17

2

WIRING

Main circuit terminal specifications

2.2.3 Cables and wiring length

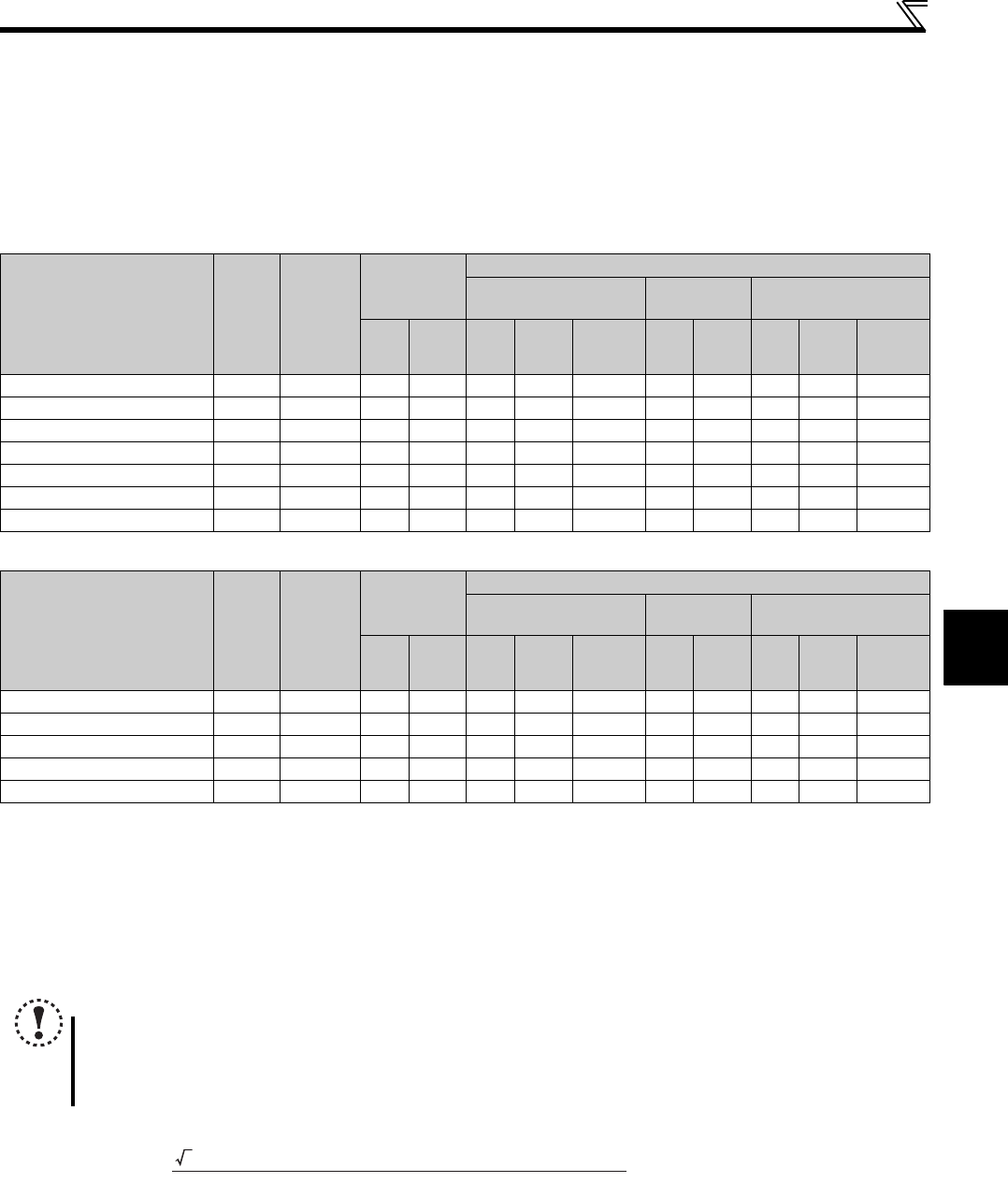

(1) Applicable cable size

Select the recommended cable size to ensure that a voltage drop will be 2% or less.

If the wiring distance is long between the inverter and motor, a main circuit cable voltage drop will cause the motor torque to

decrease especially at the output of a low frequency.

The following table indicates a selection example for the wiring length of 20m.

