Chapter 11 Troubleshooting

11–32

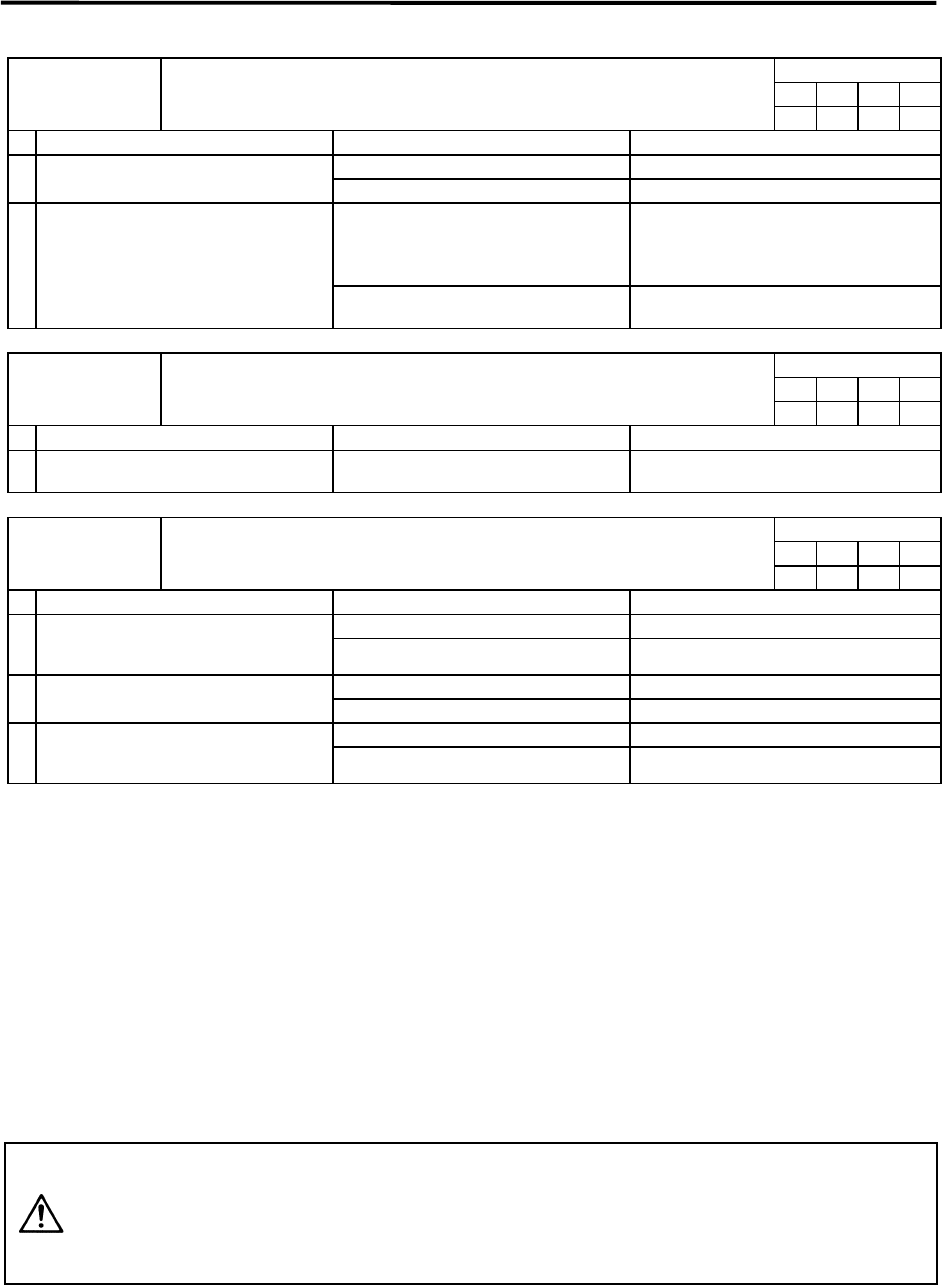

Alarm check timing

f1 f2 f3 f4

Alarm No.

E1

Overload warning:

An level 80% of the overload alarm 1 was detected.

–

{ { {

Investigation details Investigation results Remedies

The motor is not hot. Check the alarm No. "50" items. 1 Check whether the motor is hot.

The motor is hot. Investigate item 2.

Operation is possible without problem. 1. If possible, ease the operation pattern.

2. If an alarm does not occur with

continued operation, continue in this

state.

2 Check whether there is a problem

during acceleration/deceleration

operation.

There is a problem in the operation. Check investigation items 3 and following

of alarm No. "50".

Alarm check timing

f1 f2 f3 f4

Alarm No.

E4

Parameter error warning:

A parameter exceeding the setting range was set.

–

{ {

–

Investigation details Investigation results Remedies

1 Set the correct values following the

parameter adjustment procedures.

Alarm check timing

f1 f2 f3 f4

Alarm No.

E7

CNC emergency stop:

An emergency stop signal is being sent from the CNC, or an alarm is occurring in

another axis.

–

{ { {

Investigation details Investigation results Remedies

The emergency stop state is entered. Investigate item 2. 1 Check whether the CNC side

emergency stop switch has been

applied.

Emergency stop has been canceled. Investigate item 3.

Operation starts normally. Normal 2 Cancel the emergency stop.

"E7" remains displayed. Investigate item 3.

Pinpoint the cause of the fault. Correct the fault. 3 Check whether the terminator or battery

unit is connected, or whether these are

loose.

Normal Check the alarm No. "34" items.

CAUTION

To prevent trouble, when changing the motor and driver combination, avoid

driving a driver with a larger capacity than the specified driver using the motor.

The motor could be demagnetized. Note that this combination can be used for

checking in the emergency stop state. A driver with a capacity smaller than the

specifications can be driven with the motor.