206

Check first when you have a trouble

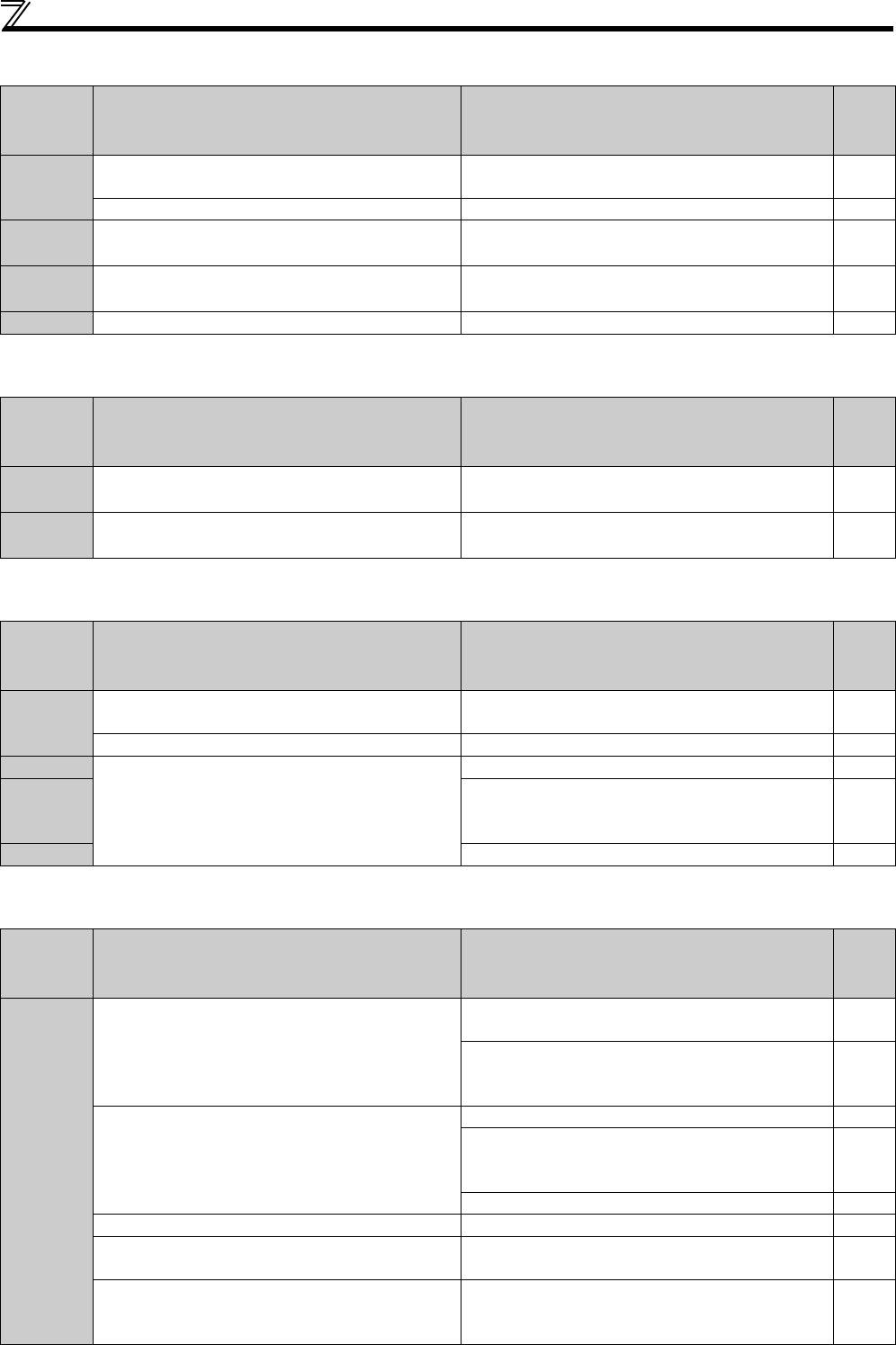

6.5.4 Motor generates heat abnormally

6.5.5 Motor rotates in the opposite direction

6.5.6 Speed greatly differs from the setting

6.5.7 Acceleration/deceleration is not smooth

Check

points

Possible Cause Countermeasures

Refer

to

page

Motor

Motor fan is not working

(Dust is accumulated.)

Clean the motor fan.

Improve the environment.

—

Phase to phase insulation of the motor is insufficient. Check the insulation of the motor. —

Main

Circuit

The inverter output voltage (U, V, W) are unbalanced.

Check the output voltage of the inverter.

Check the insulation of the motor.

213

Parameter

Setting

The Pr. 71 Applied motor setting is wrong. Check the Pr. 71 Applied motor setting.

125

— Motor current is large. Refer to "6.5.11 Motor current is too large" 208

Check

points

Possible Cause Countermeasures

Refer

to

page

Main

Circuit

Phase sequence of output terminals U, V and W is

incorrect.

Connect phase sequence of the output cables (terminal

U, V, W) to the motor correctly

15

Parameter

Setting

Pr. 40 RUN key rotation direction selection setting is

incorrect.

Check the Pr. 40 setting.

182

Check

points

Possible Cause Countermeasures

Refer

to

page

Parameter

Setting

Pr. 1, Pr. 2, Pr. 18 settings are improper.

Check the settings of Pr. 1 Maximum frequency, Pr. 2

Minimum frequency, Pr. 18 High speed maximum frequency.

105

Pr. 31 to Pr. 36 (frequency jump) settings are improper. Narrow down the range of frequency jump.

106

Load

Stall prevention function is activated due to a heavy

load.

Reduce the load weight. —

Parameter

Setting

Set Pr. 22 Stall prevention operation level higher according

to the load. (Setting Pr. 22 too large may result in

frequent overcurrent trip (E.OC).)

101

Motor

Check the capacities of the inverter and the motor. —

Check

points

Possible Cause Countermeasures

Refer

to

page

Parameter

Setting

The base frequency does not match the motor

characteristics.

For V/F control, set Pr. 3 Base frequency and Pr. 47 Second

V/F (base frequency).

107

For Advanced magnetic flux vector control or General-

purpose magnetic flux vector control, set Pr. 84 Rated

motor frequency.

127

Stall prevention function is activated due to a heavy

load.

Reduce the load weight. —

Set Pr. 22 Stall prevention operation level higher according

to the load. (Setting Pr. 22 too large may result in

frequent overcurrent trip (E.OC).)

101

Check the capacities of the inverter and the motor. —

Acceleration/deceleration time is too short. Increase acceleration/deceleration time.

116

Torque boost (Pr. 0, Pr. 46) setting is improper under V/F

control, so the stall prevention function is activated.

Increase/decrease Pr. 0 Torque boost setting value by

0.5% increments to the setting.

94

Regeneration avoidance operation is performed

If the frequency becomes unstable during regeneration

avoidance operation, decrease the setting of Pr. 886

Regeneration avoidance voltage gain.

174