Chapter 10 Adjustment

10–3

10-2 Gain adjustment

10-2-1 Current loop gain

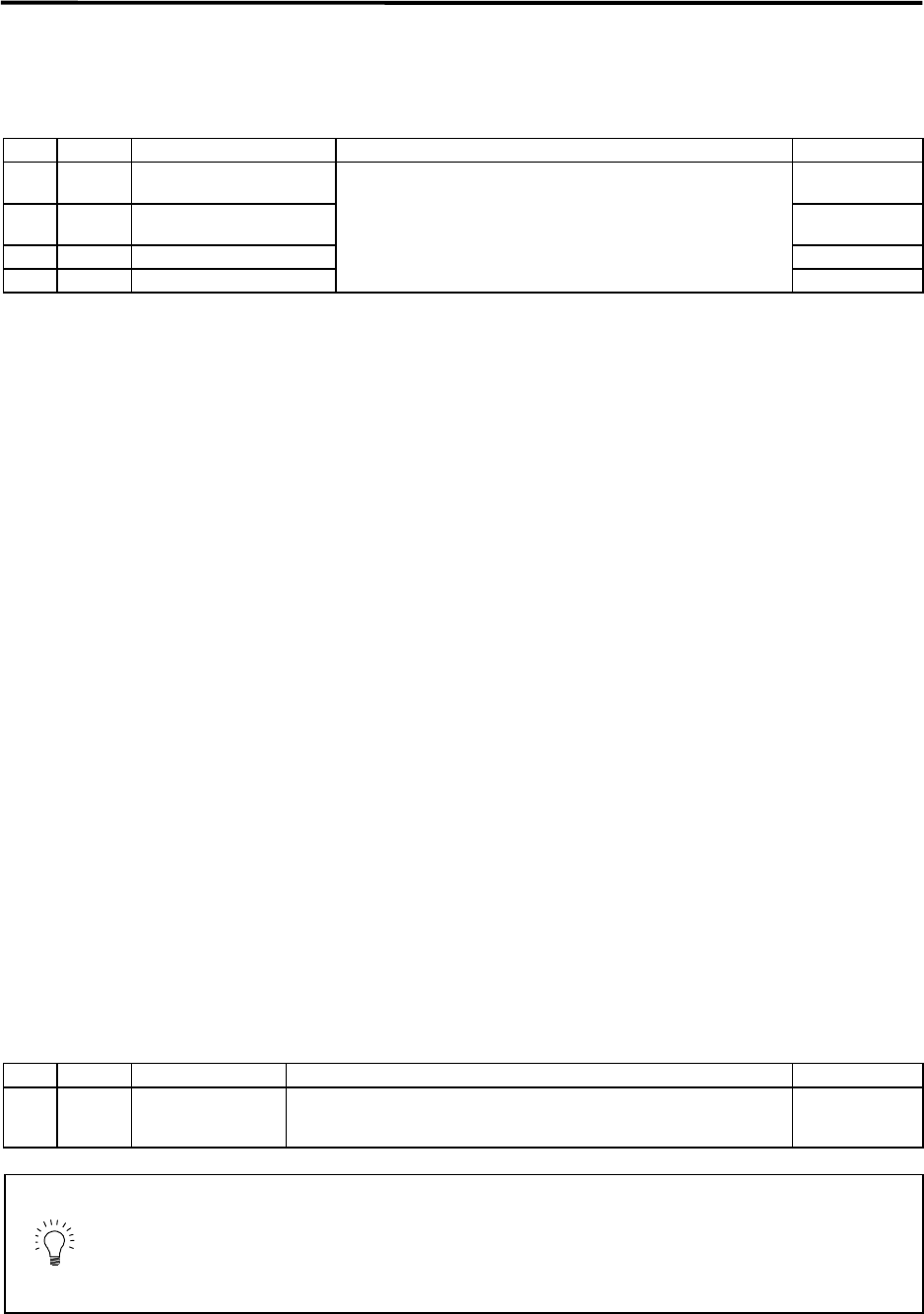

No. Abbrev. Parameter name Explanation Setting range

SV009 IQA Current loop q axis leading

compensation

1 to 20480

SV010 IDA Current loop d axis leading

compensation

1 to 20480

SV011 IQG Current loop q axis gain 1 to 4096

SV012 IDG Current loop d axis gain

This setting is determined by the motor's electrical

characteristics.

Basically set the standard parameters for all parameters.

(These are used for maker adjustments.)

1 to 4096

10-2-2 Speed loop gain

(1) Setting the speed loop gain

The speed loop gain (SV005: VGN1) is an important parameter for determining the

responsiveness of the servo control. During servo adjustment, the highest extent that this value

can be set to becomes important. The setting value has a large influence on the machine

cutting precision and cycle time.

To adjust the VGN1 value, first obtain the standard VGN1 to judge how much VGN1 is

required for the machine total movable mass. The standard VGN1 differs according to the

size of the machine's movable mass. Refer to the section "9-2-3 Parameters set according

to machine movable mass".

<When machine resonance does not occur at the standard VGN1>

Set the standard VGN1. Use the standard value if no problem (such as machine resonance)

occurs. If sufficient cutting precision cannot be obtained at the standard VGN1, VGN1 can be

raised above the standard value if a 70 percent margin is maintained in respect to the machine

resonance's occurrence limit. The cutting accuracy can also be improved by adjusting with the

disturbance observer.

<When machine resonance occurs at the standard VGN1>

Machine resonance is occurring if the shaft makes abnormal sounds when operating or

stopping, and a fine vibration can be felt when the machine is touched while stopped. Machine

resonance occurs because the servo control responsiveness includes the machine resonance

points. Machine resonance can be suppressed by lowering VGN1 and the servo control

responsiveness, but the cutting precision and cycle time are sacrificed. Thus, set a vibration

suppression filter and suppress the machine resonance (Refer to section "10-3-2 Vibration

suppression measures"), and set a value as close as possible to the standard VGN1. If the

machine resonance cannot be sufficiently eliminated even by using a vibration suppression filter,

then lower the VGN1.

No. Abbrev. Parameter name Explanation Setting range

SV005 VGN1 Speed loop gain Set this according to the movable mass size.

If resonance occurs, adjust by lower the setting by 20% to 30% at a

time.

1 to 999

POINT

The final VGN1 setting value should be 70 to 80% of the largest value at which

machine resonance does not occur.

If the vibration suppression functions are used to suppress the resonance and

the VGN1 setting value is raised, the subsequent servo adjustment becomes

more favorable.