Chapter 10 Adjustment

10–39

Details of parameters

No.

Abbrev.

Details

Setting range

(Unit)

SV001 PC1 Set 1 for the linear motor system. 1 to 32767

SV002 PC2 Set 1 for the linear motor system. 1 to 32767

SV003 PGN1 Set the position loop gain in increments of 1.

Normally, 47 is set.

1 to 200

(rad/s)

SV004 PGN2 When carrying out SHG control, set together with SV057: SHGC.

Normally, 0 is set when not using 125.

0 to 999

(rad/s)

SV005 VGN1 Set the speed loop gain.

150 is set as a standard. If increased, the response will increase but the vibration and noise

will increase.

1 to 999

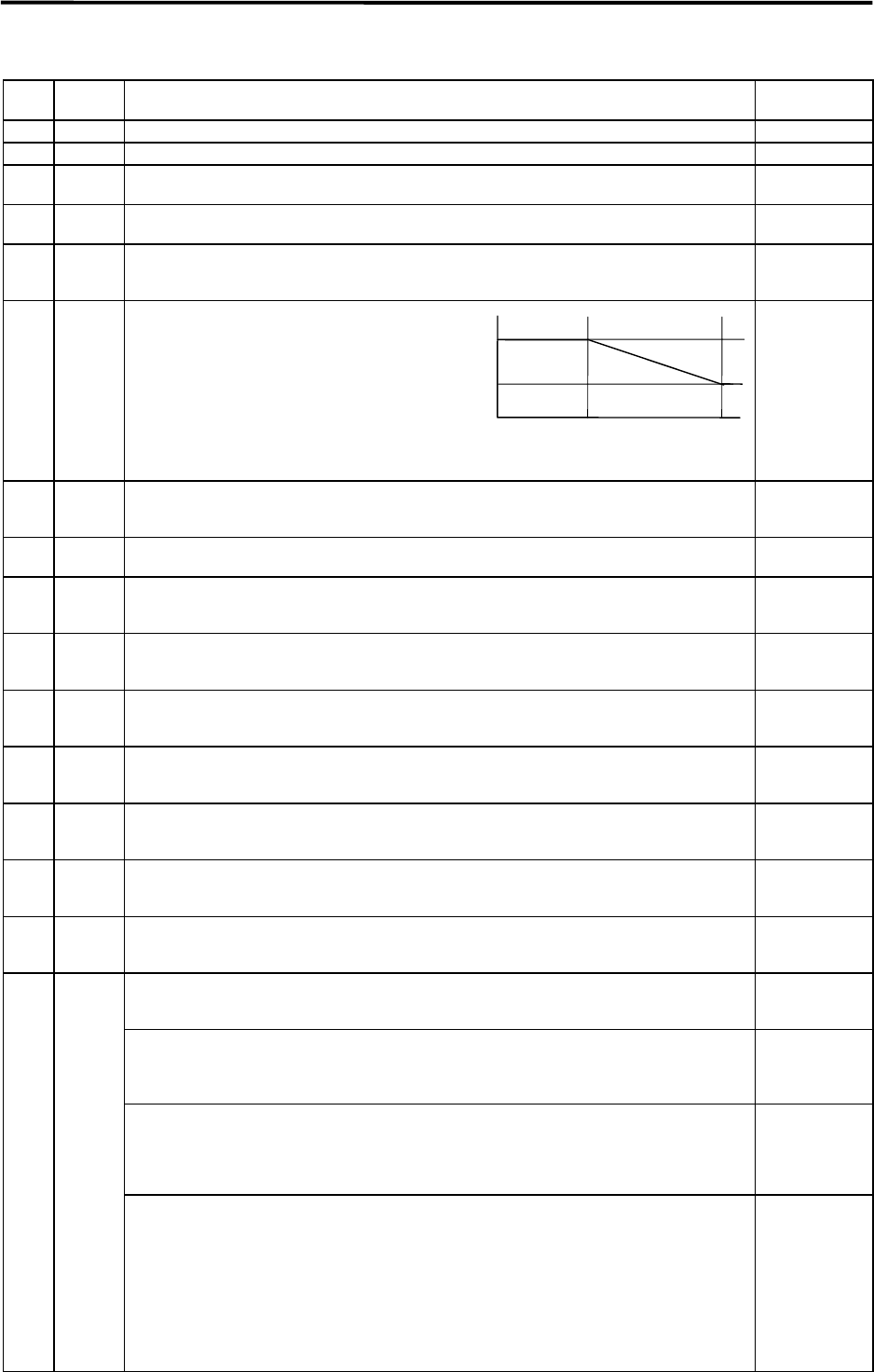

SV006 VGN2 If the noise is bothersome at high speeds,

such as during rapid traverse, set the speed

loop gain (smaller than VGN1) for high speeds

(1.2-times the rated speed).

The speed to start dropping the speed gain is

set with SV029:VCS.

Set 0 when not using this function.

–1000 to 1000

SV007 VIL Set this when a limit cycle occurs, of if overshooting occurs during positioning.

Set 0 when not using this function.

Related parameters: SV027:SSF1/vcnt1, vcnt2

0 to 32767

SV008 VIA Set the speed loop advance compensation. 1 to 9999

(0.0687rad/s)

SV009 IQA Set the current loop internal compensation.

The setting value is fixed according to the motor being used. (Refer to section 9-2-4 List of

standard parameters for each motor.)

1 to 20480

SV010 IDA Set the current loop internal compensation.

The setting value is fixed according to the motor being used. (Refer to section 9-2-4 List of

standard parameters for each motor.)

1 to 20480

SV011 IGQ Set the current loop internal compensation.

The setting value is fixed according to the motor being used. (Refer to section 9-2-4 List of

standard parameters for each motor.)

1 to 4096

SV012 IDG Set the current loop internal compensation.

The setting value is fixed according to the motor being used. (Refer to section 9-2-4 List of

standard parameters for each motor.)

1 to 4096

SV013 ILMT Set the current limit value as a percentage (%) in respect to the stall rated current.

