Chapter 2 Drive System Configuration

2–9

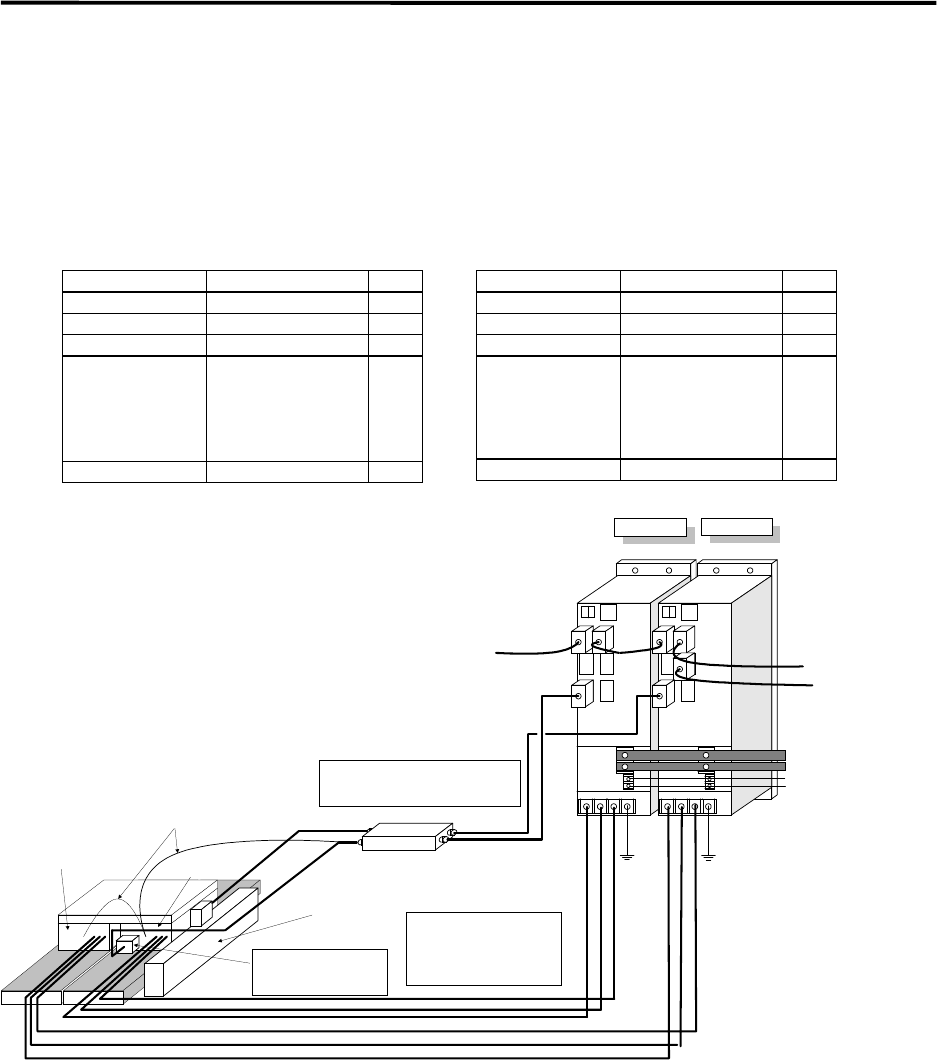

(2) 1-scale 2-motor (2-amplifier) control

When using only one linear scale to detect the position, if this linear scale is an incremental scale,

the pole position of each motor cannot be detected independently. Thus, the motor installation

position on the master side and slave side must be mechanically aligned.

If the linear scale is an absolute position scale, the pole position of each motor can be set

independently in the CNC as an absolute position even when only one linear scale is being used.

However in this case, DC excitation must be carried out with only one motor, so this method is

limited to when the axis can be driven with one motor (possible if low-speed drive) is possible.

MDS-B-V14L

CN4

CN1B CN1B

CN4

CN3

CN3

L+

L–

Single-phase

200VAC

UVW

CON3

CON4

CON1

CON2

Linear scale

CN2

CN1A

CN2

Master axis

MDS-B-V14L

Slave axis

To next axis,

terminator or

battery unit

To power supply

if final axis

To NC or

previous axis

Linear motor

primary side

(Slave)

Motor thermal

signal

Linear motor primary

side (Master)

Analog voltage output type

incremental scale or

AT342 (Mitsutoyo)

absolute position scale

Pole detector

(MDS-B-MD-600)

* Not required for the AT342

scale

Scale I/F

(Incremental scale : MDS-B-HR-12M)

(AT342 scale : MDS-B-HR-22M)

Incremental system

Unit name Type Qty.

Linear servomotor LM-NP- 2

Servo driver MDS-B-V14L- 2

Linear scale LS186, LIDA181 etc. 1

Scale I/F unit MDS-B-HR-12M

1

Pole detection unit MDS-B-MD-600 1

Absolute system

Unit name Type Qty.

Linear servomotor LM-NP- 2

Servo driver MDS-B-V14L- 2

Linear scale AT342 (Special) 1

Scale I/F unit MDS-B-HR-22M

MDS-B-HR-22 can

be used when

detecting the motor

thermal signal with

the NC.

1

Pole detection unit None 0