Chapter 7 Installation

7–8

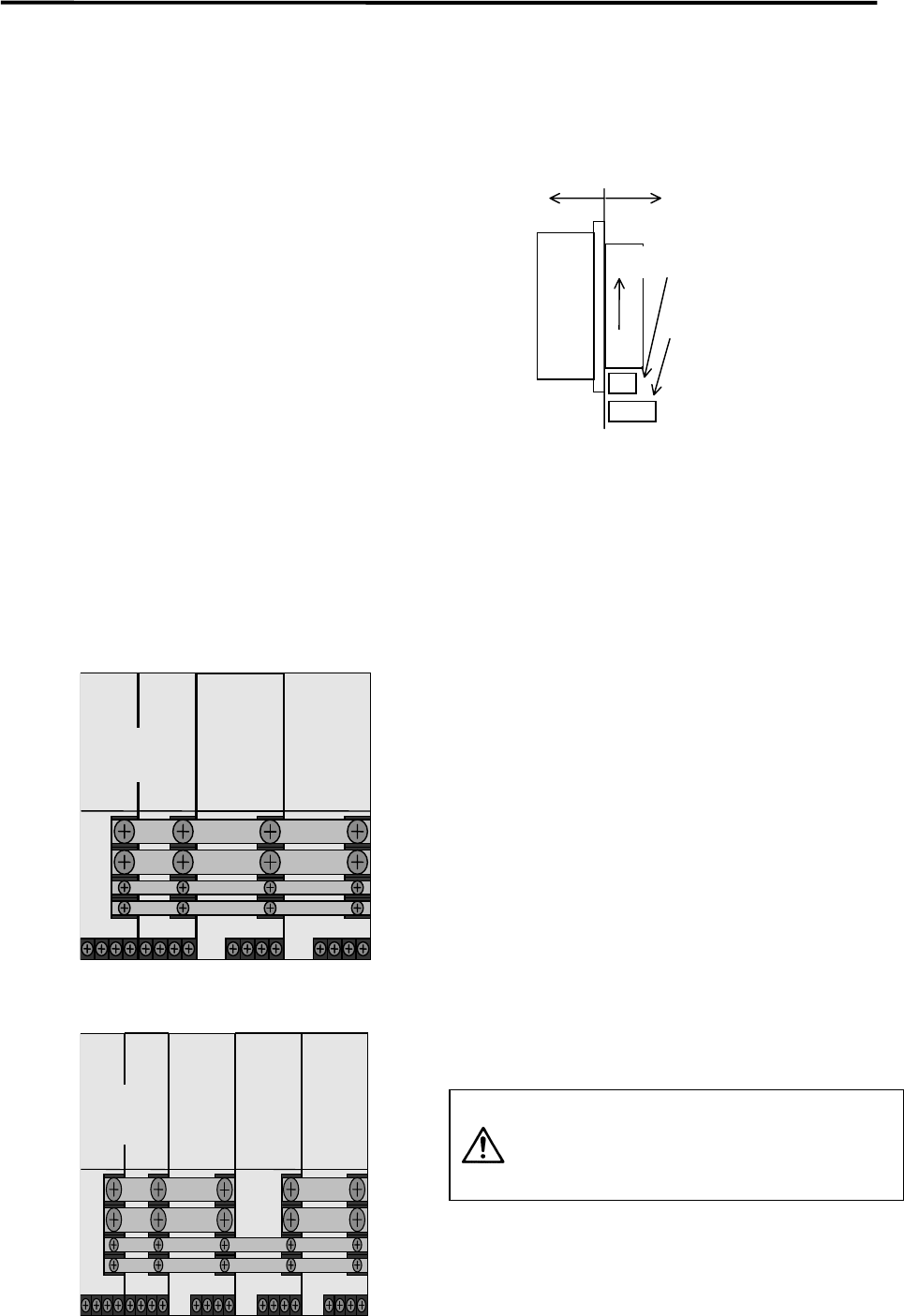

(5) Installing the cooling fan

1) Each unit (excluding type without fins) is provided with a cooling fan (FAN1 below). However,

to maintain operation when the fan stops due to deterioration of the fan's ambient

environment, and to improve the serviceability, the user should install an additional fan (FAN2

below).

When using the sealed type unit installation

method and the panel structure could easily

allow cutting oil or dust to enter from the unit's

fin and fan section (in other words, when the

fan could stop due to the ambient environment),

the user should add a fan at the position shown

as FAN2 on the right. Carry out forced cooling

with a velocity of 2m/s or more. The

serviceability must also be considered in this

case.

2) Due to the structure, heat will easily accumulate in each unit. Thus, install a fan in the power

distribution panel to agitate the heat at the top of the unit.

7-2-4 Layout of each unit

Principally, the following layout is used as the standard.

1) When total of spindle motor output and servomotor output is 38kW or less

Servo

drive unit

2) When total of spindle motor output and servomotor output is 38kW or more

(Note) As a principle, keep the clearance between each unit at 3cm or less.

If the clearance between the spindle drive unit and servo drive unit must be 3cm or more,

observe the conditions given in section 7-2-8.

CAUTION

Always connect the L+ and

L– link bars of power supply

No. 1 and No. 2

independently.

Inside

panel

Outside

panel

Wind

direction

FAN1

(Mounted as a standard on

unit)

FAN2

(Additionally installed by user)

... Install a finger cover for

safety purposes.

L+

L–

L1+

L1–

Power

supply

unit

Spindle

drive unit

L+

L–

L1+

L1–

Power

supply

unit No.1

Spindle

drive

unit

Servo

drive

unit

Power

supply

unit No.2