Chapter 10 Adjustment

10–19

10-3-5 Improvement of overshooting

The phenomenon when the machine position goes past or exceeds the command during feed

stopping is called overshooting. Overshooting is compensated by overshooting compensation (OVS

compensation).

Overshooting occurs due to the following two causes.

1) Machine system torsion: Overshooting will occur mainly during rapid traverse positioning

2) Machine system friction: Overshooting will occur mainly during one pulse feed

Either phenomenon can be confirmed by measuring the position droop.

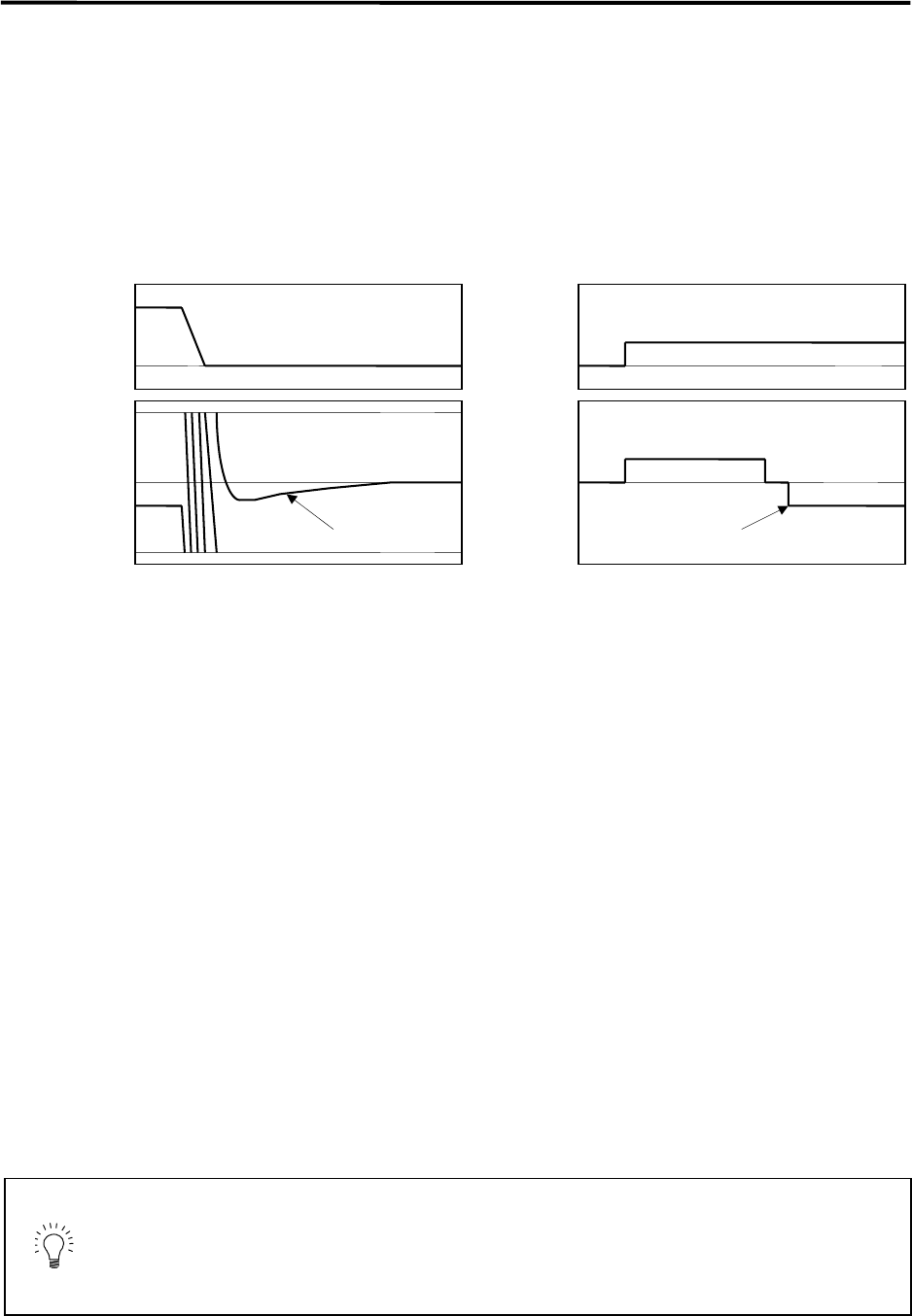

1) Overshooting during rapid traverse positioning 2) Overshooting during pulse feed

(1) Overshooting compensation (OVS compensation)

In OVS compensation, the overshooting is suppressed by subtracting the thrust command set in

the parameters when the motor stops. There are two types of OVS compensation. The standard

method is type 2.

OVS compensation type 3 has a compensation effect for the overshooting during either rapid

traverse positioning or pulse feed. Note that there is no compensation if the next feed command

has been issued before the motor positioning (stop). (Therefore, there is no compensation during

circle cutting.) There is no compensation in the non-sensitive band when the CNC is carrying out

feed forward control. To compensate overshooting during feed forward control, refer to the

following section "(2) Adjusting for feed forward control".

<Setting and adjustment methods>

1) Set the special servo function selection 1 (SV027:SSF1) bit 11 (ovs2). (OVS compensation

type 2 will start.)

2) Observe the position droop waveform using the D/A output, and increase the overshoot

compensation 1 (SV031: OVS1) value 1% at a time. Set the smallest value where the

overshooting does not occur. If SV042:OVS2 is 0, the overshooting will be compensated in

both the positive/negative directions with the OVS1 setting value.

3) If the compensation amount is to be changed in the direction to be compensated, set the +

direction compensation value in OVS1 and the – direction compensation value in OVS2. If only

one direction is to be compensated, set the side not to be compensated as -1. The

compensation direction setting will be as reversed with the CNC parameter CW/CCW setting.

POINT

In OVS compensation type 2, there is no compensation in the following cases.

1. There is no compensation if the next feed command has been issued before

the motor positioning (stop). (There is no compensation in circle cutting.)

2. There is no compensation when the CNC is carrying out feed forward (fwd)

control.

0

Position

command

0

Position

droop

Time

Overshoot

0

Speed

FB

0

Position

droop

Time

Overshoot