Chapter 10 Adjustment

10–37

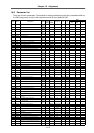

10-6 Parameter list

There are 64 servo parameters. The methods for setting and displaying the servo parameters differ on

the CNC being used, so refer to the instruction manual for the respective CNC.

Class

Name Abbrev. Descriptions

Setting

screen

B-Vx

compa-t

ibility

Chang-i

ng

method

Setting unit

Min.

unit

Max.

unit

Machine

specifica-t

ions

Servo

specifica-t

ions

Adjust-me

nt

SV001 PC1 Motor side gear ratio

Specifi-c

ations

Default 1 32767

SV002 PC2 Machine side gear ratio

Specifi-c

ations

Default 1 32767

SV003 PGN1 Position loop gain 1

Specifi-c

ations

Normal rad/s 1 200

SV004 PGN2 Position loop gain 2

Adjust-m

ent

Normal rad/s 0 999

SV005 VGN1 Speed loop gain 1

Adjust-m

ent

Normal 1 999

SV006 VGN2 Speed loop gain 2 Normal –1000 1000

SV007 VIL Speed loop delay compensation

Adjust-m

ent

Normal 0 32767

SV008 VIA Speed loop leading compensation

Adjust-m

ent

Normal 1 9999

SV009 IQA Current loop q axis compensation Normal 1 20480

SV010 IDA Current loop d axis compensation Normal 1 20480

SV011 IQG Current loop q axis gain Normal 1 4096

SV012 IDG Current loop d axis gain Normal 1 4096

SV013 ILMT Current limit value Normal Stall current % 0 999

SV014 ILMTsp Current limit value during special operation Normal Stall current % 0 999

SV015 FFC Acceleration feed forward gain

Adjust-m

ent

Normal % 0 999

SV016 LMC1 Lost motion compensation 1

Adjust-m

ent

Normal Stall current % –1 200

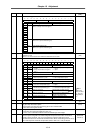

SV017 SPEC Servo specifications

Specifi-c

ations

∆ Default HEX setting ∗ ∗

SV018 PIT Linear motor pole pitch

Specifi-c

ations

Default mm 1 32767

SV019 RNG1 Position detector resolution

Specifi-c

ations

Default kp/PIT 1 9999

SV020 RNG2 Speed detector resolution

Specifi-c

ations

Default kp/PIT 1 9999

SV021 OLT Overload time constant Normal s 1 300

SV022 OLL Overload detection level Normal Stall current % 1 500

SV023 OD1 Excessive error detection width during servo ON Normal mm 0 32767

SV024 INP In-position detection width Normal µm 0 32767

SV025 MTYP Motor/detector type

Specifi-c

ations

∆ Default HEX setting ∗ ∗

SV026 OD2

Excessive error detection width during servo

OFF

Normal mm 0 32767

SV027 SSF1 Special servo function selection 1

Specifi-c

ations

∆ Normal HEX setting ∗ ∗

SV028 MSFT Linear motor pole shift amount Default µm –30000 30000

SV029 VCS Speed loop gain, change start speed Normal mm/s 0 9999

SV030 IVC Current/voltage compensation Normal –32768 32767

SV031 OVS1 Overshooting compensation

Adjust-m

ent

Normal % –1 100

SV032 TOF Thrust offset

Adjust-m

ent

Normal Stall current % –100 100

SV033 SSF2 Special servo function selection 2

Specifi-c

ations

∆ Normal HEX setting ∗ ∗

SV034 SSF3 Special servo function selection 3 Normal HEX setting ∗ ∗

SV035 SSF4 Special servo function selection 4 Normal HEX setting ∗ ∗

SV036 PTYP Power supply type

Specifi-c

ations

Default HEX setting ∗ ∗

SV037 JL Total movable mass during linear motor

Adjust-m

ent

Normal kg 0 5000

SV038 FHz1

Machine resonance suppression filter center

frequency 1

Adjust-m

ent

∆ Normal Hz 0 9000

SV039 LMCD Lost motion compensation timing Normal ms 0 2000

SV040 LMCT

Current compensation/lost motion compensation

non-sensitive band

Adjust-m

ent

Normal –/µm –32768 32767

SV041 LMC2 Lost motion compensation 2

Adjust-m

ent

Normal Stall current % –1 200

SV042 OVS2 Overshooting compensation 2 Normal Stall current % –1 100

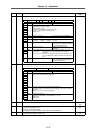

SV043 OBS1 Observer 1 Normal rad 0 1000

SV044 OBS2 Observer 2 Normal % 0 500

SV045 TRUB Current compensation/frictional force Normal

–/Stall

current %

–32768 32767

SV046 FHz2

Machine resonance suppression filter center

frequency 2

Adjust-m

ent

Normal Hz 0 9000

SV047 EC1 Inductive voltage compensation Normal % ∗ ∗

SV048 EMGrt Brake operation delay time Normal ms 0 2000

SV049 PGN1sp Position loop gain 1 during special operation Normal rad/s 1 200

SV050 PGN2sp Position loop gain 2 during special operation Normal rad/s 0 999

SV051 DFBT Normal ms 0 9999

SV052 DFBN Normal µm 0 9999

SV053 OD3

Excessive error detection width during special

operation

Normal mm 0 32767

SV054 ORE CN3 connection system, overrun detection width Normal mm –1 32767