Chapter 10 Adjustment

10–13

(2) Adjusting the speed loop leading compensation (VIA)

The VIA has a large influence on the position trackability, particularly during high-speed cutting

(generally F1000 or more). Raising the setting value improves the position trackability, and the

contour precision during high-speed cutting can be improved. For high-speed high-precision

cutting machines, adjust so that a value equal to or higher than the standard value can be set.

When the VIA is set lower than the standard value and set to a value differing between

interpolation axes, the roundness precision may become worse (the circle may distort). This is

due to differences occurring in the position trackability between interpolation axes. The distortion

can be improved by matching the VIA with the smaller of the values. Note that because the

position trackability is not improved, the surface precision will not be improved.

(Refer to "10-2-2 (2) Setting the speed loop leading compensation")

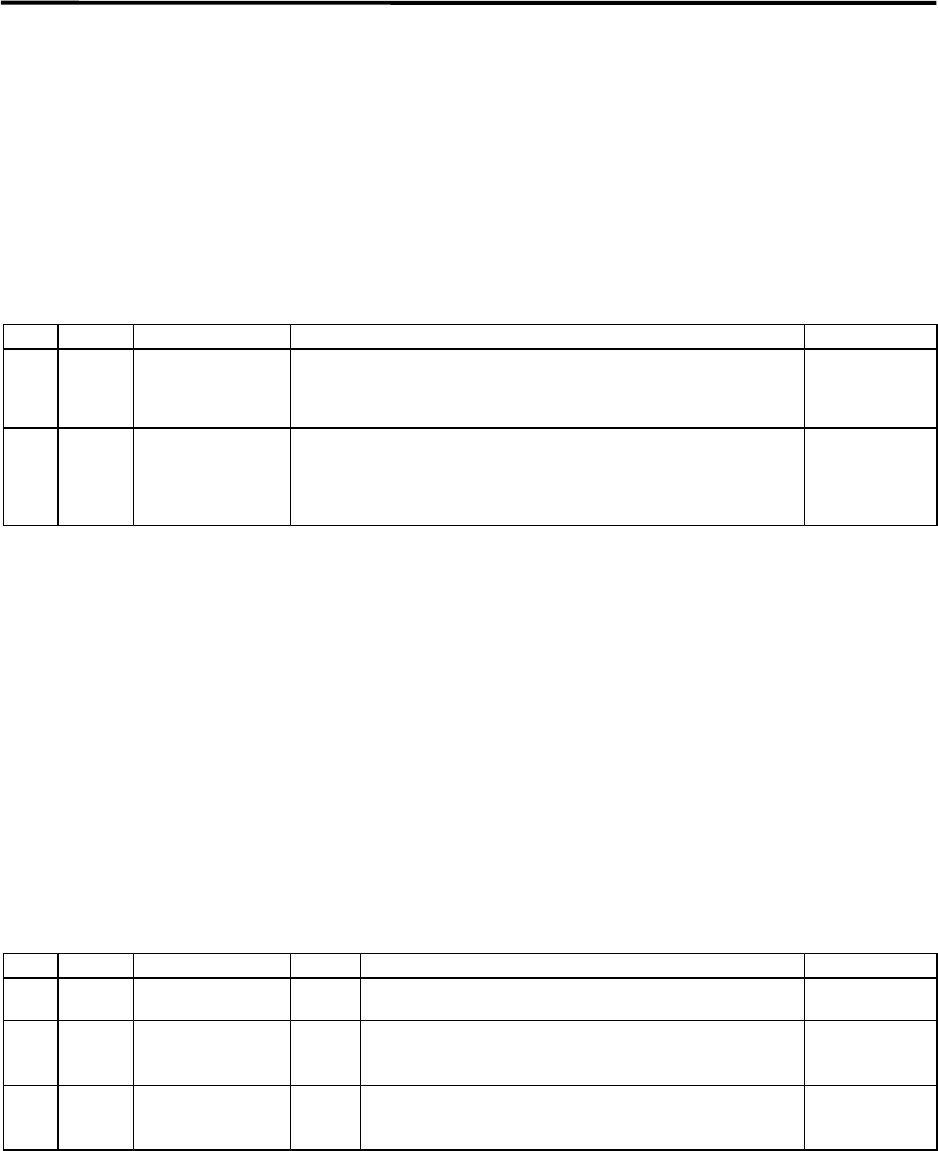

No. Abbrev. Parameter name Explanation Setting range

SV005 VGN1 Speed loop gain

Increase the value by 10 to 20% at a time.

If the machine starts resonating, lower the value by 20 to 30% at a time.

The setting value should be 70 to 80% of the value where resonance

does not occur.

1 to 999

SV008 VIA Speed loop leading

compensation

1364 is set as a standard. 1900 is set as a standard during SHG

control. Adjust in increments of approx. 100.

Raise the VIA and adjust to improve the contour tracking precision in

high-speed cutting. If the position droop vibrates (10 to 20Hz), lower the

VIA and adjust.

1 to 9999

(0.0687rad/s)

(3) Disturbance observer

The disturbance observer can reduce the effect caused by disturbance, frictional resistance or

torsion vibration during cutting by estimating the disturbance thrust and compensating it. It also is

effective in suppressing the vibration caused by speed leading compensation control.

<Setting method>

1) Adjust VGN1 to the value where vibration does not occur, and then lower it 10 to 20%.

2) Set the total movable mass (including motor mass) (SV037: JL).

3) Set the observer filter band (observer pole) in the disturbance observer 1 (SV043:OBS1), and

estimate the high frequency disturbance to suppress the vibration. Set 600 as a standard.

4) Set the observer gain in disturbance observer 2 (SV044:OBS2). The disturbance observer will

function here for the first time. Set 100 first, and if vibration does not occur, increase the

setting by 50 at a time to increase the observer effect.

5) If vibration occurs, lower OBS1 by 50 at a time. The vibration can be eliminated by lowering

OBS2, but the effect of the disturbance observer can be maintained by keeping OBS2 set to a

high value.

No. Abbrev. Parameter name Unit Explanation Setting range

SV037 JL Total movable mass kg Set the total mass of the moving section with a kg unit.

(Including the motor mass)

0 to 5000

(kg)

SV043 OBS1 Disturbance

observer 1

rad/s Set the observer filter band (observer pole).

Set 600 as a standard, and lower the setting by 50 at a time if

vibration occurs.

0 to 1000

(rad)

SV044 OBS2 Disturbance

observer 2

% Set the observer gain.

Set 100 to 300 as a standard, and lower the setting if

vibration occurs.

0 to 500

(%)