To use to the driver's max. thrust, set 800. (Limit value in both + and – directions.)

0 to 999

(Stall rated

current %)

SV014 ILMTsp Set the current limit value for special operations (absolute position default setting, stopper

operation, etc.) as a percentage (%) in respect to the stall rated current.

To use to the driver's max. thrust, set 800. (Limit value in both + and – directions.)

0 to 999

(Stall rated

current %)

SV015 FFC Set this when the overshooting amount during feed forward control, or the relative error during

synchronous control, etc., is large.

Set to 0 when not using this function.

0 to 999

(%)

Set this parameter if the protrusion (caused by non-sensitive band from friction, torsion,

backlash, etc.) is large when the arc quadrant is changed.

This is valid only when lost motion compensation (SV027: lmc1, lmc2) are selected.

–1 to 200

Type 1

SV027:SSF1/lmc1=1/lmc2=0

Protrusions during low-speed interpolation can be eliminated with this type of compensation.

The compensation gain will be 0 when 0 is set. 100% compensation will be carried out when

100 is set.

0 to 200

(%)

Type 2

SV027:SSF1/lmc1=0/lmc2=1

This type is the standard for the MDS Series.

Use this type during high-speed high-accuracy interpolation if sufficient compensation is not

possible with type 1.

Set as a percentage (%) in respect to the stall rated current.

0 to 100

(Stall rated

current %)

SV016 LMC1

To change the compensation gain (type 1) or compensation amount (type 2) according to the

direction.

To set a different value according to the command direction, set this in addition to SV041:

LMC2.

Set the value for changing the command speed from the – to + direction (during command

direction CW) in SV016:LMC1.

Set the value for changing the command speed from the + to – direction (during command

direction CW) in SV041:LMC2.

When –1 is set, compensation will not be carried out when the command speed direction

changes.

(Motor rated speed × 1.2)

VLM 0

VGN2

VGN1

VCS