Three-phase 200V class (when input power supply is 220V)

Three-phase 400V class (when input power supply is 440V)

∗1

The cable size is that of the cable (HIV cable (600V class 2 vinyl-insulated cable) etc.) with continuous maximum permissible temperature of 75°C. Assumes

that the surrounding air temperature is 50°C or less and the wiring distance is 20m or less.

∗2

The recommended cable size is that of the cable (THHW cable) with continuous maximum permissible temperature of 75°C. Assumes that the surrounding air

temperature is 40°C or less and the wiring distance is 20m or less. (Selection example for use mainly in the United States.)

∗3

The recommended cable size is that of the cable (PVC cable) with continuous maximum permissible temperature of 70°C. Assumes that the surrounding air

temperature is 40°C or less and the wiring distance is 20m or less. (Selection example for use mainly in Europe.)

∗4

The terminal screw size indicates the terminal size for R/L1, S/L2, T/L3, U, V, W, and a screw for earthing (grounding).

A screw for earthing (grounding) of the FR-E720-15KNF is indicated in ( ).R/L1, S/L2P/N/

The line voltage drop can be calculated by the following formula:

Line voltage drop [V]=

Use a larger diameter cable when the wiring distance is long or when it is desired to decrease the voltage drop (torque

reduction) in the low speed range.

Applicable Inverter

Model

Terminal

Screw

Size ∗4

Tightening

Torque

N

·

m

Crimping

Terminal

Cable Size

HIV Cables, etc. (mm

2

)

∗1

AWG ∗2

PVC Cables, etc. (mm

2

)

∗3

R/L1

S/L2

T/L3

U, V, W

R/L1

S/L2

T/L3

U, V, W

Earthing

cable

R/L1

S/L2

T/L3

U, V, W

R/L1

S/L2

T/L3

U, V, W

Earthing

cable

FR-E720-0.1KNF to 0.75KNF M3.5 1.2 2-3.5 2-3.5 2 2 2 14 14 2.5 2.5 2.5

FR-E720-1.5KNF, 2.2KNF M4 1.5 2-4 2-4 2 2 2 14 14 2.5 2.5 2.5

FR-E720-3.7KNF M4 1.5 5.5-4 5.5-4 3.5 3.5 3.5 12 12 4 4 4

FR-E720-5.5KNF M5 2.5 5.5-5 5.5-5 5.5 5.5 5.5 10 10 6 6 6

FR-E720-7.5KNF M5 2.5 14-5 8-5 14 8 5.5 6 8 16 10 6

FR-E720-11KNF M5 2.5 14-5 14-5 14 14 14 6 6 16 16 16

FR-E720-15KNF M6(M5) 4.4 22-6 22-6 22 22 14 4 4 25 25 16

Applicable Inverter

Model

Terminal

Screw

Size ∗4

Tightening

Torque

N

·

m

Crimping

Terminal

Cable Size

HIV Cables, etc. (mm

2

)

∗1

AWG ∗2

PVC Cables, etc. (mm

2

)

∗3

R/L1

S/L2

T/L3

U, V, W

R/L1

S/L2

T/L3

U, V, W

Earthing

cable

R/L1

S/L2

T/L3

U, V, W

R/L1

S/L2

T/L3

U, V, W

Earthing

cable

FR-E740-0.4KNF to 3.7KNF M4 1.5 2-4 2-4 2 2 2 14 14 2.5 2.5 2.5

FR-E740-5.5KNF M4 1.5 5.5-4 2-4 3.5 2 3.5 12 14 4 2.5 4

FR-E740-7.5KNF M4 1.5 5.5-4 5.5-4 3.5 3.5 3.5 12 12 4 4 4

FR-E740-11KNF M4 1.5 5.5-4 5.5-4 5.5 5.5 8 10 10 6 6 10

FR-E740-15KNF M5 2.5 8-5 8-5 8 8 8 8 8 10 10 10

NOTE

Tighten the terminal screw to the specified torque. A screw that has been tighten too loosely can cause a short circuit

or malfunction. A screw that has been tighten too tightly can cause a short circuit or malfunction due to the unit

breakage.

Use crimping terminals with insulation sleeve to wire the power supply and motor.

3 × wire resistance[mΩ/m] × wiring distance[m] × current[A]

1000