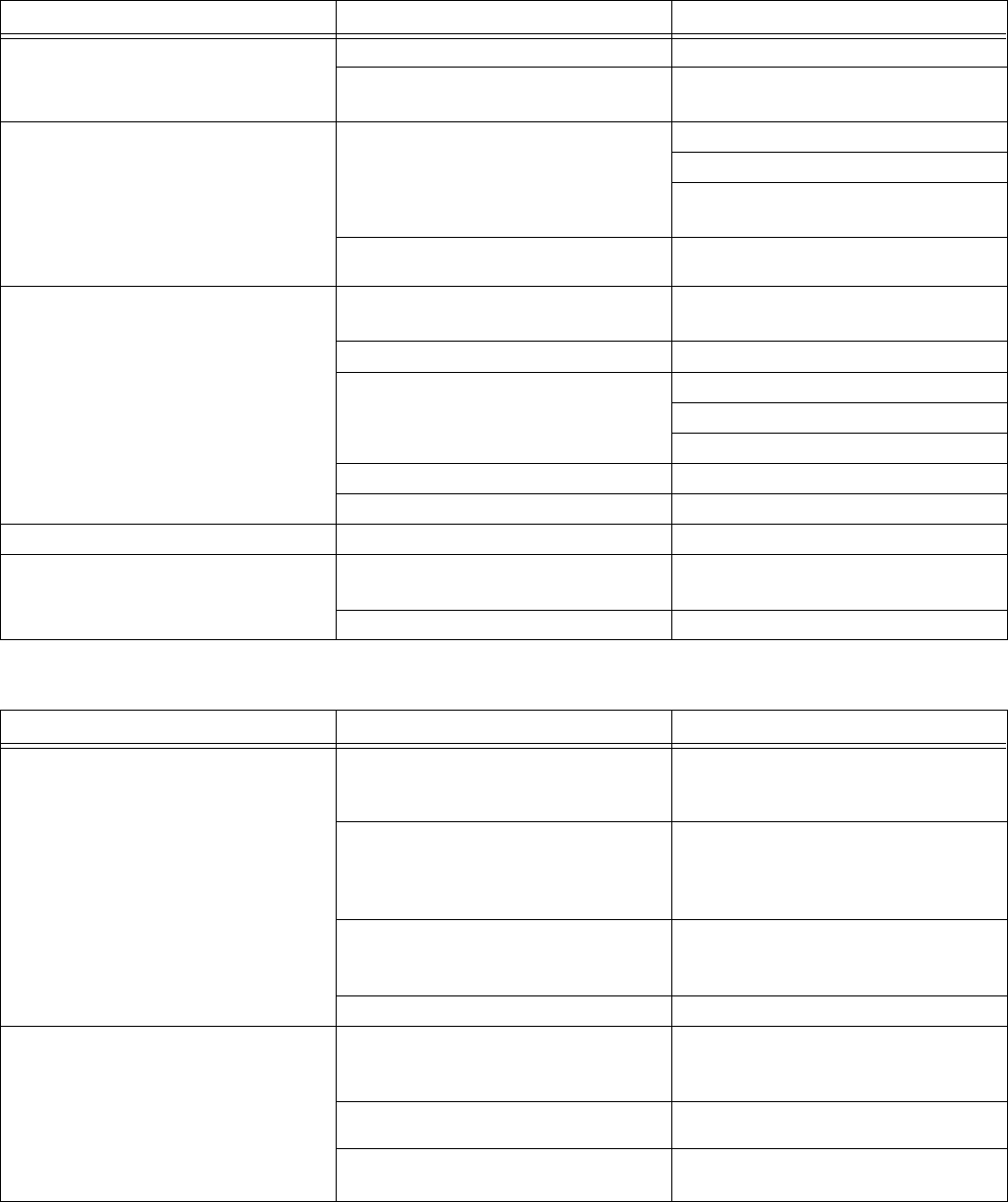

Troubleshooting

64 3A2098H

Dispense Valves

Swirl Dispenser

Problem Cause Solution

Valve not opening Air not getting to the open port Verify air pressure to solenoid

No “Valve On” signal from automa-

tion unit

Check input from automation unit

Valve not shutting off Air not getting to the close port

(except AutoPlus valve)

Verify air pressure to solenoid

Verify solenoid operation

Verify air line routing and connec-

tions

“Valve On” signal from automation

unit is on

Check input from automation unit

Sluggish open/close Air pressure low Verify air pressure is above 60 psi

(410 kPa, 4.1 bar)

Needle/seat worn Rebuild valve; replace needle/seat

Pressurized material past the valve

shut-off is escaping

Reduce running pressure

Reduce nozzle length

Increase nozzle orifice size

Faulty solenoid valve Replace solenoid valve

Solenoid valve muffler restricted Clean or replace muffler

Material leaks from back of valve Shaft seal is worn Rebuild valve; replace seals

Air leaks from dispense valve Loose air connections Check air connections; tighten if

necessary

Worn piston o-ring Rebuild valve; replace piston o-ring

Problem Cause Solution

Motor not running (motor fault alarm

active)

Cable disconnected Verify cable connections to swirl

board, swirl motor cable, and swirl

orbiter

CAN cable was re-connected with

system power on (amber LED on

swirl board will be on, this indicates

circuit protection was triggered)

Cycle system power

Shorted motor cable (amber LED on

swirl board will be on, this indicates

circuit protection was triggered)

Replace swirl motor cable (55 ft)

then cycle power

Faulty swirl orbiter Replace swirl orbiter

Motor not running (motor fault alarm

not active)

Cable disconnected

Verify cable connections to swirl

board, swirl board power cable, and

swirl control DGM

No “Swirl Enable” signal from auto-

mation unit

Check input from automation unit

Swirl not installed

Verify that the proper swirl orbiter is

installed in the system setup screen