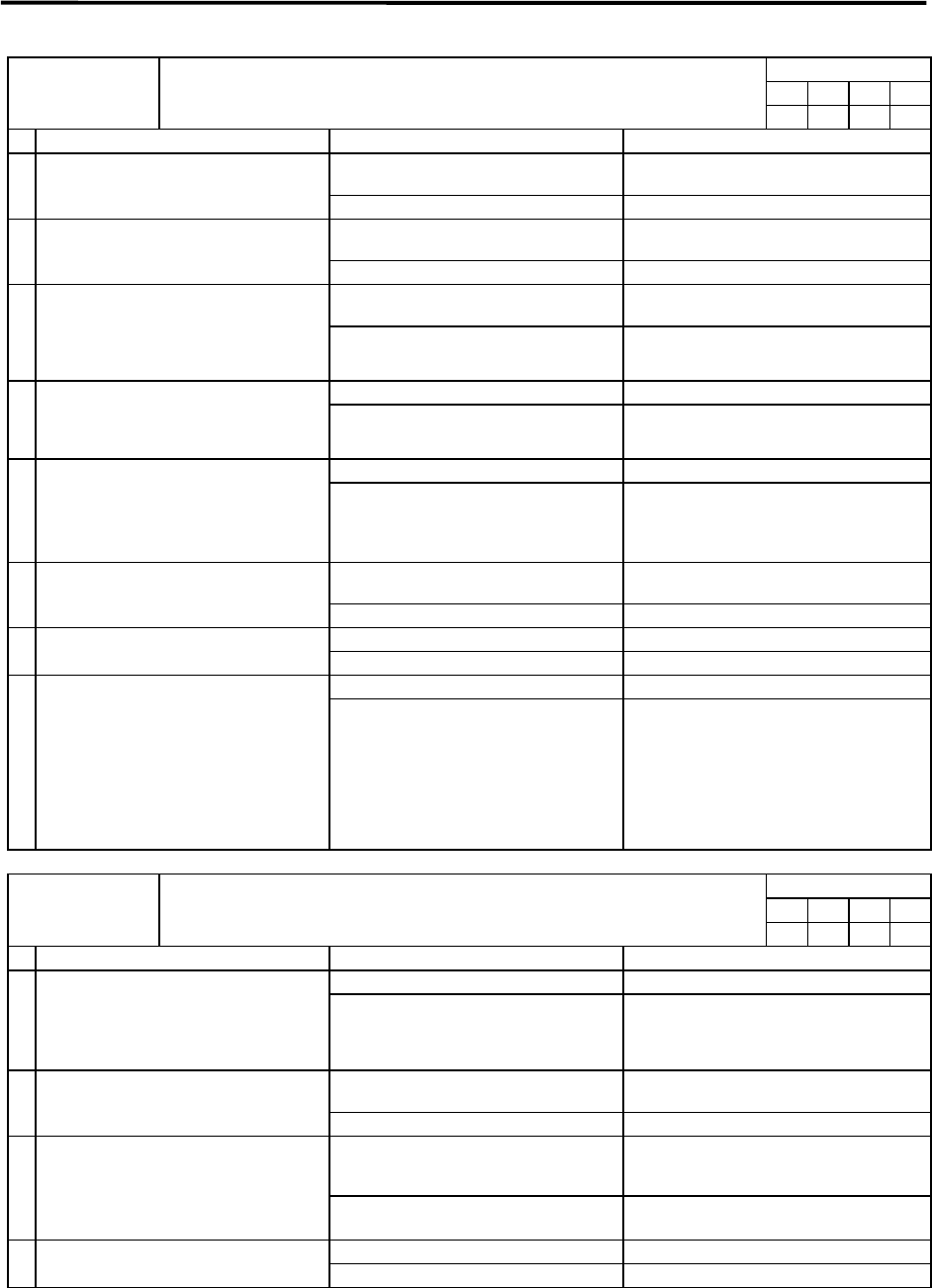

Chapter 11 Troubleshooting

11–23

Alarm check timing

f1 f2 f3 f4

Alarm No.

53

Excessive error 2:

The difference of the ideal position and actual position exceeded parameter

SV026:OD2 at servo OFF.

–

{

– –

Investigation details Investigation results Remedies

The value differs from the standard

setting value.

When not using special specifications, set

the value to the standard setting value.

1 Check the servo parameter (OD2)

setting value.

The value is the standard setting value. Investigate item 2.

The machine was operating. Check the machine and mechanical

brakes.

2 Check whether the machine is moving

during servo OFF.

The machine was not operating. Investigate item 3.

The connector is disconnected (or

loose).

Correctly install. 3 Wiggle the communication cable

between the CNC and final connector

by hand to check whether the detector

connectors (unit side and CNC side) are

disconnected.

The connector is not disconnected. Investigate item 4.

There is a connection fault. Replace the communication cable. 4 Turn the power OFF, and check the

communication cable connection with a

tester.

Try replacing with normal cables.

The connection is normal. Investigate item 5.

The alarm is on the unit side. Replace the drive unit. 5 Replace with another normal axis unit,

and check whether the fault is in the

unit.

The alarm occurs even when the unit is

replaced.

Replace the MCP card on the CNC side.

↓

If the problem is not resolved, check

investigation item 6.

The connector is disconnected (or

loose).

Correctly install. 6 Wiggle the connectors by hand to check

whether the detector connectors (unit

side and motor side) are disconnected.

The connector is not disconnected. Investigate item 7.

There is a connection fault. Replace the detector cable. 7 Turn the power OFF, and check the

detector cable connection with a tester.

The connection is normal. Investigate item 8.

No abnormality is found in particular. Replace the motor. 8 Check if there is any abnormality in the

unit's ambient environment.

(Ex. Ambient temperature, noise,

grounding)

An abnormality was found in the

ambient environment.

Take remedies according to the causes of

the abnormality.

Ex. High

temperature ... Check the

cooling

fan.

Incomplete grounding .... Additionally

ground.

Alarm check timing

f1 f2 f3 f4

Alarm No.

54

Excessive error 3:

The motor current is not flowing when the excessive error alarm 1 was detected.

–

{ {

–

Investigation details Investigation results Remedies

The voltage is being supplied. Investigate item 3. 1 Check whether the PN power is

supplied to the driver.

•

Check the axis for which the alarm is

occurring and the axis farthest from

the power supply.

The voltage is not being supplied. Investigate item 2.

There is no voltage at the PN terminal.

(The lamp is not lit.)

Check the power supply unit. 2 Check whether the power supply unit's

CHARGE lamp is lit, and the PN

terminal voltage.

There is voltage at the PN terminal. Check the PN wiring between the units.

The power line is not connected or is

disconnected.

Increase the acceleration/deceleration

time constant to lower to approx. 80% of

the limit value.

3 Check whether the motor power line is

connected to the motor.

•

Disconnect the power line from the

terminal block, and check between

UVW with a tester.

The power line is correctly connected. Investigate item 4.

The alarm is on the unit side. Replace the drive unit. 4 Replace with another normal unit, and

check whether the fault is in the unit.

The alarm is on the motor side. Replace the motor.