Chapter 11 Troubleshooting

11–12

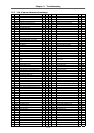

Alarm check timing

f1 f2 f3 f4

Alarm No.

27

Scale CPU error (SUB):

The CPU of the absolute position linear scale connected to the SUB side is not

operating correctly.

–

{ { {

Investigation details Investigation results Remedies

The connector is disconnected (or

loose).

Correctly install. 1 Wiggle the connectors by hand to check

whether the absolute position linear

scale connectors (unit side and scale

side) are disconnected.

The connector is not disconnected. Investigate item 2.

There is a connection fault. Replace the detector cable. 2 Turn the power OFF, and check the

detector cable connection with a tester.

The connection is normal. Investigate item 3.

The alarm is on the unit side. Replace the drive unit. 3 Connect to another normal axis unit,

and check whether the fault is on the

unit side or scale side.

The alarm is on the absolute position

linear scale side.

Investigate item 4.

No abnormality is found in particular. Replace the absolute position linear scale. 4 Check if there is any abnormality in the

unit's ambient environment.

(Ex. Ambient temperature, noise,

grounding)

An abnormality was found in the

ambient environment.

Take remedies according to the causes of

the abnormality.

Ex. High

temperature ... Check the

cooling

fan.

Incomplete grounding …. Additionally

ground.

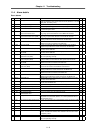

Alarm check timing

f1 f2 f3 f4

Alarm No.

28

Scale overspeed (SUB):

The absolute position liner scale connected to the SUB side detected a speed of

45m/sec or more when the CNC power was turned ON.

–

{

– –

Investigation details Investigation results Remedies

The system is not the absolute position

linear scale specifications.

Correctly set the SV025: MTYP

parameter.

1 Check that the system is an absolute

position linear scale specification

system.

The system is the absolute position

linear scale specifications.

Investigate item 2.

The machine was operating. Check the motor's mechanical brakes and

machine system.

2 Check whether the machine was

operating when the alarm occurred.

The machine was not operating. Investigate item 3.

The connector is disconnected (or

loose).

Correctly install. 3 Wiggle the connectors by hand to check

whether the absolute position linear

scale connectors (unit side and scale

side) are disconnected.

The connector is not disconnected. Investigate item 4.

There is a connection fault. Replace the detector cable. 4 Turn the power OFF, and check the

detector cable connection with a tester.

The connection is normal. Investigate item 5.

The alarm is on the unit side. Replace the drive unit. 5 Connect to another normal axis unit,

and check whether the fault is on the

unit side or detector side.

The alarm is on the absolute position

linear scale side.

Investigate item 6.

No abnormality is found in particular. Replace the absolute position linear scale. 6 Check if there is any abnormality in the

unit's ambient environment.

(Ex. Ambient temperature, noise,

grounding)

An abnormality was found in the

ambient environment.

Take remedies according to the causes of

the abnormality.

Ex. High

temperature ... Check the

cooling

fan.

Incomplete grounding .... Additionally

ground.

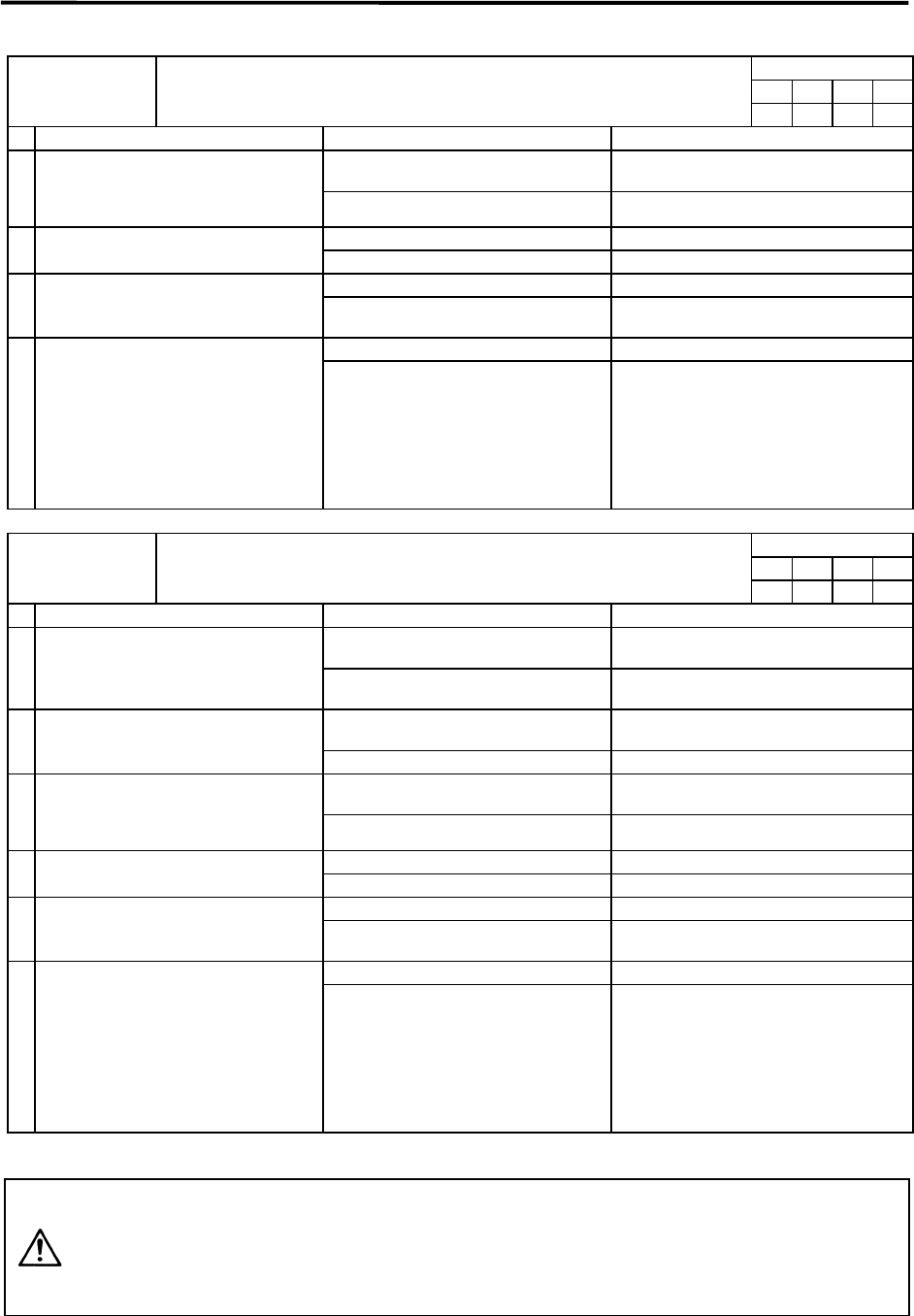

CAUTION

To prevent trouble, when changing the motor and driver combination, avoid

driving a driver with a larger capacity than the specified driver using the motor.

The motor could be demagnetized. Note that this combination can be used for

checking in the emergency stop state. The motor can be driven with a driver

with a capacity smaller than the specifications.